2200LZJE-HO-C6-N_2013.12.

Chapter 3 Installation

Compound 2-stage Screw Compressor 2016**C 3.2 Installation Works

3-4

3.2.4 Preparation for Installation

Installation Space

Secure sufficient working space for easy operation, cleaning, maintenance, and inspection.

Illumination

Prepare illumination devices which allow easy operation, cleaning, maintenance, and inspection.

Ventilation

If natural ventilation is insufficient, install ventilation fans according to the relevant regulations.

Piping

Table 3-1 List of Connecting Pipes (Compressor)

Item Dimensions Remarks

Suction gas inlet JIS 20K 150A (6") See Figure 3-2.

Low-stage gas outlet JIS 20K 100A (4") See Figure 3-2.

High-stage gas inlet JIS 20K 100A (4") See Figure 3-2.

High-stage discharge gas outlet JIS 20K 80A (3") See Figure 3-2.

Lubrication oil supply port for low-stage

bearing (journal)

JIS 20K 25A (1")

Lubrication oil supply port for low-stage

capacity control (increased side)

Rc1/4

Lubrication oil supply port for low-stage

capacity control (decreased side)

Rc3/8

Oil supply port for oil injection

JIS 20K 15A (1/2")

Lubrication oil supply port for high-stage

bearing (journal)

JIS 20K 20A (3/4")

Lubrication oil supply port for high-stage

capacity control (increased side)

Rc3/8

Lubrication oil supply port for high-stage

capacity control (decreased side)

Rc1/4

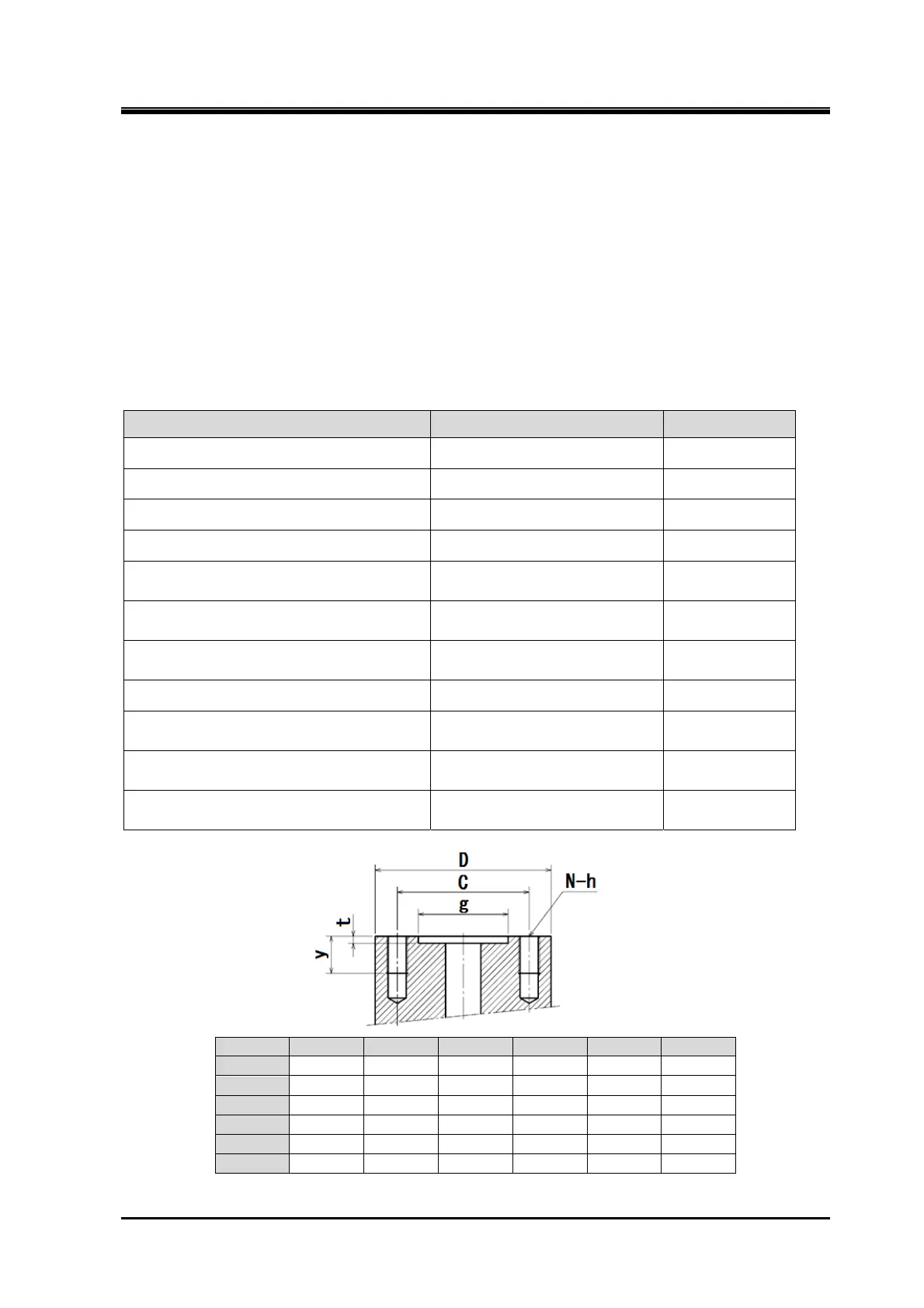

Figure 3-2 Dimensions of the Joint

D t g C N-h y

15A □ 74 5 43 70 4-M12 25

20A □ 84 5 51 75 4-M12 25

25A □100 5 61 90 4-M16 25

80A 200 5 121 160 8-M20 35

100A 225 5 146 185 8-M20 35

150A 305 5 216 260 12-M22 34

Loading...

Loading...