Grove Published 11-10-2014, Control # 524-00 1-15

RT880E SERVICE MANUAL INTRODUCTION

Equipment should be periodically inspected for evidence of

weld fatigue. The frequency of these inspections should be

commensurate with the age of the equipment, the severity of

the application, and the experience of the operators and

maintenance personnel.The following are known high stress

areas applicable to Grove machines, and a visual inspection

of these areas should be made part of an owner’s planned

preventive maintenance program:

• Power Telescope Boom - wear pad retaining structures,

hydraulic cylinder attaching points, boom pivot shaft

retaining structures.

• Outrigger pads, beams, boxes and attachment

structures.

• Main frames - generally in the area of doubler plates and

cross members; at the junction of front and rear frame

members on truck cranes.

• Turntable bearing connection (where bearing is welded

to the crane superstructure or chassis).

• Counterweight support structures.

• Chassis axle and suspension mounting structures.

• Hydraulic cylinder end connections.

The above is provided only as a guide, and your inspection

plan should not be limited to the areas listed. A thorough

visual inspection of all weldments is good practice.

Anyone requiring more detailed inspection instructions and/

or repair procedures may request them by contacting the

local Manitowoc Cranes distributor.

Loctite®

Always follow the directions on the Loctite® container as not

all Loctite types are suitable for all applications.Various types

of Loctite are specified throughout the Service Manual. The

following types of Loctite brand adhesives are available from

the Parts Department of the local Manitowoc Cranes

distributor.

Application of Medium Strength Loctite

NOTE: The fastener may be re-used; the adhesive may be

re-applied over cured adhesive residue.

The following procedure covers the proper application and

curing method for medium strength Loctite adhesive/sealant

(Loctite #243) and primer (Locquic Primer T 7471). (Primer is

not required with Loctite #243, but is with Loctite #242.)

Primer Application

NOTE: It is not necessary to bathe the threads in primer.

1. Ensure the threaded surface, both male and female, is

clean and free of dirt and oil. Apply a light spray coating

of primer to both male and female parts to be joined to

clean and accelerate the curing process.

2. Allow the part to dry prior to adhesive/sealant applica-

tion.

