n

r-

1-

d

Crankshaft

Flywheel

and

ring gear

The

flywheel

is

made

of

a cast iron.

The

pilot

bearing for holding the

clutch

main

shaft

end

is

a ball bearing.

The

ring gear

is

made

of

a

carbon

steel and

shrink-fitted to

the

flywheel; its gear

teeth

are

induction-hardened.

Pistons,

piston

pins

and

piston

rings

The

piston

is

an aluminum-alloy die casting,

and possesses a minimized inertial mass so

that

the high-speed load

on

the

main

bearings

is

greatly reduced. Its

diameter

is

cam-ground and

tapered

to

optimize its fit in

the

bore when

the

block comes up

to

the

normal

operating

temper-

ature.

The

piston pin

is

a hollow forging, whose

finished surface

is

casehardened

by

carburization;

it

rotates in

the

piston

but

press-fitted

into

the

connecting rod,

thereby

presenting a semi-float-

ing

type

of

small

end

connection.

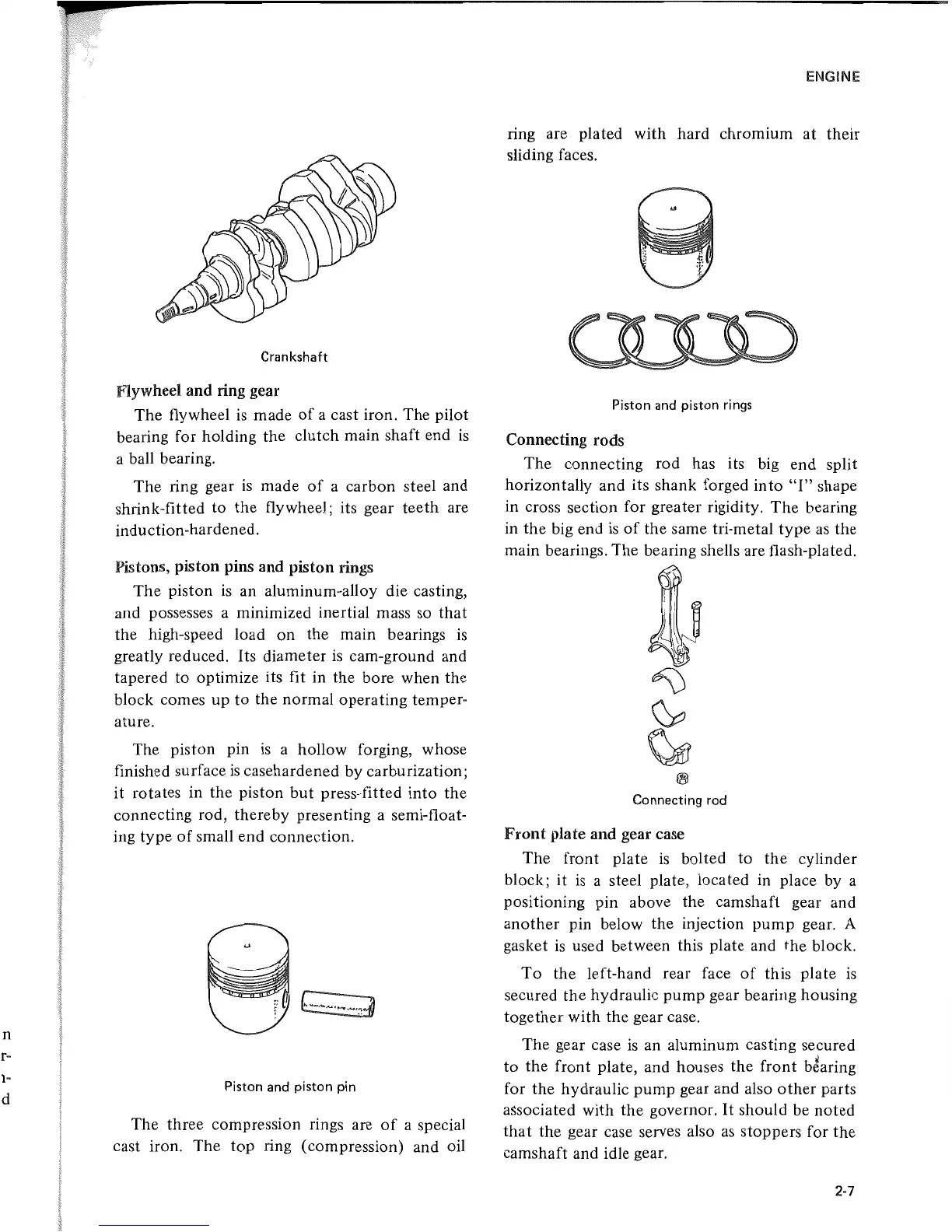

Piston

and

piston

pin

The

three compression rings are

of

a special

cast iron.

