11

CHAPTER 3

To utilize the strain relief fitting, insert the signal, data,

and AC connections into each loudspeaker as the array is

being rigged (swag all cables under the rain hood’s sides if

installed), and tie the cables off to the ring/stud fitting, as

shown in Figure 3.3.

R

E

-

C

I

R

K

-

I

T

P

U

S

H

R

E

-

C

I

R

K

-

I

T

P

U

S

H

10

10

!

RIS KO FE LEC TRIC S HOCK

DO NOT OPEN

CAU TION

95-125V~

50-60Hz

2000WRMS MAX

OperationalV olta geRang e:

Turnon 85V ~ Turnoff 134V ~

Turnon 165V ~ Turnoff 264V ~

208-235V~

50-60Hz

2000WRMS MAX

Auto-Volta geSelect

ATE NCI ÓN: AC CES O INTE RN O SOL O

AUTO RIZA DO A PER SON AL TÉC NICO C ALIF ICAD O

ACH TUNG: G EHÄUS E NICH TÖ FFNE NW ARTU NG

UND REPAR ATUR NUR DUR CHE LEK TROFAC HKRÄ FTE

ATT ENT ION: E NTR ETI EN ET R EPA RAT IONS

INTE RN ES NE S ONT A UTOR ISE ES Q U'AU

PE RSO NNE L TEC HNIQ UE QUA LIF IÉ

UK WA RNI NG:

THIS APPA RAT US MUS T BE E ART HED .

NOOPERA TORSER VICEABLEP AR TSINSIDE.

REFERSER VICINGT O QUALIFIED PERSONNEL

WAR NING S:

THIS PRO DUCT M UST B E GR OUNDE D.

Thissurface ma yreac hhigh temperatureswhilein use .

Toensure pr operoperation, allo watleast 6inc hes

clearancefr omthissurface andadequateventilation.

Nooperator ser viceab lepar ts inside .

Refer ser vicingtoqualified per sonnel.

Toreduce theriskof fireor electricshoc k

donot expose thisapplianceto rainor moisture .

Act ive

Low Ch Lim it

Hig hC hL imit

MI CA

2+

Earth /Chassis

1

Case

220K Ω

ESD

3-

10K Ω

Balanced

1

2

3

1

3

2

Loop

Input

Netw ork

S

e

r

v

i

c

e

W

i

nk

R

e

s

e

t

A

c

ti

v

i

t

y

Re mote Mon itor S yst em

Me ye r So und , Be rk el ey, C A. US A

PUSH

Cable Tie-Off Point

Figure 3.3. Cables are easily tied off using the rear ring/stud fitting.

CAUTION: The strain relief ring and stud

fitting must be used only to secure system

cabling. This fitting is not intended to be used with

system rigging or a pull-back motor (pulling the

bottom of the array backward to increase downward

tilt). The strain relief fitting is mounted to the side of

the amplifier area so as not to interfere with the rain

hood (if fitted) and the amplifier fan exhaust area.

THE TRUPOWER LIMITING SYSTEM

Conventional limiters assume a constant loudspeaker

impedance and therefore set the limiting threshold by

measuring voltage only. However, this method is inaccurate

because the loudspeaker’s impedance varies throughout

its frequency range, changing in response to the frequency

content of the audio source. In addition, the impedance also

changes due to temperature variations in the voice coil and

magnet. Consequently, conventional limiters begin limiting

prematurely, which under-utilizes system headroom and

lessens the loudspeaker’s dynamic range.

In contrast, TruPower limiting (TPL) accounts for varying

loudspeaker impedance by measuring current as well as

voltage to compute the actual power dissipation in the

voice coil. TPL improves performance before and during

limiting by allowing each driver to produce maximum SPL

across its entire frequency range.

NOTE: TPL only reduces the signal level

to keep the voice coil below its maximum

operating temperature, hence the peaks are

unaffected.

In addition, TPL eliminates power compression when the

system is operated at high levels for extended periods, and

also extends the driver life cycle by controlling voice coil

temperatures.

