3-15

B

EVERY 50 HOURS OF OPERATION

Perform the operations described above as well as the following operations.

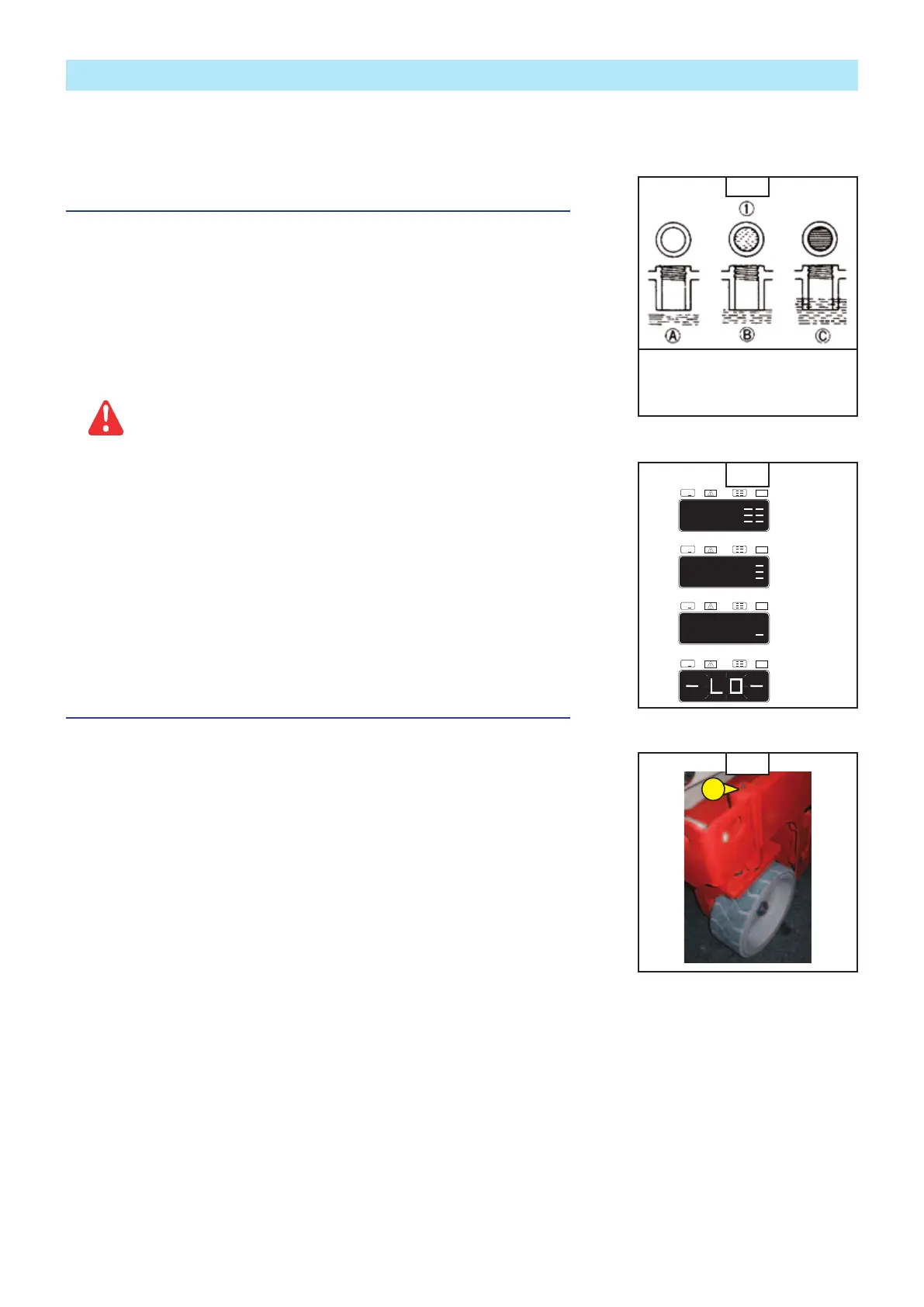

B1 - Battery electrolyte level

CHECK

- Check the electrolyte level in each element of the battery.

- Ensure that every electrolyte level is at the bottom of the ventilation well (Fig. B1-1)

- If the ambient temperature is high, check the level more often than every 50 hours of

operation.

Manipulating and maintaining a battery can be dangerous; take the

following precautions:

- Wear protective goggles.

- Wear gloves

- Keep the battery horizontal when manipulating it.

- Never smoke or work close to a naked flame.

- Work in a sufficiently well-ventilated area.

- If any electrolyte splashes onto your skin, thoroughly rinse the area

with cold water for 15 minutes and call a doctor.

