Supply Tank Lower Than Engine: With this installation,

the day tank is installed near the generator set and

within the engine fuel pump lift capability, but below the

fuel injection system. Install an auxiliary fuel pump as

close as possible to the supply tank to pump fuel from

the supply tank to the day tank. A float switch in the day

tank controls operation of the auxiliary fuel pump.

The supply tank top must be below the day tank top to prevent

siphoning from the fuel supply tank to the day tank.

Provide a return line from the engine injection system

return connection to the day tank (near the

top).

Provide

a day tank overflow line to the supply tank in case the

float switch fails to shut off the fuel transfer pump.

AWARNING

Spilled fuel presents the hazard of

fire or explosion which can result in

severe personal injury or death. Provide an overflow

line to the

supply

tank from the day tank.

Supply Tank Higher Than Engine: Install the day tank

near the generator set and within the engine fuel pump

lift capability, but below the fuel injection system. Use

fuel line at least as large as the fuel pump inlet. The

engine fuel return line must-enter the day tank.

Include a shutoff solenoid in the fuel line between the

fuel supply tank and the day tank. It stops fuel flow when

the generator set is off.

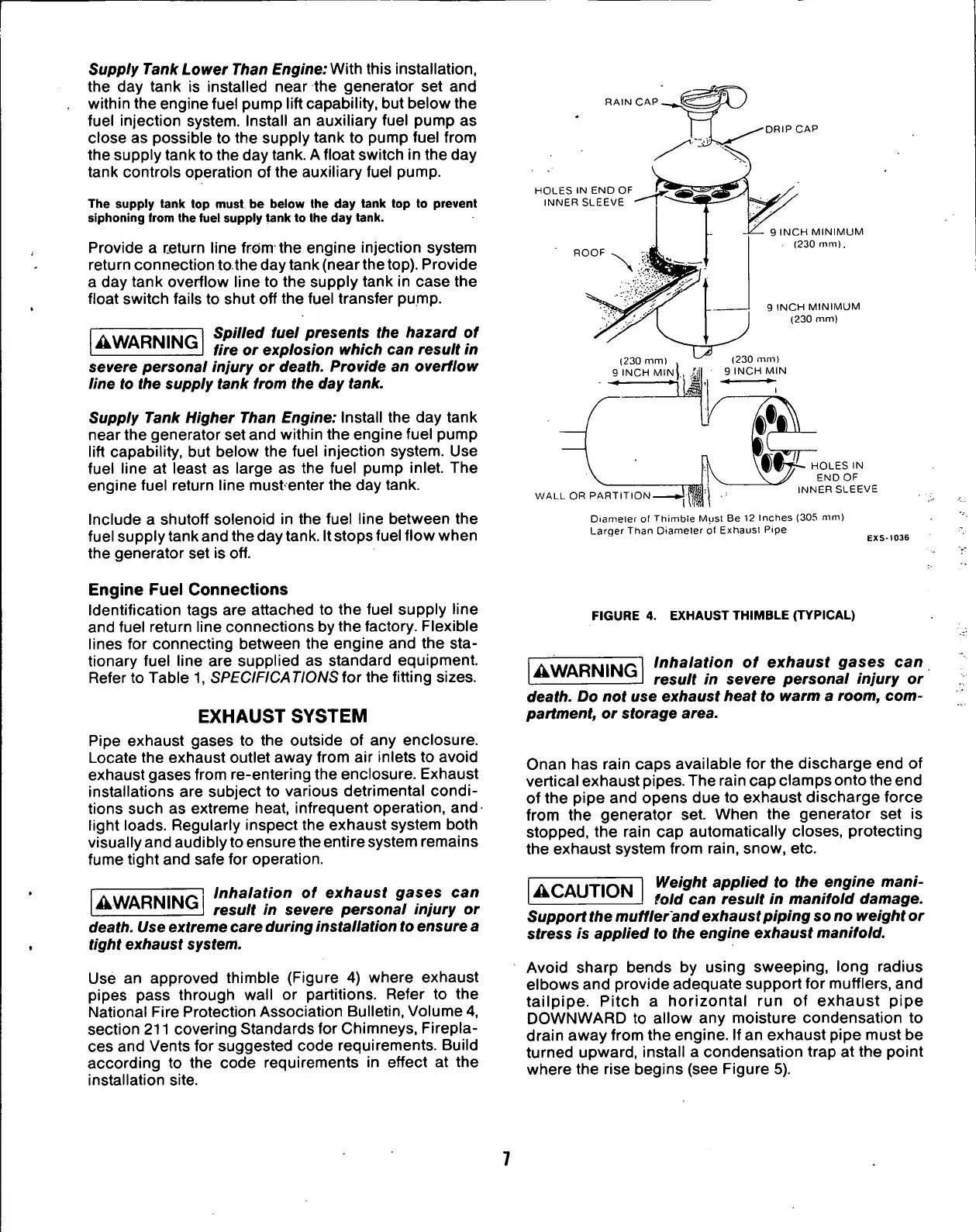

RAIN CAP

DRIP CAP

HOLES IN END OF

INNER SLEEVE

ROOF

9 INCH MINIMUM

(230 mm).

9 INCH MINIMUM

(230 mm)

(230 mm) (230 mm)

9 INCH MIN , tt 9 INCH MIN

WALL OR PARTITION

,1)1^/-

HOLES IN

V

END

OF

INNER SLEEVE

Diameter ol Thimble Must Be 12 Inches (305 mm)

Larger Than Diameter of Exhaust Pipe

EXS-1036

Engine

Fuel

Connections

Identification tags are attached to the fuel supply line

and fuel return line connections by the factory. Flexible

lines for connecting between the engine and the sta-

tionary fuel line are supplied as standard equipment.

Refer to Table 1, SPECIFICATIONS tor the fitting sizes.

EXHAUST