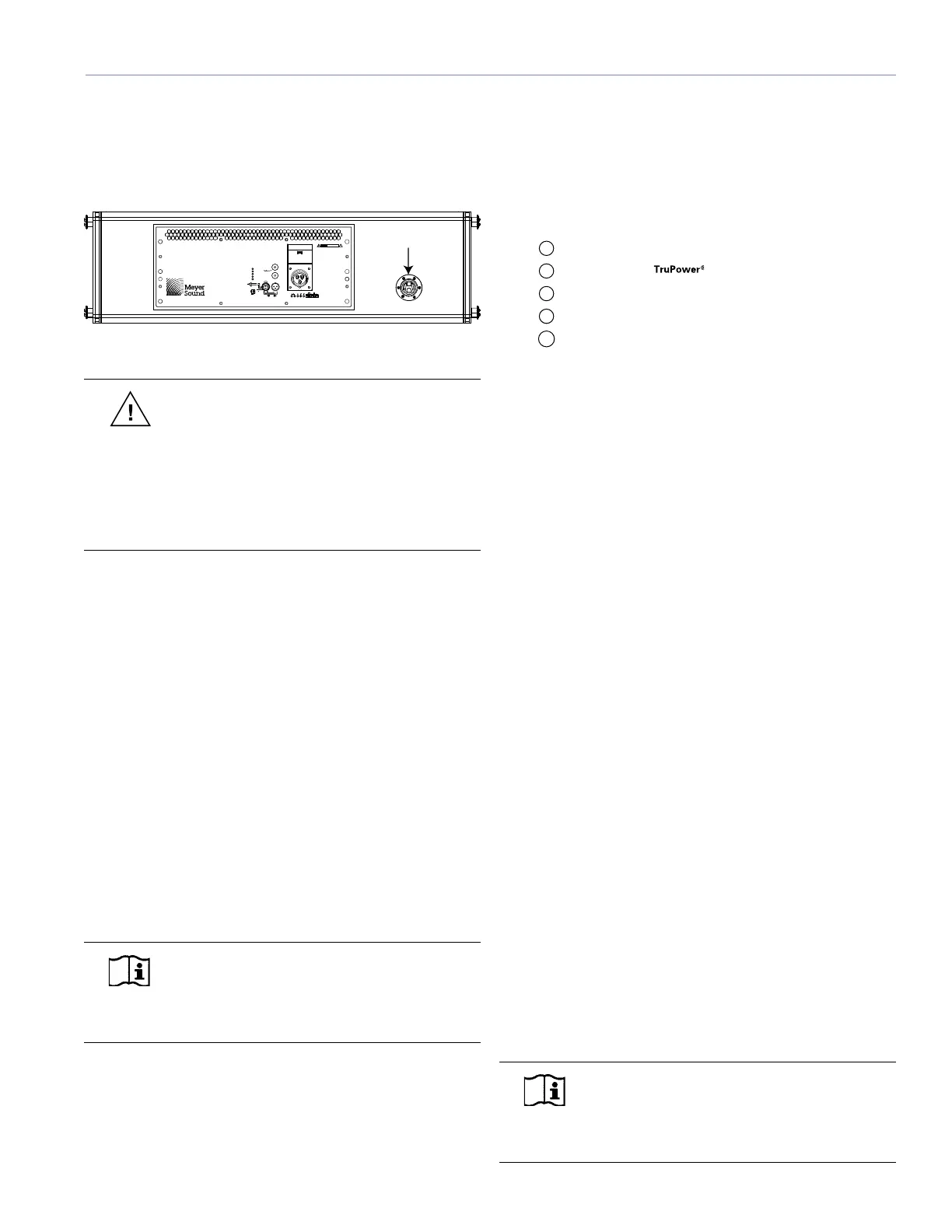

The actual power is monitored for all four of MICA’s

amplifier channels. When the safe continuous power level is

exceeded, the TPL limiter controlling that amplifier channel

engages. TPL activity is indicated by the LEDs on the user

panel (Figure 3.4).

Active

Low Ch Limit

High Ch Lim it

MICA

2 +

Earth / Chassis

1

Case

220K �

ESD

3 -

10K

�

Balanced

1

2

3

1

3

2

Loop

Input

Network

S

e

r

v

i

c

e

W

i

n

k

R

e

s

e

t

A

c

t

i

v

i

t

y

Remote Monitor System

PUSH

Figure 3.4. MICA Limit LEDs

Low- and Mid-Frequency Limiters

MICA’s left and right 10-inch cone drivers are powered by

separate amplifier channels, each with a power detector

but routed to one limiter; the limiter tracks both channels

and uses the higher of the two values to engage. By limiting

both amplifier channels equally, any anomalies in the

frequency range shared by the drivers are eliminated during

limiting. The Low Ch Limit LED on the user panel indicates

TPL activity for these two drivers. When the power level and

voltage for both low channels returns to normal — below

the limiter’s threshold — the limiter will cease operation.

High-Frequency Limiter

The two 3-inch diaphragm high-frequency compression

drivers are also powered by two amplifier channels

receiving identical audio signals; these channels have both

TPL and peak limiters. The limiter tracks both channels and

uses the higher of the two values to engage. By limiting

both amplifier channels equally, any anomalies in the

frequency range shared by the drivers are eliminated during

limiting.

The High Ch Limit LED is used to indicate any limiting

activity for these drivers. When the LED turns on and off in

rapid succession, it indicates peak limiting; when it turns on

and off slowly, it indicates TPL activity. When engaged, the

peak limiter prevents signal peaks from causing excessive

distortion in the amplifier channel, preserving headroom

and maintaining smooth frequency response at high levels.

When the power level and voltage for both high channels

returns to normal — below the limiter’s threshold — the

limiter will cease operation.

NOTE: The limiting circuitry utilizes optical

limiters that add no noise and have no effect

on the signal when the limiter is not engaged and

the LED is inactive.

Loading...

Loading...