2200LZJE-HO-C6-N_2013.12.

Chapter 2 Configuration and Specifications of Compressor

Compound 2-stage Screw Compressor 2016**C 2.3 Compressor Specifications

2-3

2.3.2 Operation Limits

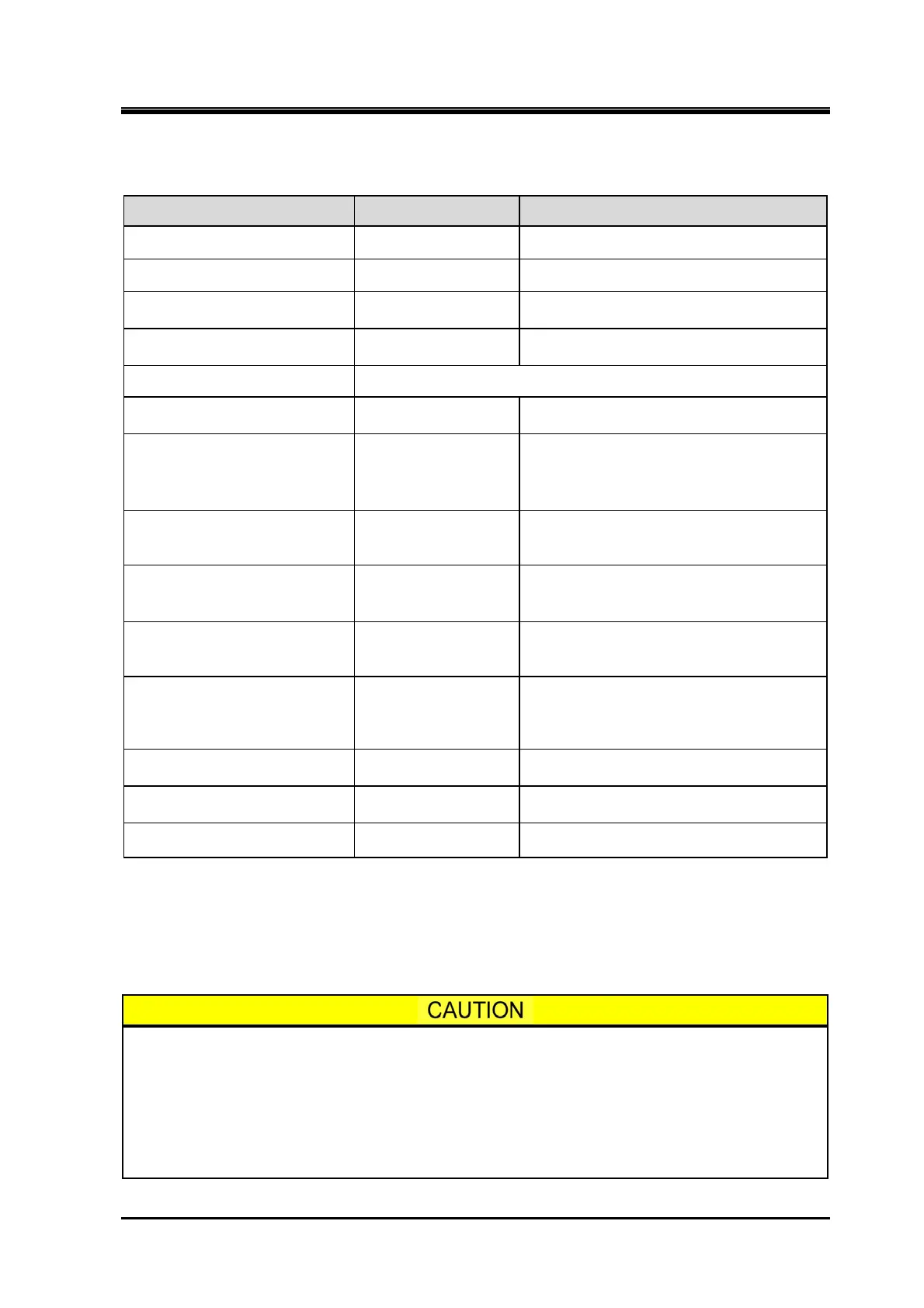

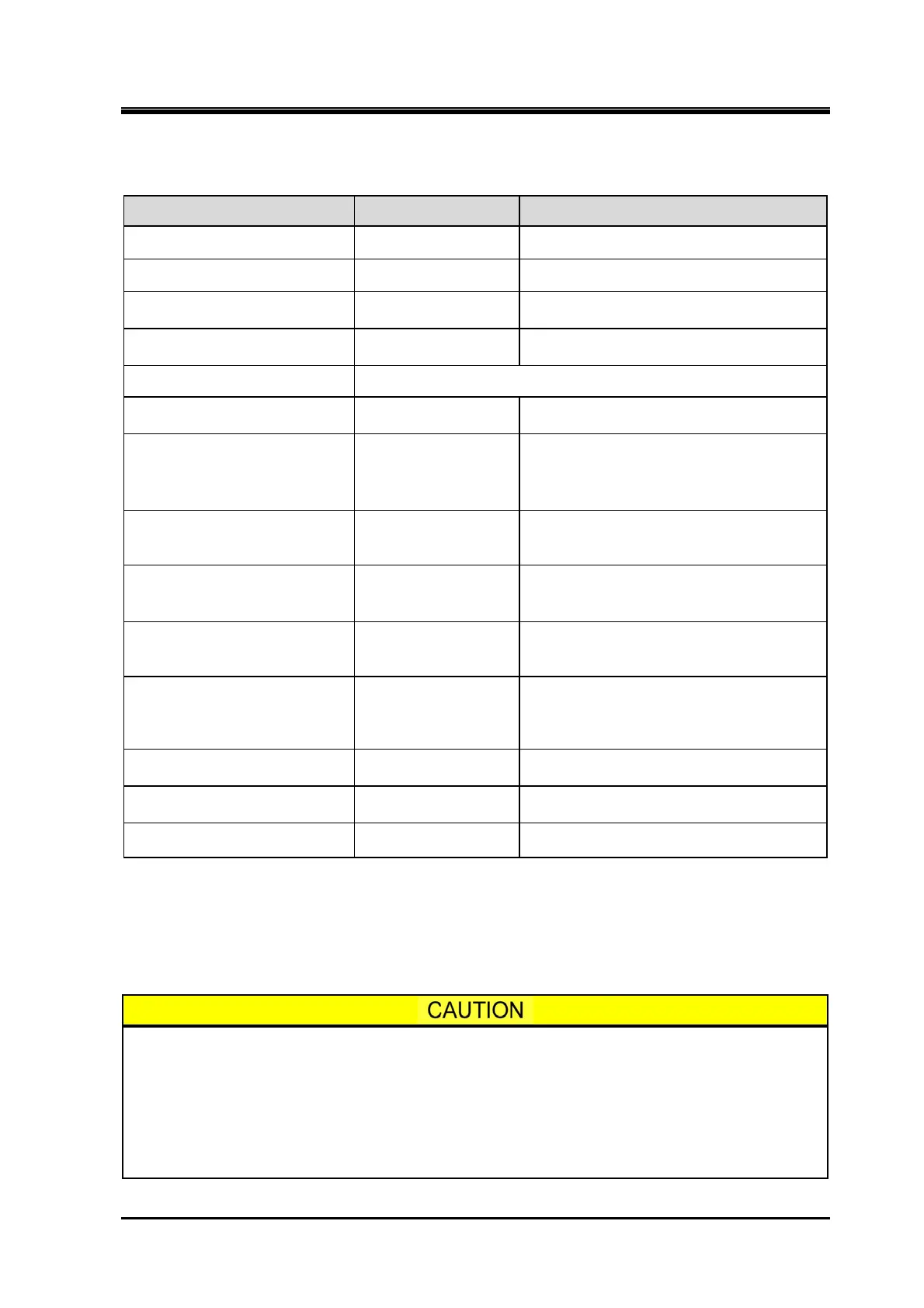

Table 2-2 Operation Limits of 2016**C

Items Operation Limits Remarks

Maximum discharge pressure 1.96 MPa *Note 1 Casing design pressure: 2.6 MPa

Minimum suction pressure -0.080 MPa Shaft seal, inherent properties

Maximum intermediate

pressure

0.588 MPa Bearing

Minimum intermediate pressure > Suction pressure

Recommended condition:

> Suction pressure + 0.1 MPa

Oil supply pressure Ps: Suction pressure, Pd: Discharge pressure

1) Journal lubrication

pressure

Pd + (0.049 to 0.39)

MPa

Balance piston lubrication

(Pressure lubrication)

2) Bearing and oil injection

minimum lubrication

pressure

Ps + 0.49 MPa

*Note 2

Check valve must be installed.

3) Balance piston minimum

lubrication pressure

Pd + 0.049 MPa

Suction temperature

max. 85°C

min. -60°C

Clearance allowed between rotor and

casing Casing design

Maximum discharge

temperature

Low-stage 90°C

High-stage 100°C

Clearance allowed between rotor and

casing

Maximum oil supply

temperature

60°C

Oil viscosity should be not less than

13mm

2

/s.

(Optimally, oil viscosity should be between

13 and 40 mm

2

/s.)

Minimum oil supply temperature 30°C

Oil viscosity should be not higher than

60mm

2

/s.

Maximum M rotor rotation

speed

4000 rpm Bearing, inherent properties, seal

Minimum M rotor rotation speed 1450 rpm Bearing

Note 1: Unless otherwise noted, the pressure unit MPa represents the gauge pressure in this manual.

Note 2: When it is required that pressure difference between Pd and Ps should be not greater than

0.49 MPa, oil pump needs to be installed.

If a combination of "NH

3

+ compatible oil (PN46)" is used for working fluid (refrigerant) and

lubricating oil, oil pump must be installed.

If operation at partial load, which is not greater than 30% of the indicated load, is

continued for a long time except when starting up the machine, abnormal noises

or vibration may be generated. So avoid such operation.

Repeated startup and stop in a short period is harmful not for the startup devices

and electric machinery but also for the compressor itself. For information on the

start/stop limitations, refer to each instruction manual. Wait at least 15 minutes

after stopping the compressor before restarting it.

Loading...

Loading...