8-21

RT765E-2 SERVICE MANUAL UNDERCARRIAGE

Published 9-04-2014, Control # 422-08

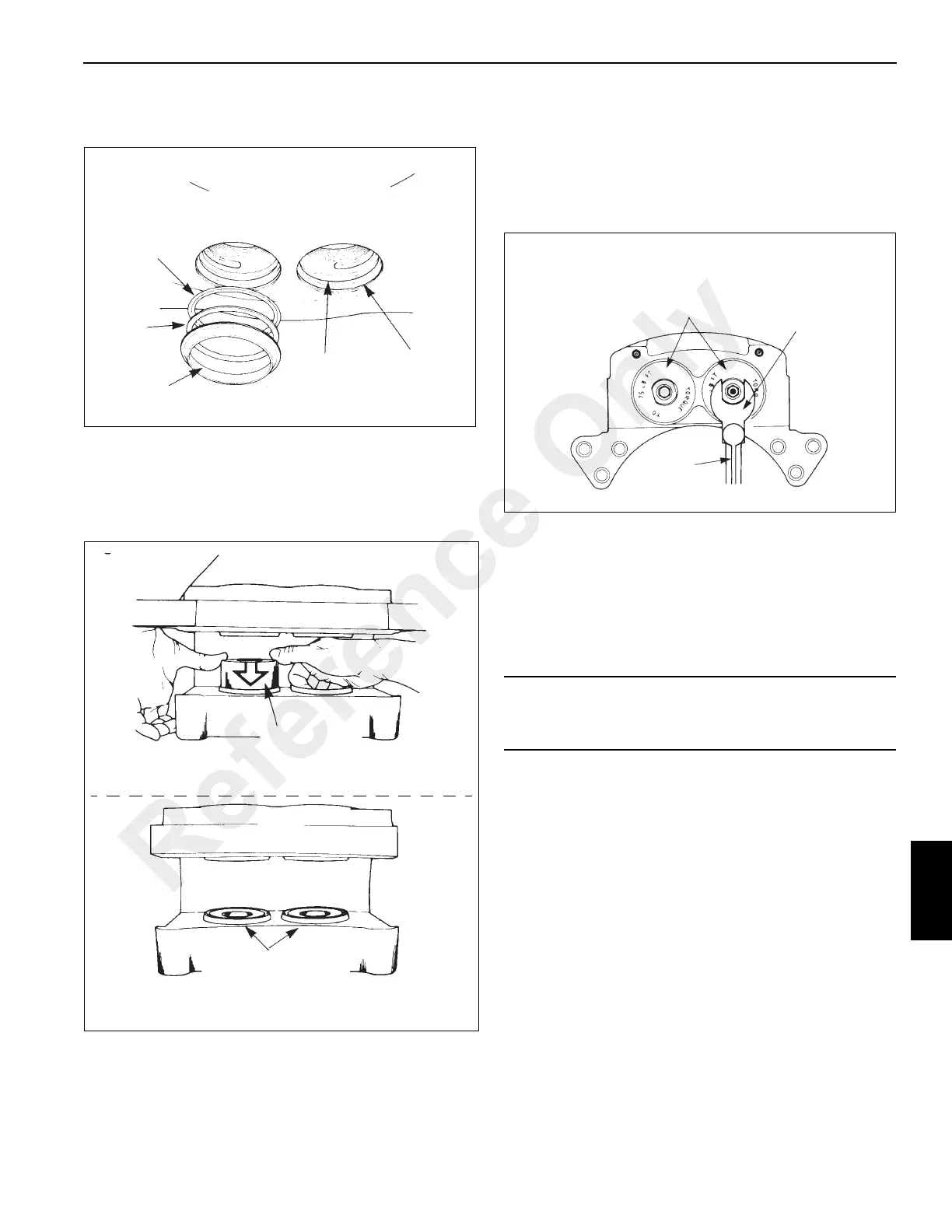

3. Install a new dust seal in the top groove of the bore.

Refer to Figure 8-24.

4. Install the pistons in the housing. Push the pistons in

from the lining side of the housing. Ensure the pistons

are straight in the bores. Push each piston into the bore

until the top of the piston is even with the top of the dust

seal. Refer to Figure 8-25.

5. Install a new O-ring in the groove of the cylinder cap.

Ensure the O-ring is not cut by the threads on the

cylinder cap.

NOTE: Apply extra grease on O-ring before installing

cylinder caps. this will keep O-ring from catching on

threads as cylinder cap is threaded into housing.

