1

2

3

4

Removing and installing piston with connecting rod

105

Removing piston with connecting rod

D Remove oil pan, oil suction pipe, see page 53

D Remove cylinder heads, see page 79

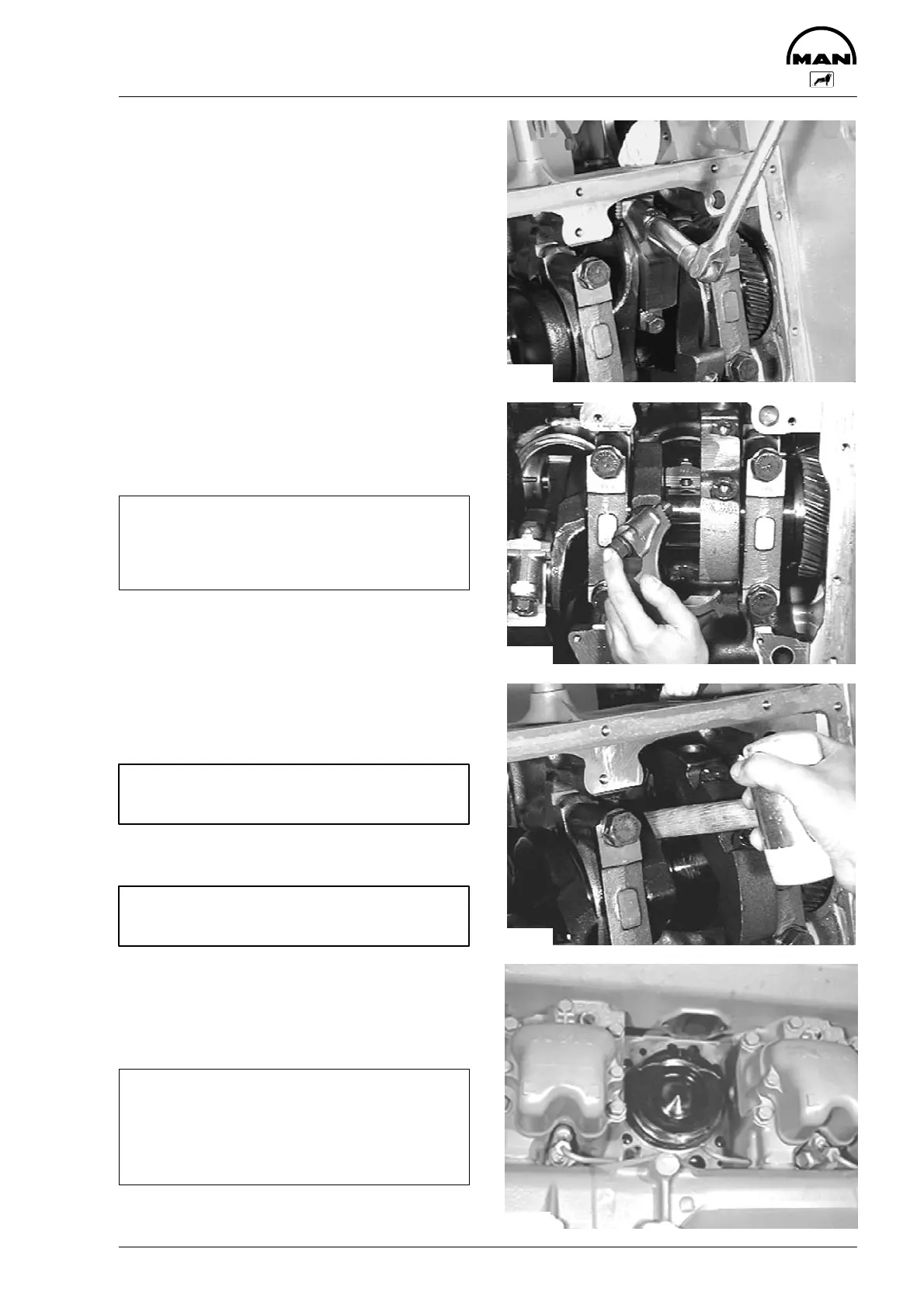

Fig. 1

Remove bolts from connecting rod bearing cap.

Fig. 2

Take off connecting rod bearing caps with bearing

shells, expediting the procedure by means of light

strokes with a synthetic hammer if necessary.

Note:

Connecting rod bearing caps are match-

marked with the connecting rod big ends;

arrange them in corresponding order.

