SWING SYSTEM RT880E SERVICE MANUAL

6-8 Published 11-10-2014, Control # 524-00

Checking the Oil Level

1. Check the level on the dipstick on the swing gearbox.

2. If no oil is visible on the dipstick, add SSGL-5 weight oil

until the level is between min and max on the dipstick.

3. Replace the dipstick in the brake housing.

Testing

1. Test swing of superstructure in each direction. Stop and

start swing several times.

2. Inspect for hydraulic leaks and repair as necessary.

SWING BEARING

Description

The swing bearing is an anti-friction roller bearing that mates

the Superstructure to the Carrier. The bearing inner race is

bolted to the Superstructure and the outer race is bolted to

the Carrier. The inner race contains two grease fittings for

lubrication of the bearing which are hosed to two fittings at

the front right side of the turntable center section.

Maintenance

General

The swing bearing is the most critical maintenance point of

the crane. It is here, at the centerline of rotation, that

stresses of loads are concentrated. In addition, the bearing

provides the only attachment between the superstructure

and carrier. Therefore, proper care of the bearing and

periodic maintenance of the turntable-to-bearing attach bolts

-IS A MUST -to ensure safe and efficient operation.

Torquing Turntable Bolts

General

Maintaining proper torque value for bolts is extremely

important for structural strength, performance, and reliability

of the crane. Variations in torque can cause distortion,

binding, or complete separation of the superstructure from

the carrier. Refer to Fasteners and Torque Values, page 1-15

for information on the use of a torque wrench and torque

values or fasteners.

Proper identification of bolt grade is important. When marked

as a high strength bolt (grade 8 and metric grade 10.9), the

serviceman must be aware of bolt classifications and that he

is installing a high strength heat-treated tempered

component and the bolt must be installed according to

specifications. Special attention should be given to the

existence of lubricant and plating that will cause variation

from dry torque values. When a high strength bolt is

removed, or un-torqued, the bolt must be replaced with a

new bolt of the same classification.

If it is reported by the crane operator or suspected that the

crane has been overloaded beyond the capacities specified

above the bold line on the cranes’ capacity chart, then all

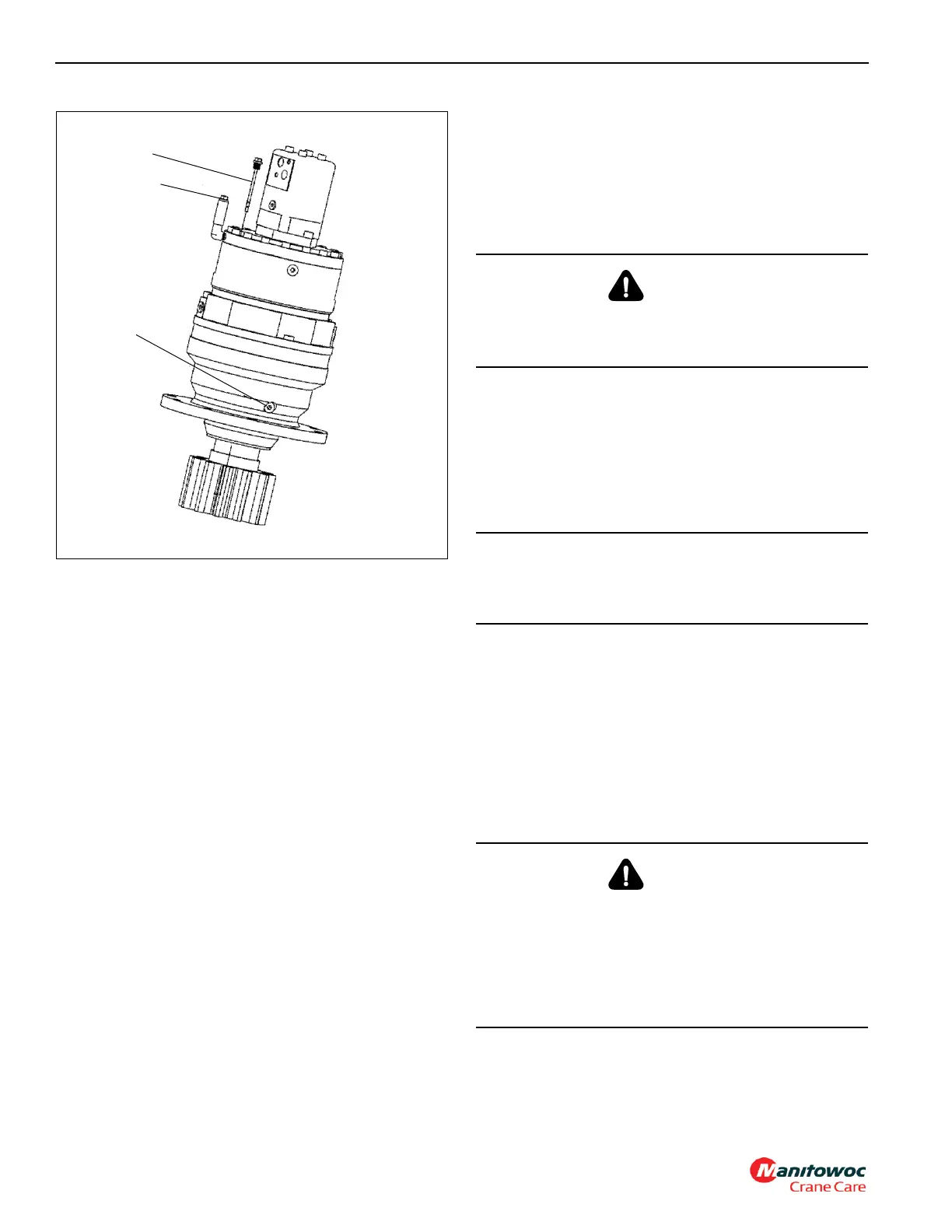

FIGURE 6-2

Dipstick Oil

Level

Breather Oil

Fill

Oil Drain

DANGER

Failure to maintain proper torque of the turntable bearing

attaching bolts will result in damage to the crane and

possible injury to personnel.

CAUTION

Repeated re-torquing may cause bolts to stretch. If bolts

keep working loose, they must be replaced with new bolts

of the proper grade and size.

DANGER

It is mandatory that bearing attaching bolts be inspected

for lack of torque and retorqued, as required, after the first

300 hours of crane operation. The bolts may loosen in

service due to vibration, shock-loads, and temperature

changes, therefore, periodic inspection should be

accomplished every 500 hours thereafter, ensuring the

bolts are properly torqued.

Loading...

Loading...