f

ENGINE

CYLINDER HEAD ASSEMBLY

Cylinder

head

The head, made

of

a special cast iron,

is

shaped

to

retain greater rigidity and

promote

the conduction

of

excess

heat

to the coolant.

As

will be

noted

in the cross section, the head

carries overhead valves arranged for cross-flow

intake-air admission and scavenging,

with

intake

port

located

on

the right and

exhaust

port

on

the left. The high power capability

of

the Model

K3A and K3C

is

measurably

accounted

for the

improved volumetric efficiency resulting from

this valve configuration.

The pre-chamber (pre-combustion chamber),

in which the swirl

type

of

pre-combustion takes

place,

is

of

insert type in construction, and

is

press-fitted into the cylinder head

to

form its

integral part.

The

pre-chamber

is

not

meant to

be removed from the head in engine disassembly.

The valve guides for

both

intake and exhaust

valves are common, there being no need to

distinguish between the two.

They

are

of

a

sintered alloy, impregnated with oil for increased

resistance to abrasive wear.

2-4

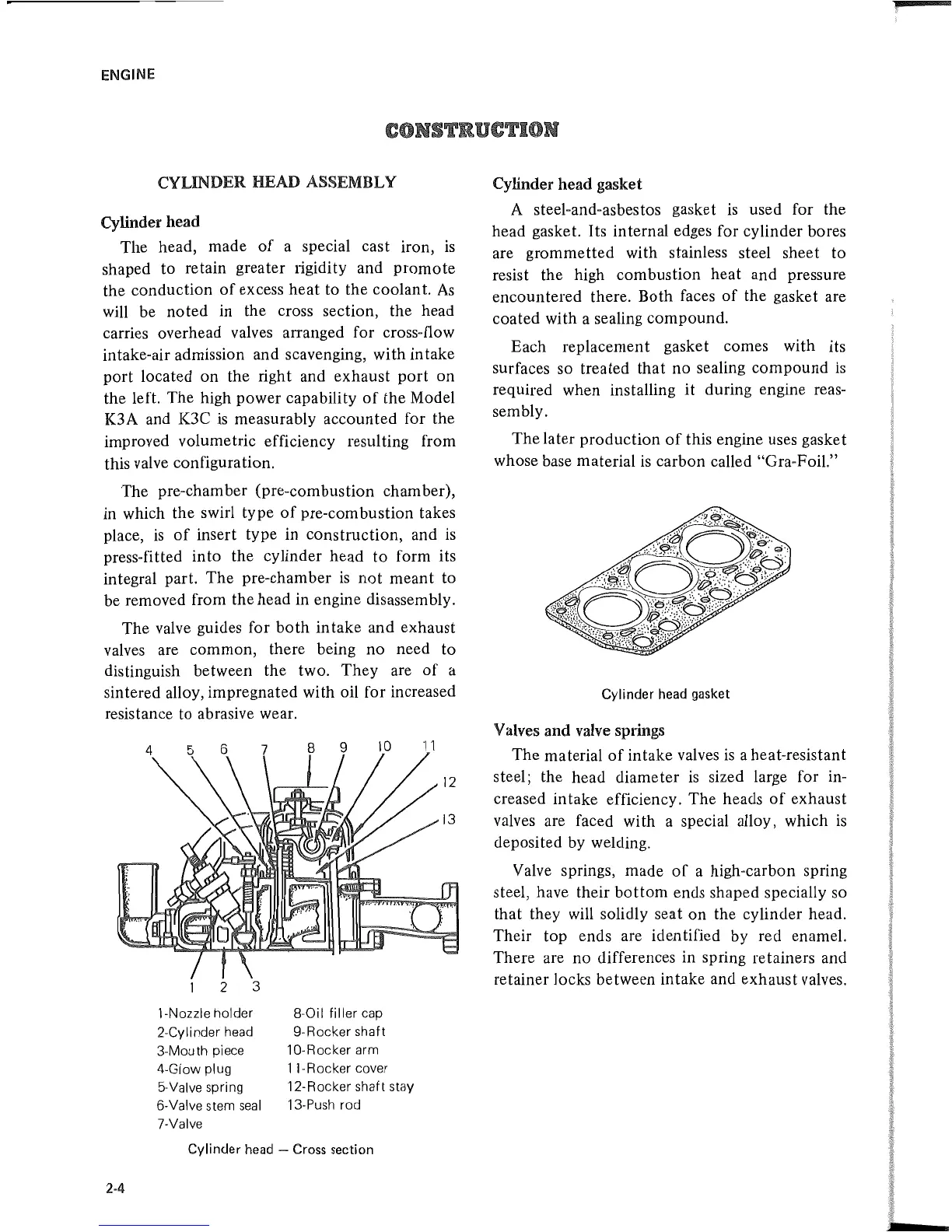

2 3

l-Nozzle holder

2-Cylinder head

3-Mouth piece

4-Glow plug

5-Valve spring

6-

Valve stem

seal

7-Valve

8-0il filler cap

9-Rocker shaft

10-Rocker arm

ll-Rocker

cover

l2-Rocker shaft stay

l3-Push rod

Cylinder head - Cross section

Cylinder head gasket

A steel-and-asbestos gasket

is

used for the

head gasket. Its internal edges for cylinder bores

are

grommetted

with stainless steel sheet to

resist the high combustion

heat

and pressure

encountered there.

Both

faces

of

the gasket are

coated with a sealing compound.

Each replacement gasket comes with its

surfaces so treated

that

no sealing

compound

is

required when installing

it

during engine reas-

sembly.

The later

production

of

this engine uses gasket

whose base material

is

carbon called "Gra-Foil."

Cylinder head gasket

Valves and valve springs

The material

of

intake valves

is

a heat-resistant

steel; the head diameter

is

sized large for in-

creased intake efficiency. The heads

of

exhaust

valves are faced with a special alloy, which

is

deposited by welding.

Valve springs, made

of

a high-carbon spring

steel, have their

bottom

ends shaped specially so

that they will solidly seat

on

the cylinder head.

Their top ends are identified by red enamel.

There are no differences in spring retainers and

retainer locks between intake and exhaust valves.

Loading...

Loading...