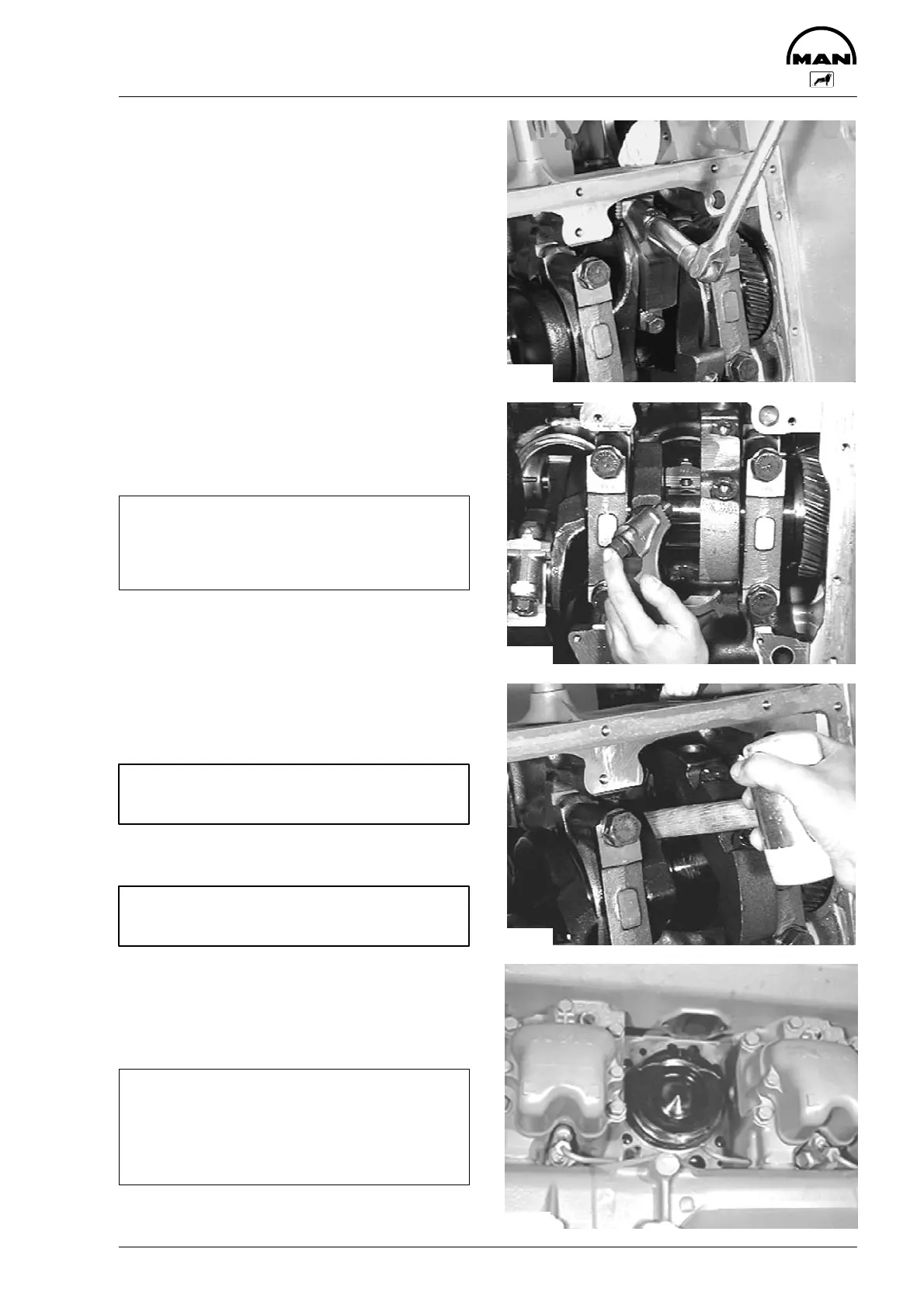

Fig. 3

Remove combustion residues (oil carbon) from top

cylinder edge using a piece of hard wood.

Caution:

Do not damage cylinder liners.

Push out connecting rod with piston in upward

direction.

Caution:

Do not damage oil spray nozzles.

Fig. 4

Lay pistons with connecting rods and associated

caps aside; use deposit rack if available.

Inspect pistons and piston rings visually.

Note:

For reworked crankcase sealing faces repair

pistons with undersizes of 0.2, 0.4 and 0.6

mm in the compression height are available

(see ”Engineering S Data S Setting values”).

3724

3553

3554

3555

Loading...

Loading...