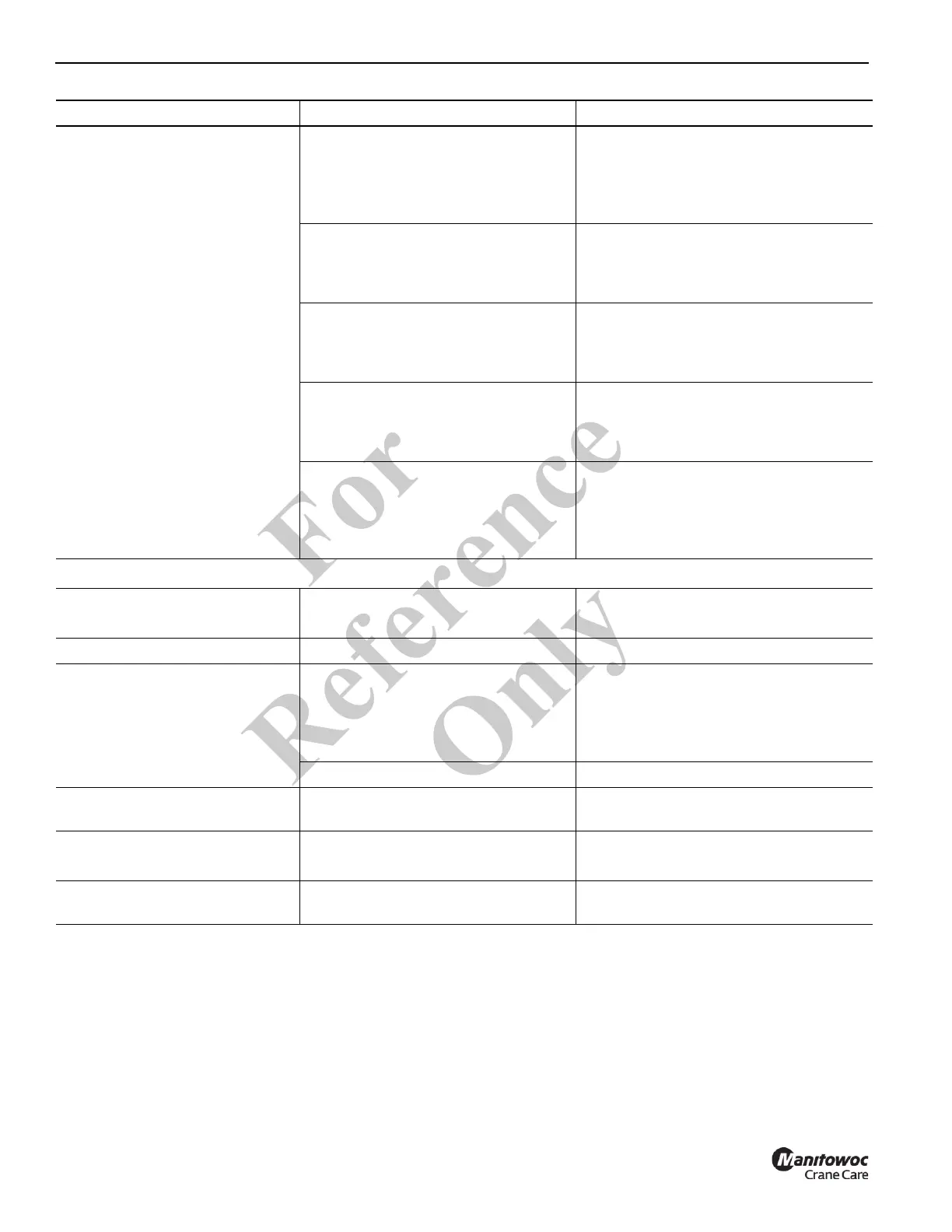

MAINTENANCE CHECKLIST OPERATOR MANUAL 600E2

6-10 PUBLISHED 04-26-2019 CONTROL # 113-09

System cuts out too early or too late

Wrong table selected.

Check to see which table is selected using

the single character display. If the wrong

table is selected, select the proper table

using the procedure in the system

installation section.

Single sensor not zeroed.

Ensure that the electronics box is tightly

mounted to the extension. Zero the angle

sensor using the procedure in the system

installation section.

Configuration switch stuck open or closed

(two section extensions only).

Configuration switch must be closed when

the extension is Retracted and open when

the extension is extended. Adjust or replace

switch As necessary.

Pivot pin not free to move.

Ensure that pivot pin is free, well lubricated,

and allows the extension head to pivot freely.

Inspect and replace bearings in extension

head assembly as required.

Foreign object stuck between extension

head assembly and extension. The only

contacts between the extension head

assembly and the extension are to be the

load cell and the pivot pin.

