Manitowoc Published 05-15-17, Control # 043-09 4-63

999 LUFFING JIB OPERATOR MANUAL SETUP AND INSTALLATION

Anchoring Wire Rope to Wedge Socket

See Figure 4-37 for the following procedure.

1. Assemble wire rope and wedge to socket so live end of

wire rope is in a straight line with socket pin hole. Do not

assemble WRONG as shown.

2. Allow dead end of wire rope to extend past end of socket

amount shown.

3. Allow wire rope to assume its natural lay.

4. Pull against wedge and live end of wire rope enough to

tighten wedge in socket.

Use a brass hammer to seat wedge and wire rope as

deep into socket as possible.

5. Attach a wire rope clip to dead end of wire rope using

one of the RIGHT methods shown. Rope clip will aid in

preventing wire rope from being pulled out of socket.

NOTE: Use Right Method A only if wire rope clip is small

enough to be securely tightened to dead end. Right

Method C is only for a terminator wedge socket.

CAUTION!

Wire Rope Damage!

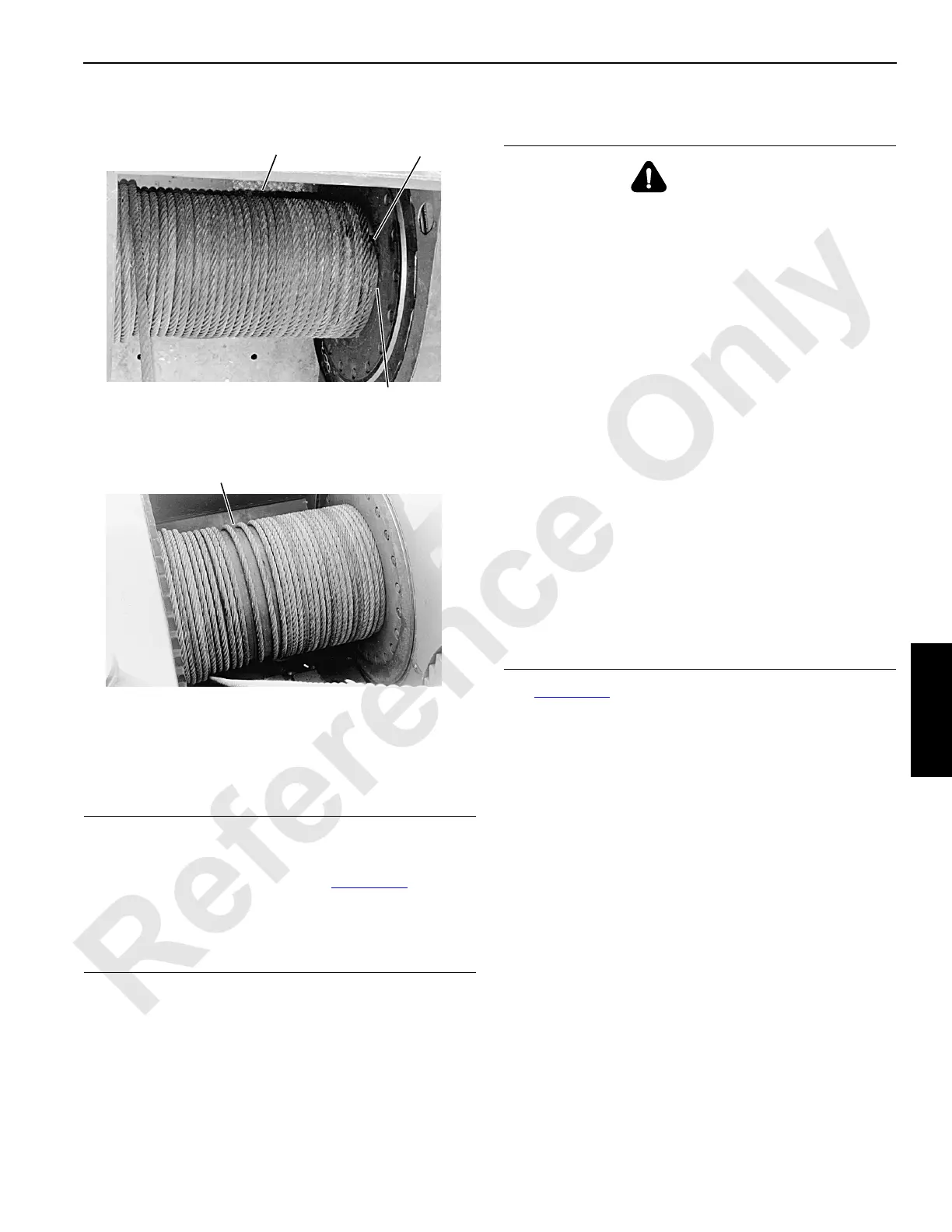

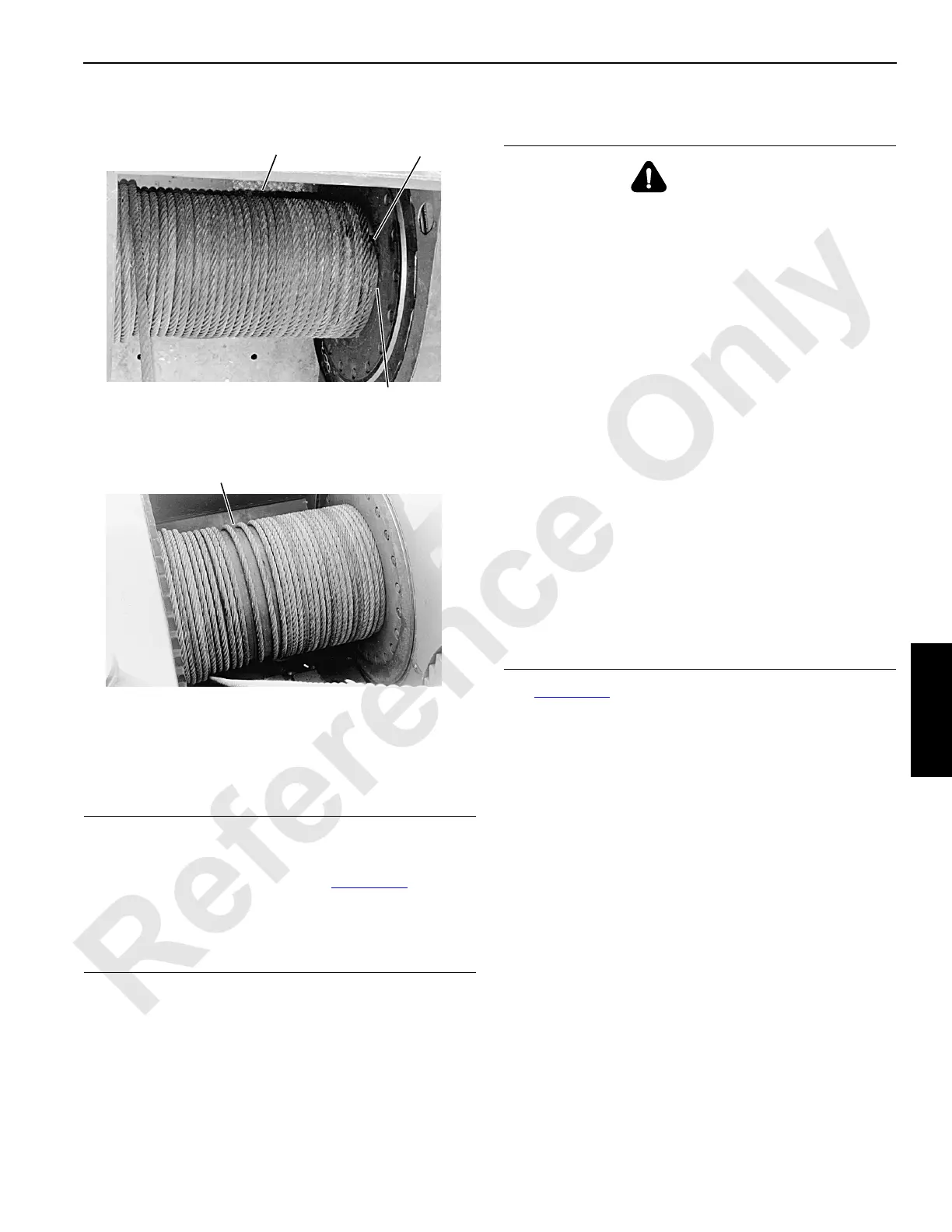

Voids or spaced wraps in first layer (Figure 4-36, View B)

will permit movement and a wedging action with

subsequent layers. Wedging action will cause crushing

and abrasion of wire rope.

Never allow wire rope to “cross wind” on drums.

FIGURE 4-36

P448

First Wrap Tight Against

Flange for 3/4 of Diameter.

Wraps of First Layer Tight Against

Drum and Against Each Other

Wedge

Voids and Loose Wraps in First Layer

Cause Severe Wear of Wire Rope.

P449

View A

View B

WARNING

Falling Load Hazard!

• Inspect all parts prior to use. Do not use parts that are

cracked or otherwise defective.

• Remove minor nicks, burrs, or rough edges from

socket, wedge, or pin by lightly grinding. Do not

reduce original dimensions by more than 10%.

• Do not reinstall shipping material (bolt, plastic strap or

wire) in hole of wedge or socket after assembling.

Discard these materials because they can prevent

wedge from tightening in socket.

• Only use a wedge and socket which are correct size

for wire rope being used. Do not mix and match parts

from one assembly with parts from another assembly.

• Terminator™ socket and wedge has “go” and “no-go”

holes to check for proper rope size.

• Attach wire rope clip to dead end of wire rope after

assembling wire rope to wedge and socket.

• If dead end of wire rope is welded, seize end of wire

rope and cut off weld before assembling to wedge

and socket. Weld will not allow strands of wire rope to

adjust around bend of wedge, resulting in high

strands and wavy rope. This condition can seriously

weaken attachment.

Loading...

Loading...