National Crane PUBLISHED 04-26-2019 CONTROL # 113-09 4-11

600E2 OPERATOR MANUAL SET-UP

14. Using hoist function, unspool enough loadline to reeve

loadline over extension sheave case. Keep slight

tension on loadline to avoid bird caging of loadline on

hoist drum.

15. Route loadline over extension sheave and install keeper.

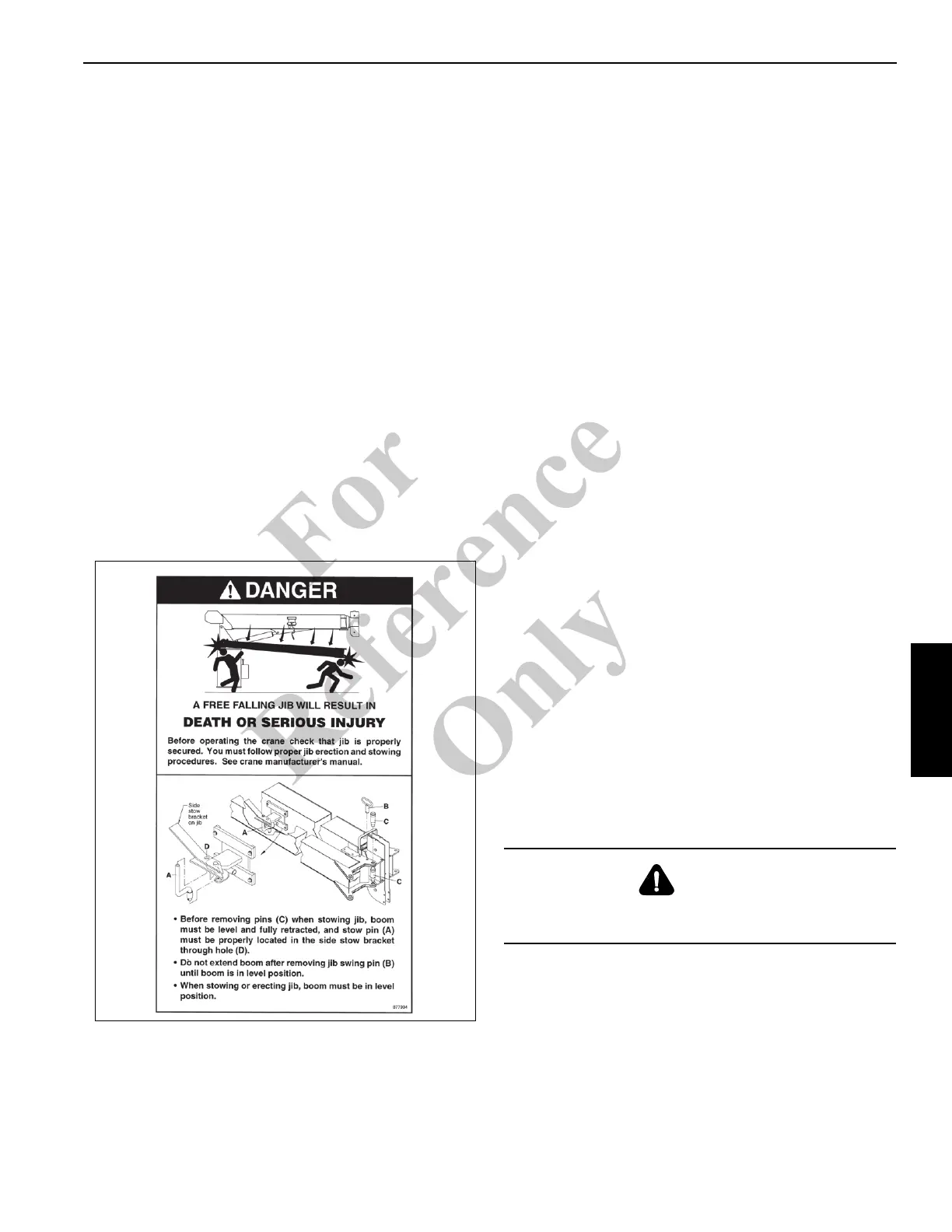

Install line block to end of loadline.

16. Remove anti-two-block weight/chain assembly from

boom tip switch and install on extension tip switch. Be

certain to use keeper provided with switch.

17. Disconnect twist lock quick coupler on anti-two-block

cord going to boom anti-two-block switch and attach to

quick coupler on extension anti-two-block wire on rear of

extension between the upper and lower extension ears.

18. Install extension swing pin B and spring clip into

extension ears.

19. For manually extendable extensions, pull extension

retention pin E, and extend second section out by pulling

on sheave case. The second section extension, as it

extends, will hit a mechanical stop that allows for

extension pin E installation. Install pin E and spring clip.

STOWING PROCEDURE

1. Using lift function, lower boom so that extension tip is

close to the ground.

NOTE: When lowering the boom below horizontal, two

persons may be required. With the telescope

control in neutral, the boom can creep out when

below horizontal.

2. For manually extendable extensions, pull extension

retention pin and fully retract extendable 2

nd

section

extension into the 1

st

section. Retraction of 2

nd

section

may be facilitated by attaching loadline wedge socket to

attachment point F on the extension sheave case.

Slowly activate the hoist up function until the 2

nd

sections fully retracted

3. Reinstall extension retention pin through the 1

st

and 2

nd

section extension assembly and install spring clip.

4. Remove loadline from extension sheave case. Place

loadline in area to avoid possible damage from stow

procedure.

5. Disconnect twist lock anti-two-block wire connector at

rear of 1

st

section extension. Connect twist lock

connector to anti-two-block switch connector on boom

tip. Move anti-two-block weight assembly to boom tip

switch.

6. Attach tag line to sheave case end of extension.

7. Remove spring clips from pins C2 on both upper and

lower extension ears.

8. Remove pins C2 from upper and lower extension ears.

Do not remove C1 pins at this time. C1 pins will be used

as a pivot point to swing extension into stow position. A

slight hammer strike may be necessary to remove pins.

Always use proper eye protection during this step.

Utilization of the extension jack at this time will aid in pin

hole alignment to facilitate pin removal.

9. Using lift function, raise boom to a horizontal position.

10. Using extend function, extend boom approximately 1

foot.

11. Using tag line attached to extension sheave case, slowly

swing extension into stow position (parallel with 1

st

section boom). Pins C1 are the extension pivot points

during this operation.

12. Install extension swing pin B with spring clip through

extension ear and boom sheave case holes. This pin will

keep the extension assembly in line (parallel) with the 1

st

section boom. Pin B does not retain the extension in its

stowed position on the 1

st

section boom.

13. Using boom telescope function, slowly retract boom.

The ramp/side stow bracket assembly on the side of the

1

st

section extension will engage the hook on the side of

CAUTION

Use caution when swinging extension to avoid

unnecessary impact with 1st section boom

Fo

r

Reference

Only

Loading...

Loading...