Remove any foreign objects which interfere

with extension head assembly operation.

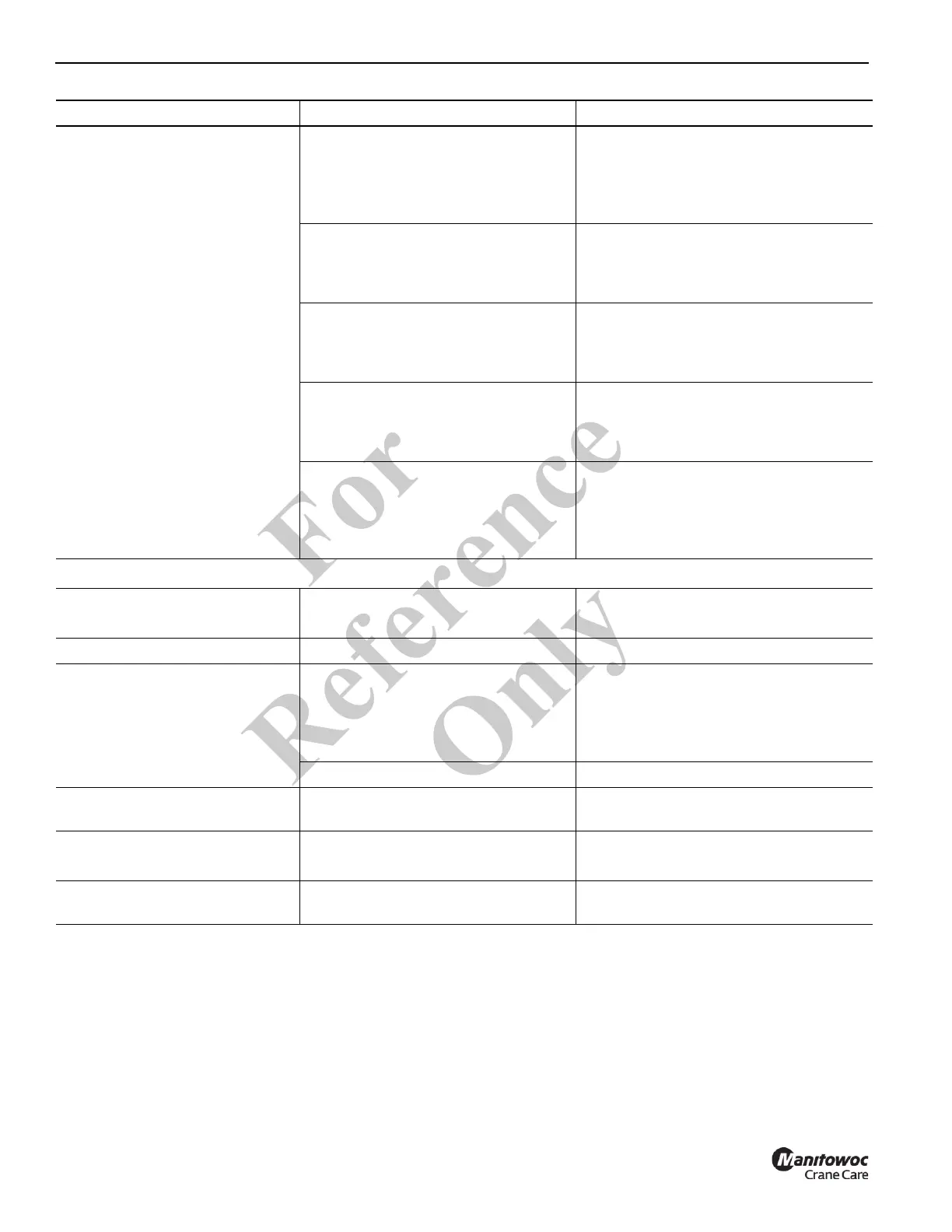

Extension Jack Troubleshooting

Will not lift load

No oil in system

Release valve not closed

Add oil to reservoir tank through oil filler hole

Turn handle clockwise tightly

Will lift load only part way Oil level low Add oil to reservoir tank through oil filler hole

Will lift load but will not hold

The following valve or valves leaking

• Suction valve

• Delivery valve

• Release valve

Replace jack

Packings worn or damaged Replace jack

Jack will not lower

Release valve stuck, probably dirt or

foreign matter

Transfer load then replace dirty oil, flush oil

reservoir with kerosene

Poor lifting

Dirty oil

Air in hydraulic system

Change hydraulic oil

Purge air from system

Poor pumping action

Oil seal for pump unit worn in out or

damaged

Replace jack

Condition Possible Cause Possible Solution

Fo

r

Reference

Only

Loading...

Loading...