SYSTEM

Pipe exhaust gases to the outside of any enclosure.

Locate the exhaust outlet away from air inlets to avoid

exhaust gases from re-entering the enclosure. Exhaust

installations are subject to various detrimental condi-

tions such as extreme heat, infrequent operation, and

light loads. Regularly inspect the exhaust system both

visually and audibly to ensure the entire system remains

fume tight and safe for operation.

AWARNING

Inhalation of exhaust gases can

result in severe personal injury or

death. Use extreme care during installation

to

ensure a

tight exhaust

system.

Use an approved thimble (Figure 4) where exhaust

pipes pass through wall or partitions. Refer to the

National Fire Protection Association Bulletin, Volume 4,

section 211 covering Standards for Chimneys, Firepla-

ces and Vents for suggested code requirements. Build

according to the code requirements in effect at the

installation site.

FIGURE 4. EXHAUST THIMBLE (TYPICAL)

AWARNING

Inhalation of exhaust gases can

result in severe personal injury or

death. Do not use exhaust heat to warm a room, com-

partment, or storage area.

Onan has rain caps available for the discharge end of

vertical exhaust pipes. The rain cap clamps onto the end

of the pipe and opens due to exhaust discharge force

from the generator set. When the generator set is

stopped,

the rain cap automatically closes, protecting

the exhaust system from

rain,

snow, etc.

ACAUTION

Weight applied to the engine mani-

fold can result in manifold damage.

Support

the

mufflerand exhaust piping

so

no weight

or

stress is applied to the engine exhaust manifold.

Avoid sharp bends by using sweeping, long radius

elbows and provide adequate support for mufflers, and

tailpipe. Pitch a horizontal run of exhaust pipe

DOWNWARD to allow any moisture condensation to

drain away from the engine. If an exhaust pipe must be

turned upward, install a condensation trap at the point

where the rise begins (see Figure 5).

Loading...

Loading...