s

g

11

e

g

s,

n

he

;a-

nd

he

1al

ed

led

lial

the

Main bearings

and

connecting-rod bearings

(1) Inspect

the

bearing shells, paying particular

attention

to

the

tri-metal surface for evi-

dence

of

flaking. Burnt,

pitted

or

wiped

shells and shells showing

bad

contact

pattern

must

be replaced.

(2)

Mike

the

main bearings and connecting-rDd

bearings and also

the

crankshaft

journals

and crankpins

to

determine,

on

the

basis

of

ID readings and OD readings,

the

amount

of

oil clearance available in

each

fit. (A press

gauge can be used instead.)

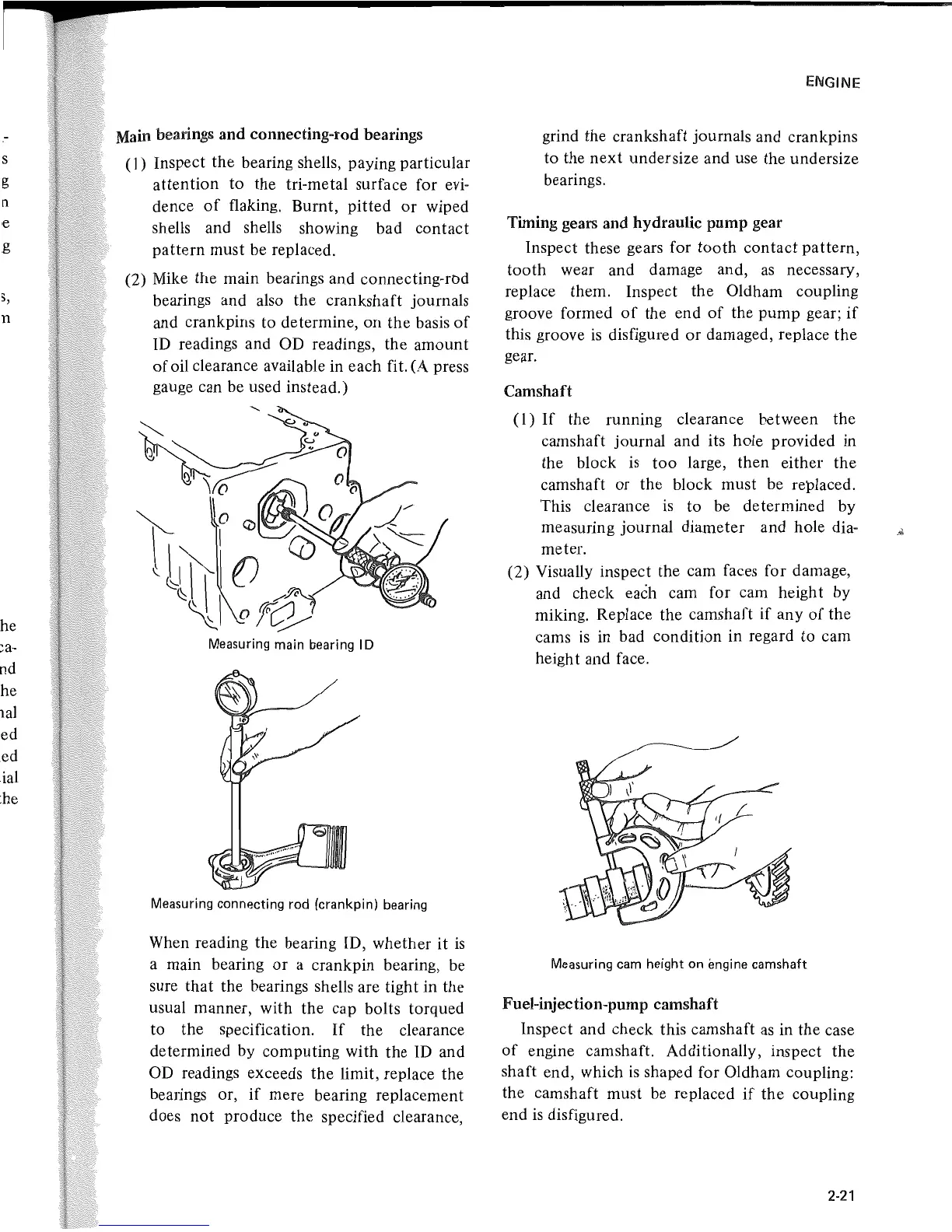

Measuring main bearing I D

Measuring connecting rod (crankpin) bearing

When reading

the

bearing ID,

whether

it

is

a main bearing

or

a crankpin bearing, be

sure

that

the

bearings shells are tight in the

usual manner,

with

the

cap bolts

torqued

to

the

specification.

If

the

clearance

determined

by

computing

with

the

ID and

OD readings exceeds

the

limit, replace the

bearings or,

if

mere

bearing replacement

does

not

produce

the

specified clearance,

ENGINE

grind

the

crankshaft journals and crankpins

to the

next

undersize and use

the

undersize

bearings.