-

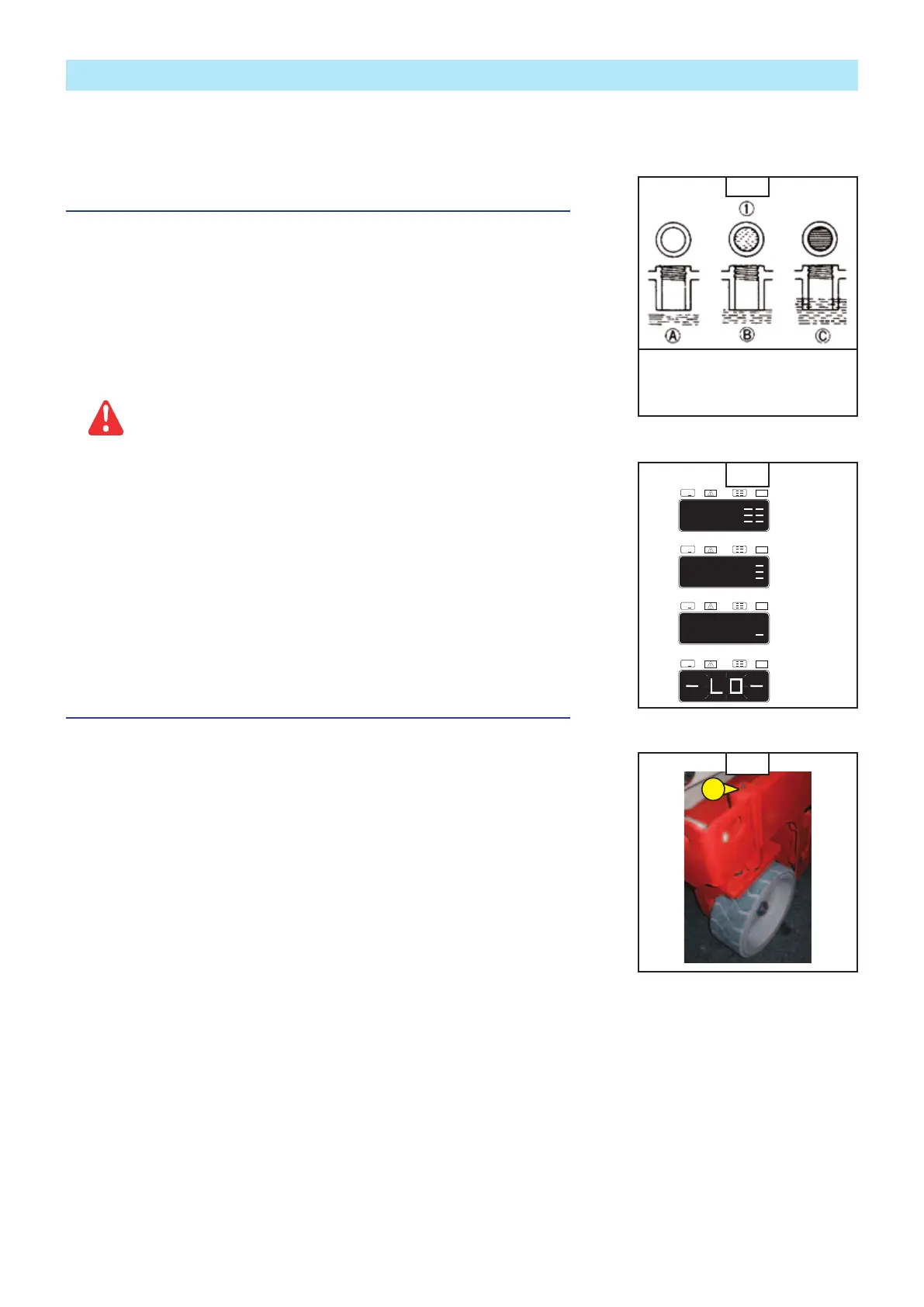

Battery level indicator: use the Diagnostic LED to determine the level in the batteries

(Fig. B1-2).

- Remarks: when the code “LO” flashes on the lifting platform’s LED control screen,

put the machine out of service and charge the batteries; otherwise all the machine’s

functions will be deactivated.

B2 - Steering pivot axes

GREASE

- Clean, then grease the grease points Rep.1 (Fig.2), (See chapter “LUBRICANTS”) and

remove any surplus.

==

+

-

+

-

==

+

-

+

-

==

+

-

+

-

Pleine charge

Mi-charge

Charge faible

==

+

-

+

-

« LO » clignote

B1-2

B2

1

B1-1

(1) Battery electrolyte level

(A) Too low - (B) Moderate

(C) Too high

647369 (01/03/2017)

78/100 SEC 2 / 120 SE 2

Loading...

Loading...