GENERAL

MAINTENANCE

GENERAL

Establish and adhere to a definite schedule of

maintenance inspection and servicing, application

and environment being the governing factors in

determining such a schedule. If your set is a prime

power application, base your schedule on operating

hours.

Use the running time meter to log hours run;

maintain an accurate record of hours and service for

vyarranty support

A set on stand-by duty will need servicing at times

other than those recommended by Onan and the

engine manufacturer. Referto Allis-Chalmers manual

for engine services and maintenance procedures.

Adjust your schedule to satisfy the following

conditions—

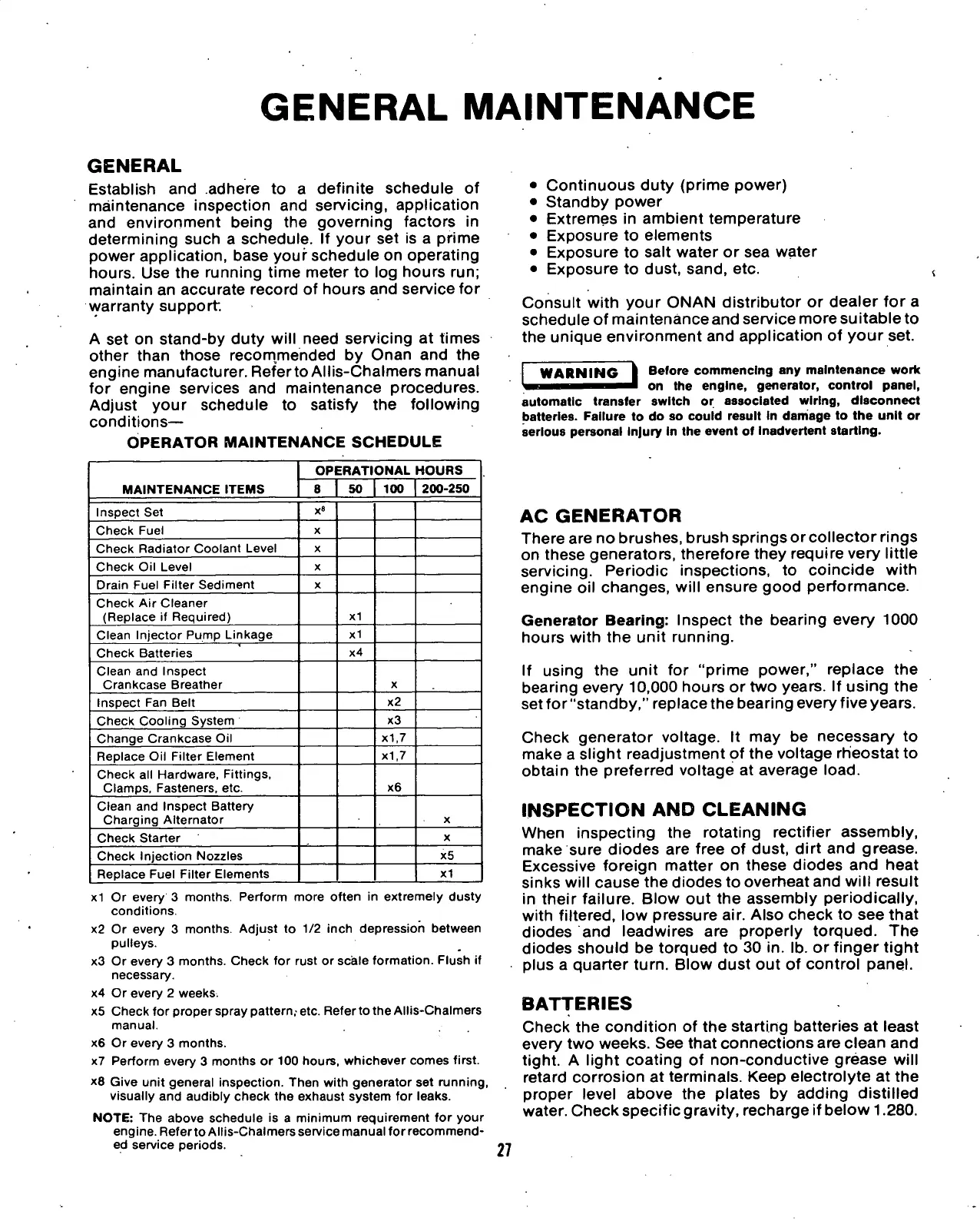

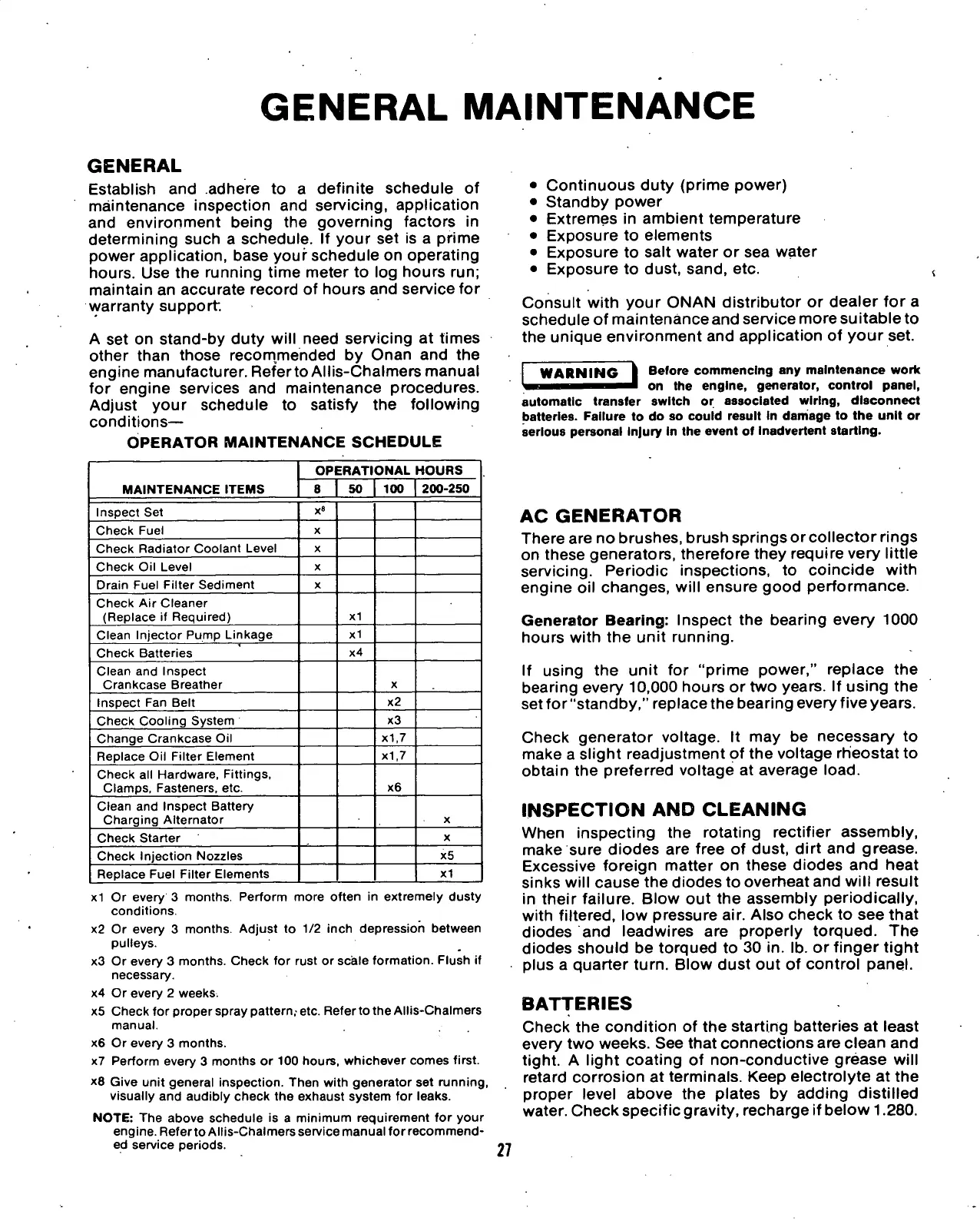

OPERATOR

MAINTENANCE

SCHEDULE

MAINTENANCE ITEMS

OPERATIONAL HOURS

MAINTENANCE ITEMS

8

50 100 200-250

Inspect Set

x«

Check Fuel

X

Check Radiator Coolant Level

X

Check Oil Level

X

Drain Fuel Filter Sediment

X

Check Air Cleaner

(Replace if Required)

xl

Clean Injector Pump Linkage

xl

Check Batteries

x4

Clean and Inspect

Crankcase Breather

X

Inspect Fan Belt

x2

Check Cooling System

x3

Change Crankcase Oil

x1,7

Replace Oil Filter Element

x1,7

Check all Hardware, Fittings,

Clamps, Fasteners, etc.

x6

Clean and Inspect Battery

Charging Alternator

X

Check Starter

X

Check Injection Nozzles

x5

Replace Fuel Filter Elements

