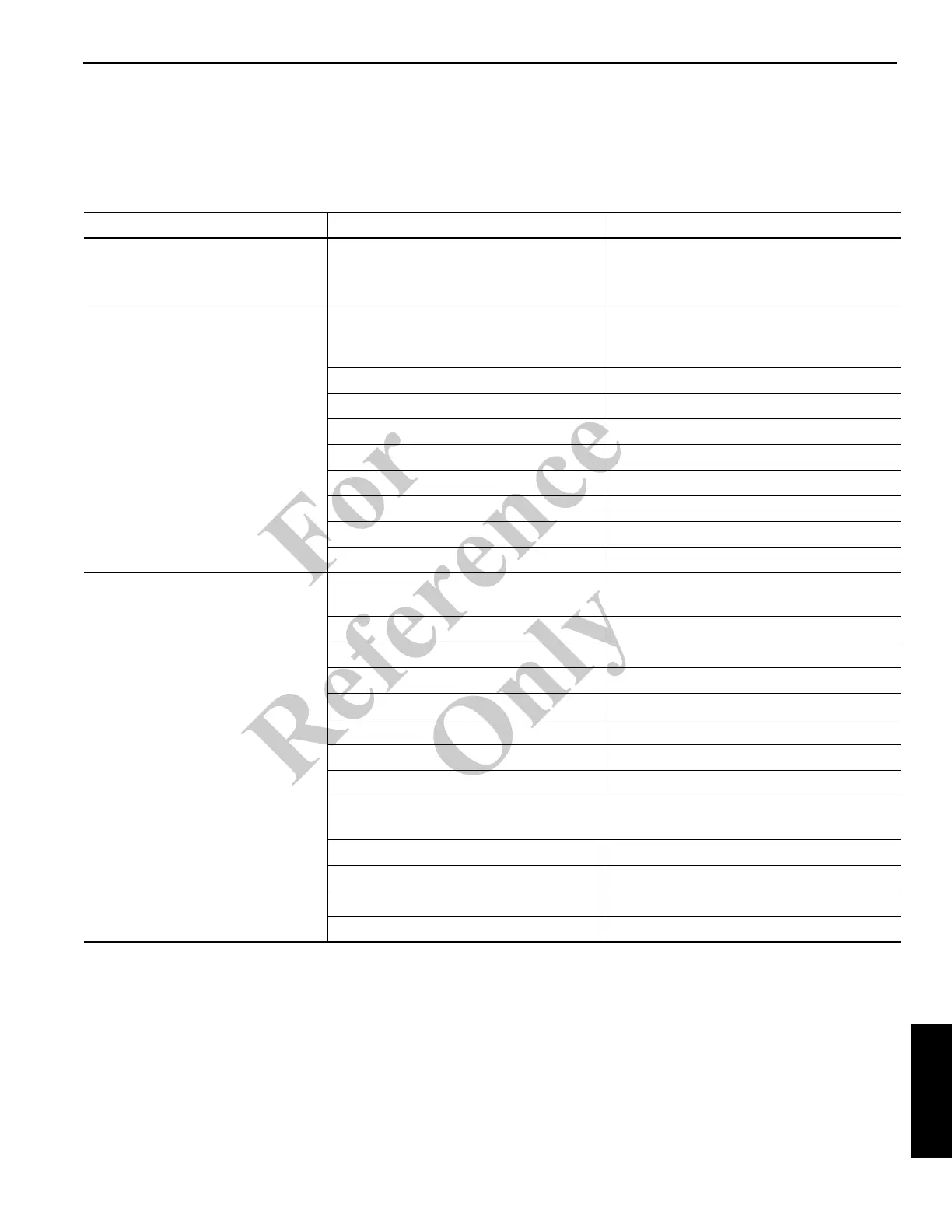

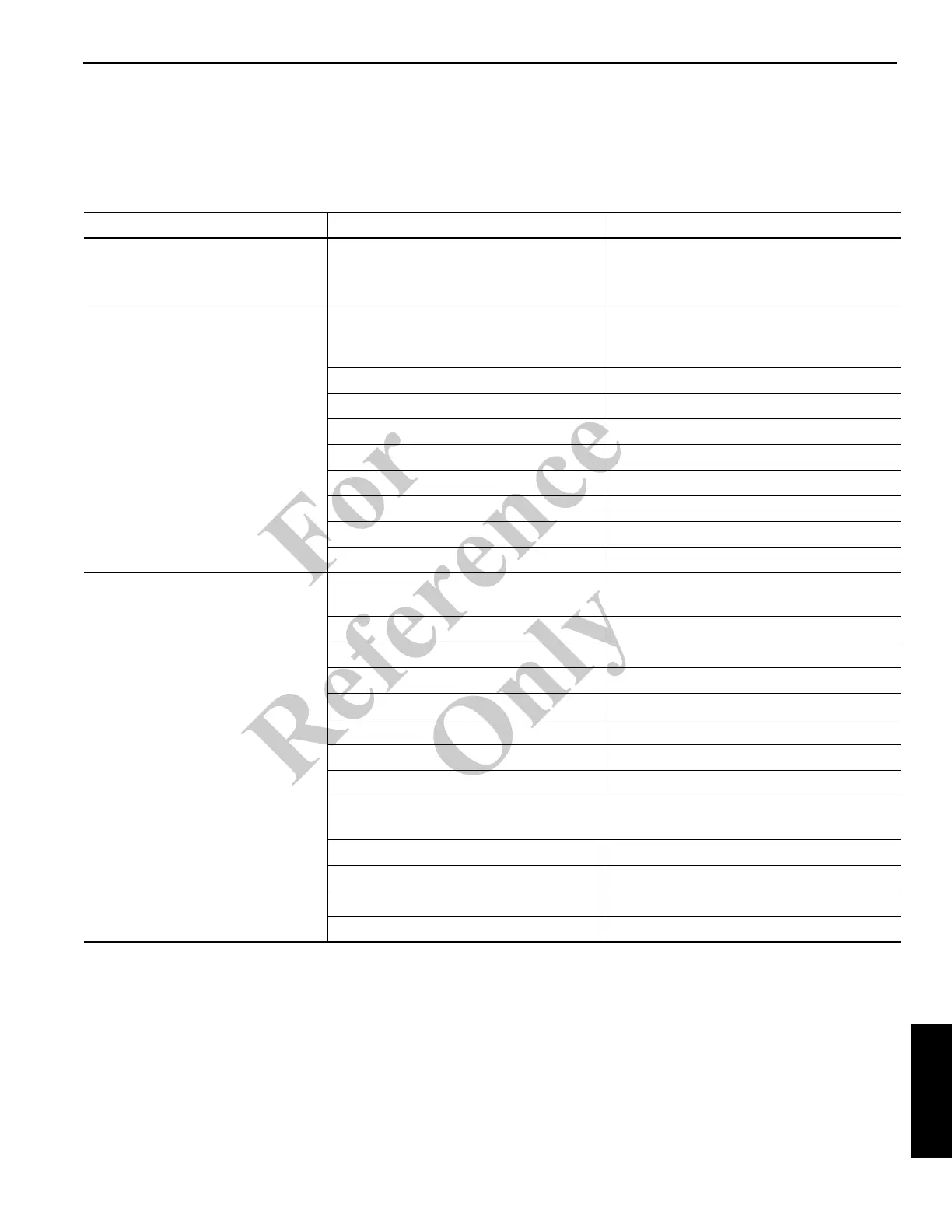

National Crane PUBLISHED 04-26-2019 CONTROL # 113-09 6-7

600E2 OPERATOR MANUAL MAINTENANCE CHECKLIST

HYDRAULIC SYSTEM TROUBLE

DIAGNOSIS

The following chart lists malfunctions which may occur

during equipment operation, followed immediately by

possible cause and possible solution. These are not all

inclusive but are designed to help isolate the problem and

should be checked before calling the factory Service

Department

Condition Possible Cause Possible Solution

Truck engine will not start

Emergency stop switch on crane control

console depressed.

Pull up emergency stop switch.

Check all other normal motor vehicle

systems as outlined by normal practice.

No response to control

Overload system inoperative.

Insure overload system is working properly

and Anti-Two-Block/Overload solenoid is

powered.

Load too heavy. Check load chart.

PTO not engaged. Engage PTO.

Low hydraulic fluid supply. Check and fill as required.

Suction line blocked. Drain tank and hose and remove blockage.

Broken hydraulic pressure line. Replace as required.

Defective hydraulic pump. See Pump Service Manual.

Incorrect relief valve setting Adjust relief.

Relief valve sticking. Clean relief.

Poor hydraulic system performance

Pump not operating at proper speed.

Check PTO ratio, pump size and engine

speed for proper oil flow.

Low hydraulic fluid supply. Check and fill as required.

Relief valve sticking. Remove and clean.

Relief setting too low. Readjust to proper setting.

Worn pump, motor or cylinder. Replace bad part.

Plugged filter. Change filter.

Valve spools not fully open. Adjust linkage so valve has full throw.

Boom holding valves out of adjustment. Adjust or clean as required.

Oil temperature too high.

Reduce engine speed, slow cycle time to

cool oil or add oil cooler option.

Hydraulic oil too cold or dirty. Warm oil or use less viscous oil.

Line restricted. Check lines; clean and repair as necessary.

Internal control valve crack. Replace valve.

Load too heavy. Check load chart and reduce load.

Fo

r

Reference

Only

Loading...

Loading...