Is the toll set surely?

If the toll has not been set surely, the tool may float and it may cause being

patchy or the part not to be cut.

Is the protruding

amount of the blade

edge proper?

If it is too much or too less, adjust it to the proper amount. (Use the value of

sheet thickness +0.3mm as a reference.)

Isn’t the blade edge

damaged or worn

away?

If the blade edge is damaged or worn away, even if you increase the cutting

pressure (PRESS), the cut surface fuzzes and you cannot cut beautifully.

In such a case, replace the blade edge.

For the replacing method, refer to the Operation manual chapter 2 “How

to install a cutter”.

Is the proper cutting

condition set?

It is necessary to change the cutting condition depending on the sheet to

use.

By referring to the Operation manual chapter 2 “Set the Tool Condi-

tions”, set the cutting condition suitable for the sheet.

Did you set the

DUMMY CUT?

By DUMMY CUT (aligning the blade edge direction), you can improve the

cutting quality.

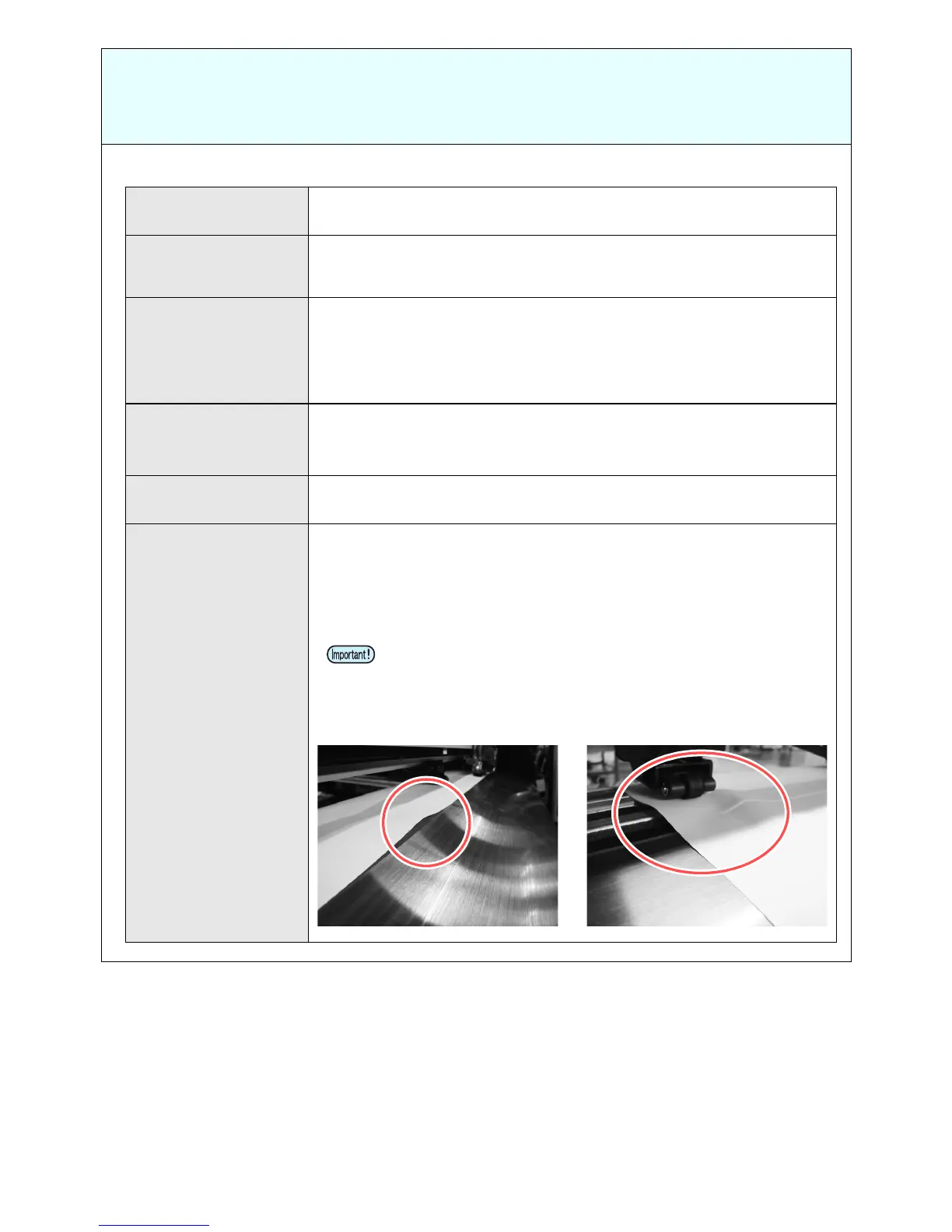

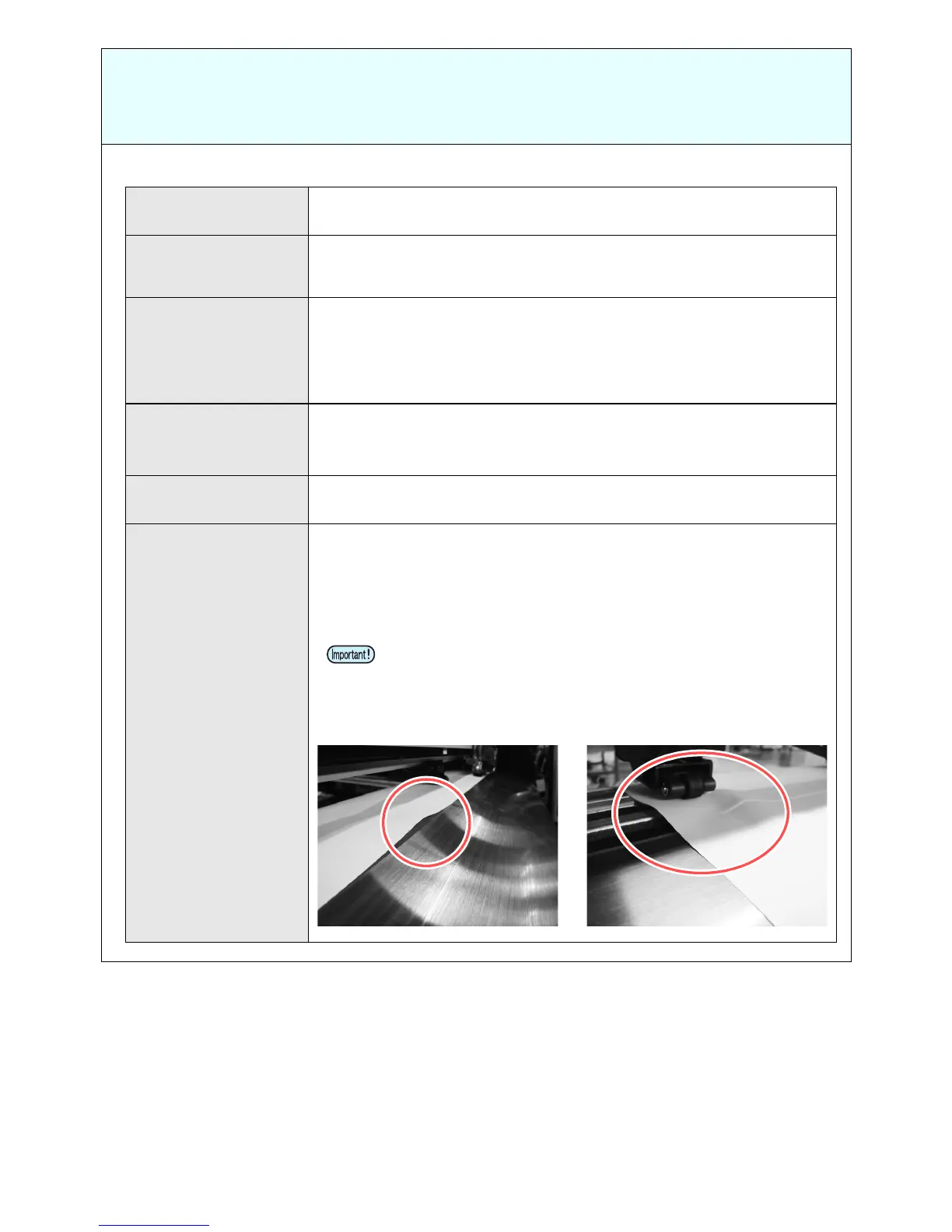

Doesn’t the sheet

float?

Due to the temperature or the humidity, the sheet may float described in the

photo.

Referring to P.5 "Prepare the place where meets conditions below:",

check whether APC-130 is used under the environment recommended by

our company.

• Especially, check the temperature and the humidity. On a rainy

day, the sheet may expand and shrink much, and it may cause

sheet misalignment.

Use it under the environment with little change in the

temperature and the humidity.

Loading...

Loading...