x1

xl Or every 3 months. Perform more often in extremely dusty

conditions.

x2 Or every 3 months. Adjust to 1/2 inch depression between

pulleys.

x3 Or every 3 months. Check for rust or scale formation. Flush if

necessary.

x4 Or every 2 weeks.

x5 Check for proper spray pattern,-etc. Refer to the Allis-Chalmers

manual.

x6 Or every 3 months.

x7 Perform every 3 months or 100 hours, whichever comes first.

x8 Give unit general inspection. Then with generator set running,

visually and audibly check the exhaust system for leaks.

NOTE:

The above schedule is a minimum requirement for your

engine. Refer to Allis-Chalmers service manual for recommend-

ed service periods.

• Continuous duty (prime power)

• Standby power

• Extremes in ambient temperature

• Exposure to elements

• Exposure to salt water or sea water

• Exposure to dust, sand, etc.

Consult with your ONAN distributor or dealer for a

schedule of maintenance and service more suitable to

the unique environment and application of your set.

WARNING

Before commencing any maintenance work

on the engine, generator, control panel,

automatic transfer switch or associated wiring, disconnect

batteries. Failure to do so could result in damage to the unit or

serious personal Injury In the event of Inadvertent starting.

AC

GENERATOR

There are no brushes, brush springs orcollector rings

on these generators, therefore they require very little

servicing.

Periodic inspections, to coincide with

engine oil changes, will ensure good performance.

Generator Bearing: Inspect the bearing every 1000

hours with the unit running.

If using the unit for "prime power," replace the

bearing every 10,000 hours or two years. If using the

set for "standby," replace the bearing every five years.

Check generator voltage. It may be necessary to

make a slight readjustment of the voltage rheostat to

obtain the preferred voltage at average

load.

INSPECTION

AND

CLEANING

When inspecting the rotating rectifier assembly,

make sure diodes are free of dust, dirt and grease.

Excessive foreign matter on these diodes and heat

sinks will cause the diodes to overheat and will result

in their failure. Blow out the assembly periodically,

with filtered, low pressure air. Also check to see that

diodes and leadwires are properly torqued. The

diodes should be torqued to 30 in. Ib. or finger tight

plus a quarter

turn.

Blow dust out of control panel.

BATTERIES

Check the condition of the starting batteries at least

every two weeks. See that connections are clean and

tight. A light coating of non-conductive grease will

retard corrosion at terminals. Keep electrolyte at the

proper level above the plates by adding distilled

water. Check specific gravity, recharge if below

1.280.

27

Loading...

Loading...