2200LZJE-HO-C6-N_2013.12.

Chapter 5 Maintenance

Compound 2-stage Screw Compressor 2016**C 5.7 Reassembly

5-48

5.7.7 Thrust Bearings (High/Low-stage)

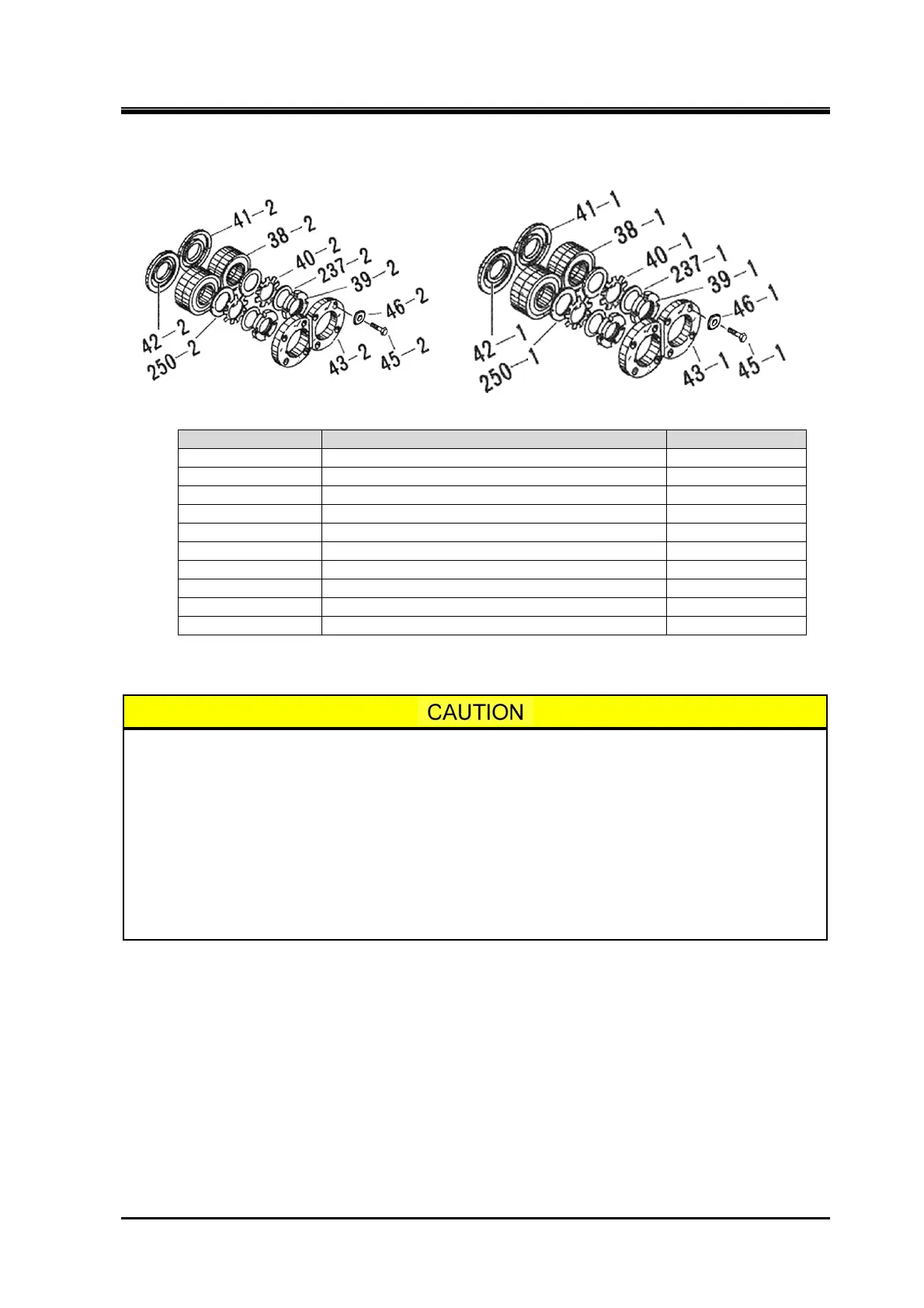

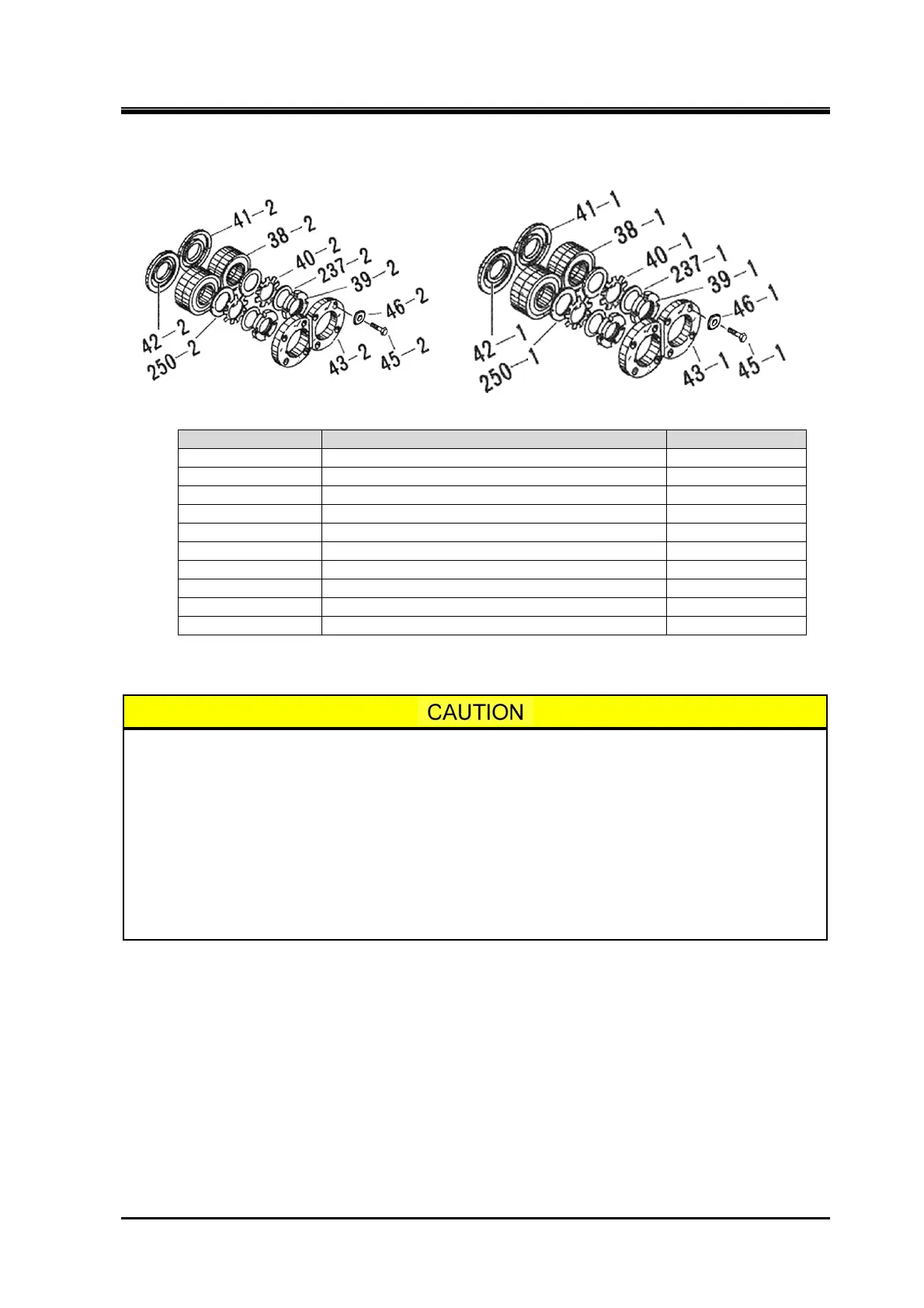

【High-stage】 【Low-stage】

No. Part name Qty.

42-1, 42-2 Thrust bearing alignment spacer (1), (2) Two for each

41-1, 41-2 Thrust bearing outer race spacer (1), (2) Two for each

38-1, 38-2 Thrust bearing (1), (2) Two sets for each

250-1, 250-2 Thrust washer (1), (2) Two for each

40-1, 40-2 Lock washer (1), (2) Two for each

237-1, 237-2 Torsional slip washer (1), (2) Two for each

39-1, 39-2 Lock nut (1), (2) Two for each

43-1, 43-2 Thrust bearing gland (1), (2) Two for each

46-1, 46-2 Conical spring washer (1), (2) Eight for each

45-1, 45-2 Hexagon head bolt (1), (2) Eight for each

Figure 5-9 Development View of the Thrust Bearing Part

When assembling the disassembled thrust bearing without replacing any parts,

check the M and F stamp marks on the thrust bearing outer race spacer and

thrust bearing alignment spacer, and reassemble them in the same way as before

disassembly. This is essential to control the end clearance of the rotor discharge

side.

Even when assembling the same bearing, dimensions may become incorrect if

flakes of paint or dirt are caught between spacers and alignment spacers.

Regarding the direction of thrust bearing assembly, there may or may not be a

V-shaped mark for assembly on the outer periphery of the bearing. Follow the

instructions below for each case of assembling.

a) The procedure for assembling this portion is described in Figure 5-9. The important points are

explained below.

If there is a V-shaped mark for assembly on the outer side of the thrust bearing, assemble with the

pointed end of the mark on the inner side of the machine, as there is a slight directional difference

that affects end clearance adjustment.

If there is no V-shaped mark, assembly direction does not affect end clearance adjustment.

However, to clarify the difference between the inner side and outer side of the machine, assemble

the thrust bearing with the bearing number stamped on the outer side. Then, put down a V-shaped

mark on the side which is to be attached to the inner side of the machine, by using blue whetstone.

Loading...

Loading...