The

top

ring (compression) and oil

ENGINE

ring are plated with

hard

chromium

at

their

sliding faces.

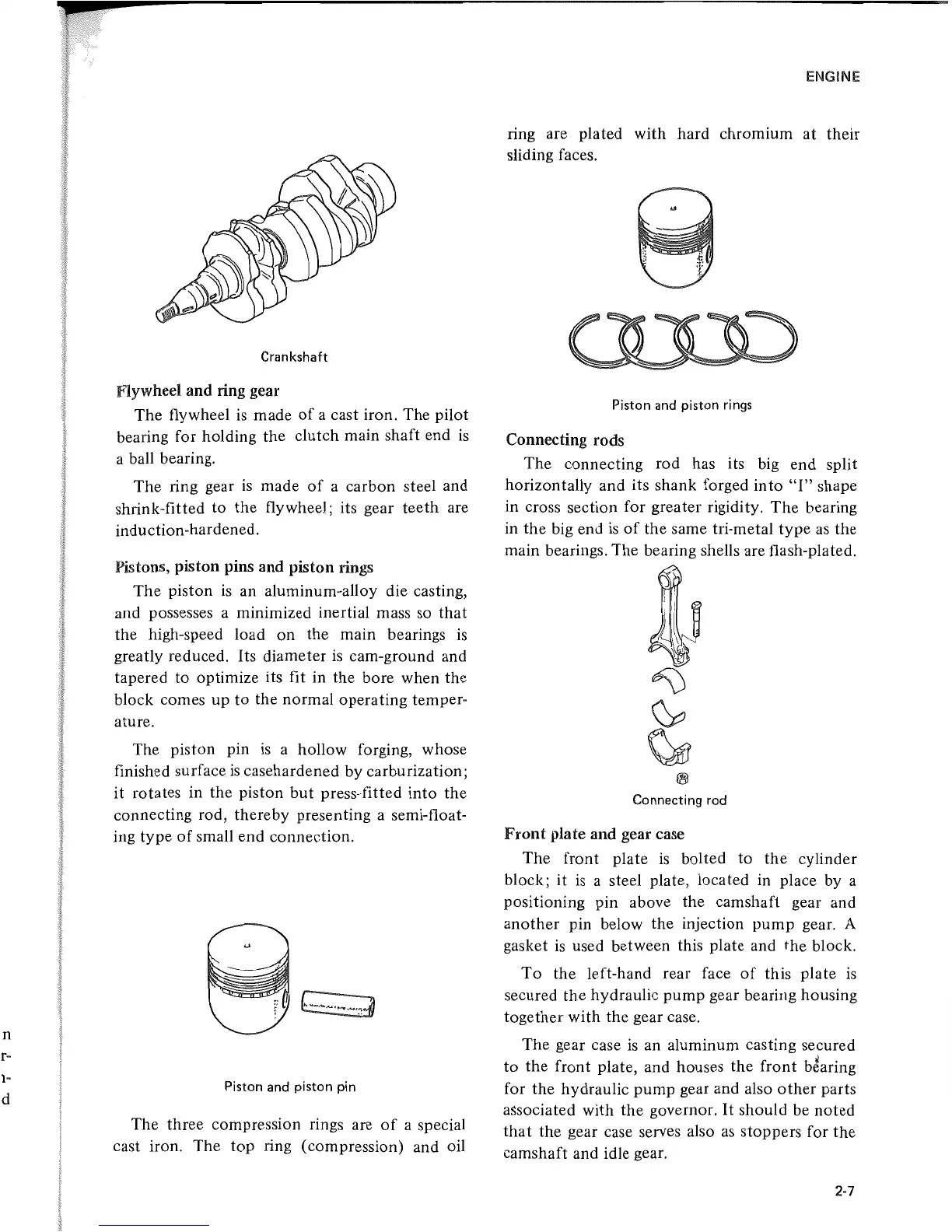

Piston

and

piston

rings

Connecting rods

The

connecting

rod

has its big end split

horizontally

and

its

shank

forged

into

"I"

shape

in cross section for greater rigidity.

The

bearing

in

the

big end

is

of

the

same tri-metal

type

as

the

main bearings.

The

bearing shells are flash-plated.

®

Connecting

rod

Front

plate

and

gear case

The

front

plate

is

bolted

to

the cylinder

block;

it

is

a steel plate, located in place by a

positioning pin above the camshaft gear

and

another

pin below

the

injection

pump

gear. A

gasket

is

used between this plate and

the

block.

To

the

left-hand rear face

of

this plate

is

secured

the

hydraulic

pump

gear bearing housing

together

with

the gear case.

The

gear case

is

an aluminum casting secured

to

the

front

plate, and houses the

front

b~aring

for

the

hydraulic

pump

gear and also

other

parts

associated

with

the

governor.

It

should

be

noted

that

the gear case serves also

as

stoppers

for

the

camshaft and idle gear.

2-7

Loading...

Loading...