Adhesive/Sealant Application

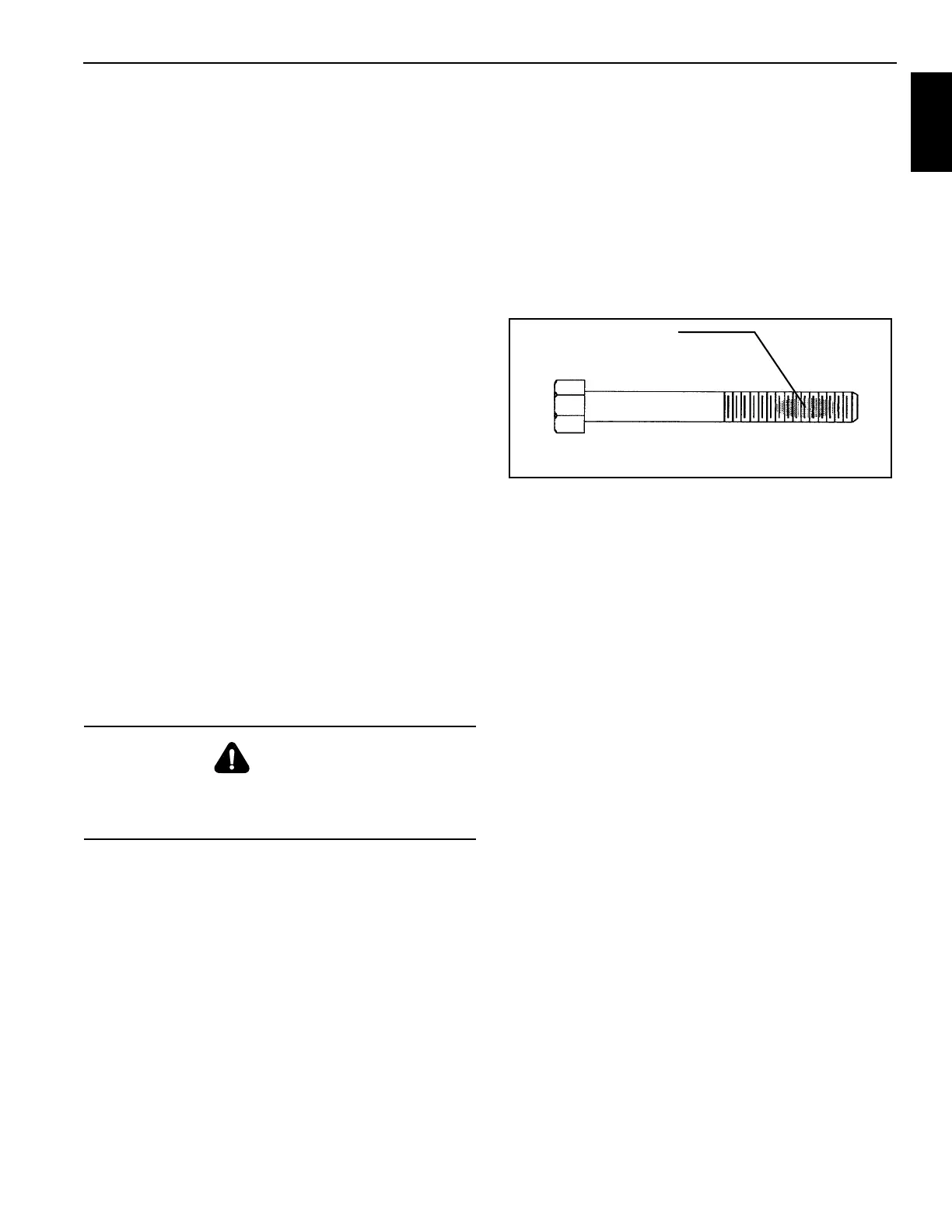

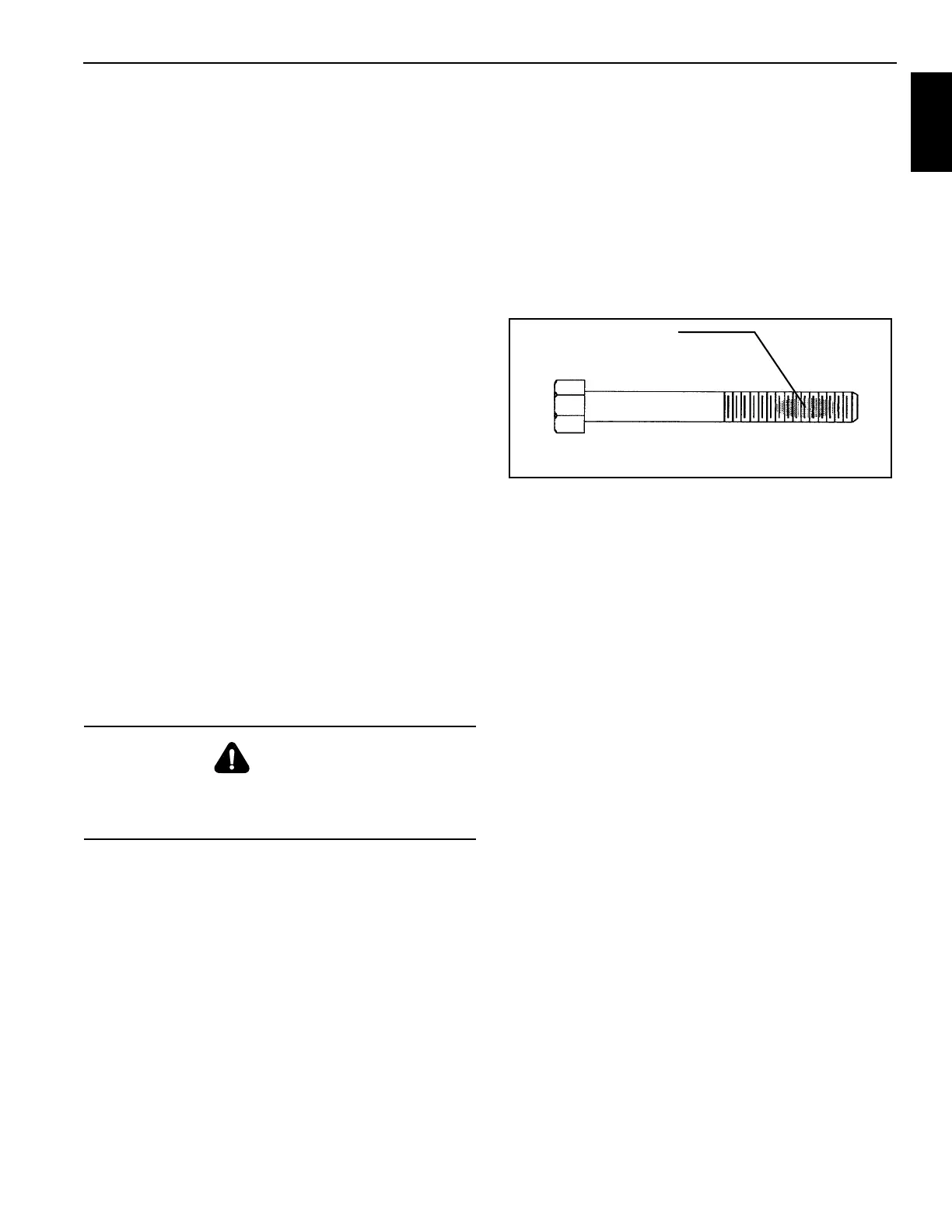

1. Apply a bead perpendicular to the thread, several

threads wide, in the approximate area of threaded

engagement (Figure 1-3).

2. In a blind hole application, a bead of several drops of

adhesive should be applied into the bottom of the hole to

be hydraulically forced up during engagement.

3. After application and engagement of mated threads,

bonding will occur within five (5) minutes if primed prior

to engagement. Fixture may take up to 30 minutes on

unprimed parts.

4. Time required to achieve full strength is 24 hours. Maxi-

mum ultimate strength is achieved using no primer with

this specific threadlocking adhesive.

Fasteners and Torque Values

Use bolts of the correct length. A bolt which is too long may

bottom before the head is tight against the part it is to hold. If

a bolt is too short, there may not be enough threads engaged

to hold the part securely. Threads can be damaged. Inspect

them and replace fasteners, as necessary.

Torque values should correspond to the type bolts, studs,

and nuts being used.

The torque tables are provided by Manitowoc for reference

when performing maintenance.

Use of proper torque values is extremely important. Improper

torquing can seriously affect performance and reliability.

Identification of fastener grade is always necessary. When

marked as a high strength bolt (grade 5, 8, etc.), the

mechanic must be aware that he/she is working with a highly

stressed component and the fastener should be torqued

accordingly.

CAUTION

Loctite® type adhesives contain chemicals that may be

harmful if misused. Read and follow the instructions on

the container.

BEAD APPLICATION

4203

FIGURE 1-8

Loading...

Loading...