Timing gears

and

hydraulic

pump

gear

Inspect these gears for

tooth

contact

pattern,

tooth

wear and damage and,

as

necessary,

replace them. Inspect

the

Oldham coupling

groove formed

of

the

end

of

the

pump

gear;

if

this groove is disfigured

or

damaged, replace

the

gear.

Camshaft

(1)

If

the

running clearance between

the

camshaft journal and its hole provided in

the

block is

too

large,

then

either

the

camshaft

or

the

block

must

be replaced.

This clearance is

to

be

determined

by

measuring

journal

diameter

and hole dia-

meter.

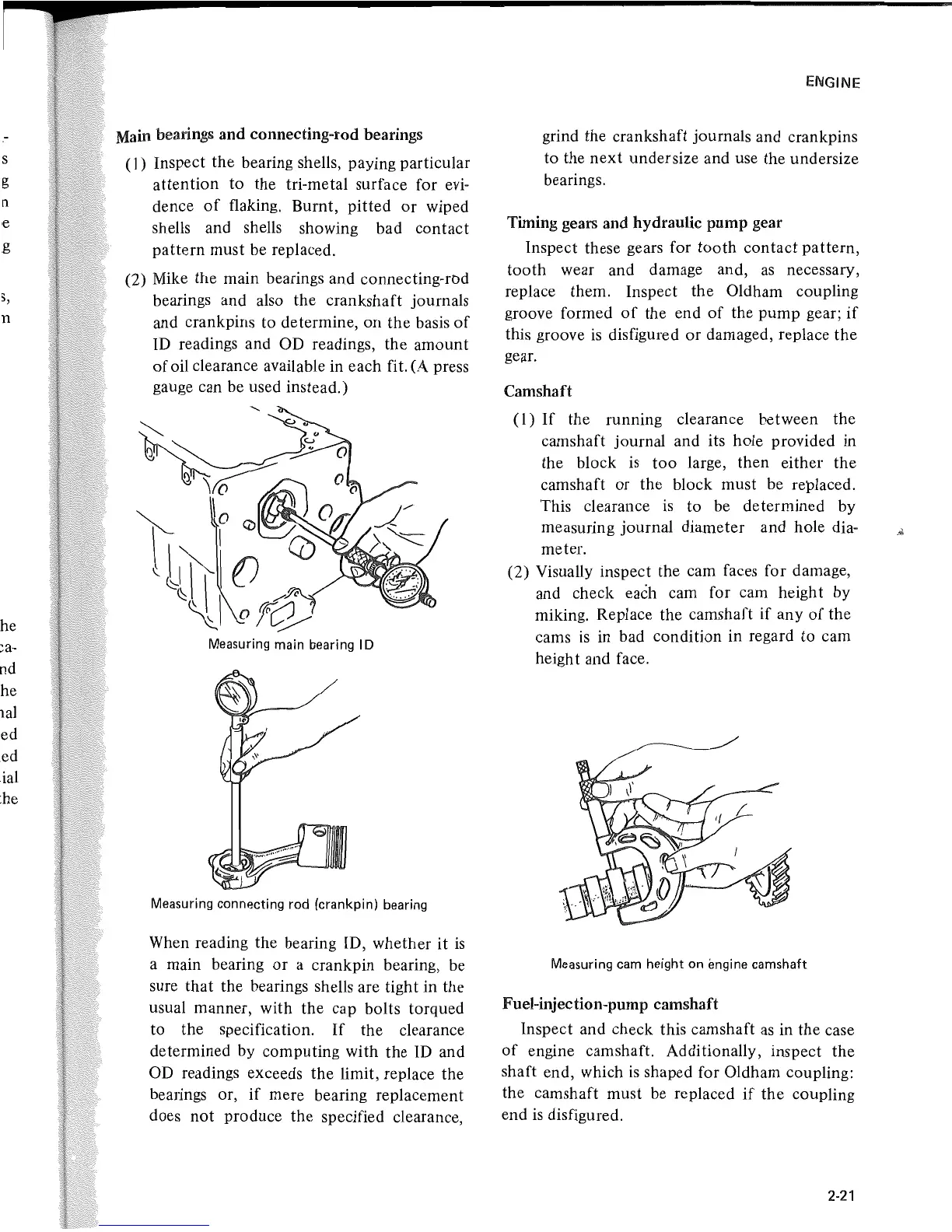

(2)

Visually inspect

the

cam faces for damage,

and check each cam for cam height by

miking. Replace the camshaft

if

any

of

the

cams

is

in bad

condition

in regard

to

cam

height and face.

Measuring cam height on engine camshaft

Fuel-injection-pump camshaft

Inspect and check this camshaft

as

in

the

case

of

engine camshaft. Additionally, inspect

the

shaft

end, which is shaped for Oldham coupling:

the

camshaft

must

be replaced

if

the

coupling

end is disfigured.

2-21

Loading...

Loading...