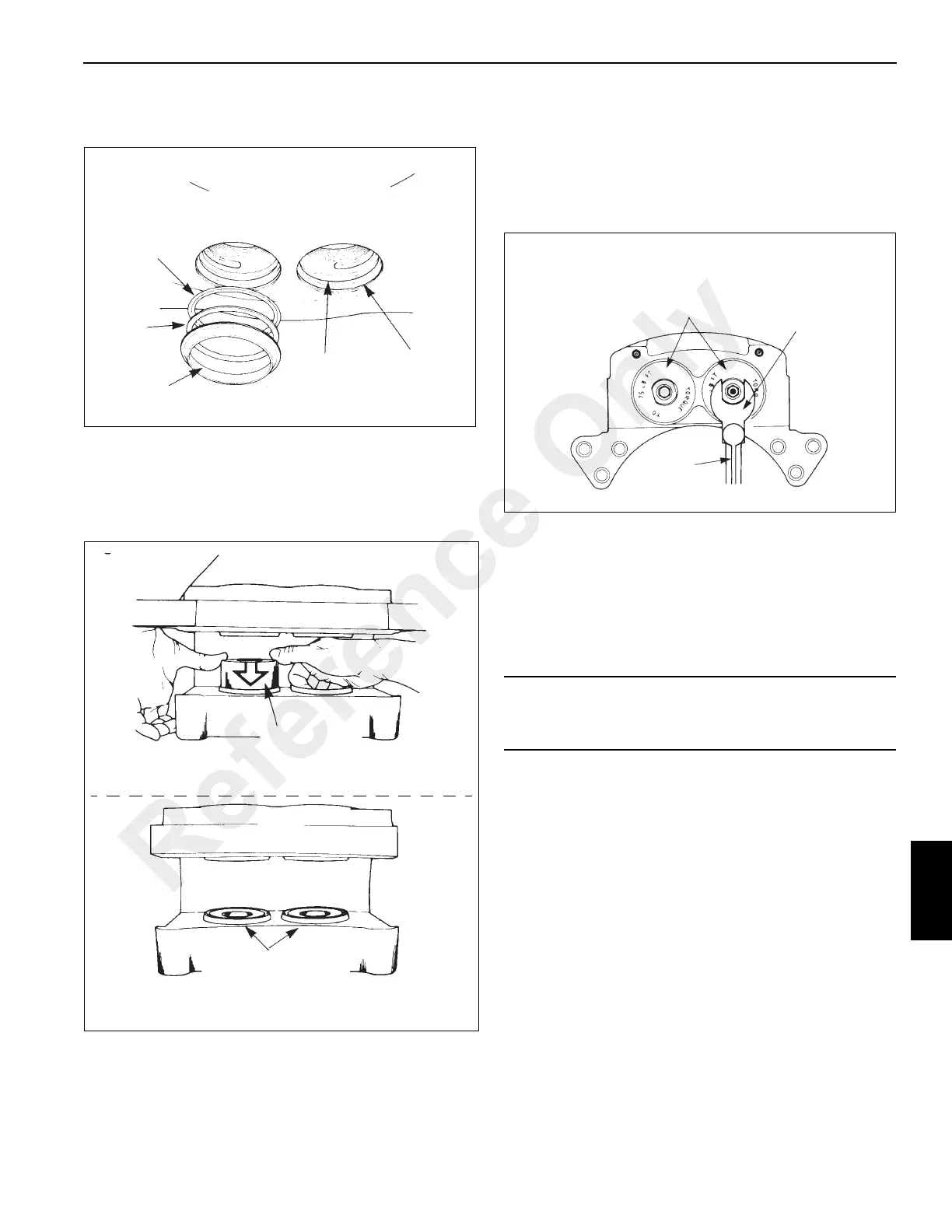

6. Install the cylinder caps in the caliper housing. Tighten

the cylinder caps to 75 lb-ft (102 Nm) minimum as shown

in Figure 8-26.

7. Install the bleeder screws in the housing. Tighten to 100

to 120 lb-in (11.3 to 13.6 Nm).

8. Install the O-ring and the inlet fitting in the cylinder cap.

Installation

Linings

1. Block the wheels.

2. Install the linings in the caliper housing.

3. Apply Loctite 271 or equivalent to the bolt threads.

Position the end plates on the housing and secure with

bolts. Tighten the bolts to 165 to 210 lb-ft (224 to

285 Nm).

4. Ensure the linings move freely in the housing.

5. Bleed the brake system.

6. Apply and release the brakes three times to ensure the

caliper operates correctly. Check for fluid leaks. Ensure

the linings move freely.

Backup Ring

and O-Ring

Groove

Dust Seal

Groove

Backup Ring -

Install Toward Lining

Side of Bore O-Ring

O-Ring

Backup

Ring

Dust Seal

O-Ring-

Install Toward

Outboard End of Bore

FIGURE 8-24

Piston - - Use

Equal Pressure to

Push Pedal into Bore

When Correctly

Installed the End of the

Piston is Even with the

Top of the Dust Seal

FIGURE 8-25

CAUTION

Always replace both linings. If only one lining is replaced,

possible disc damage can occur.

Torque

Wrench

Cylinder Cap - -

Tighten to 100 Nm

(75 ft-lb) Minimum

1.25 Inch

Crow’s Foot

Wrench

FIGURE 8-26

Reference Only

Loading...

Loading...