4-1

4. Periodic Maintenance

Periodic maintenance is essential for top perfor-

mance and long genset life. Use Table 4-1 as a

guide for normal periodic maintenance.

Maintenance, replacement or repair of emission

control devices and systems may be performed by

any engine repair establishment or individual. How-

ever, warranty work must be completed by an au-

thorized Onan service representative.

WARNING

Accidental or remote starting can

cause severe personal injury or death. Discon-

nect the negative (−) cable at the battery to pre-

vent starting while working on the genset.

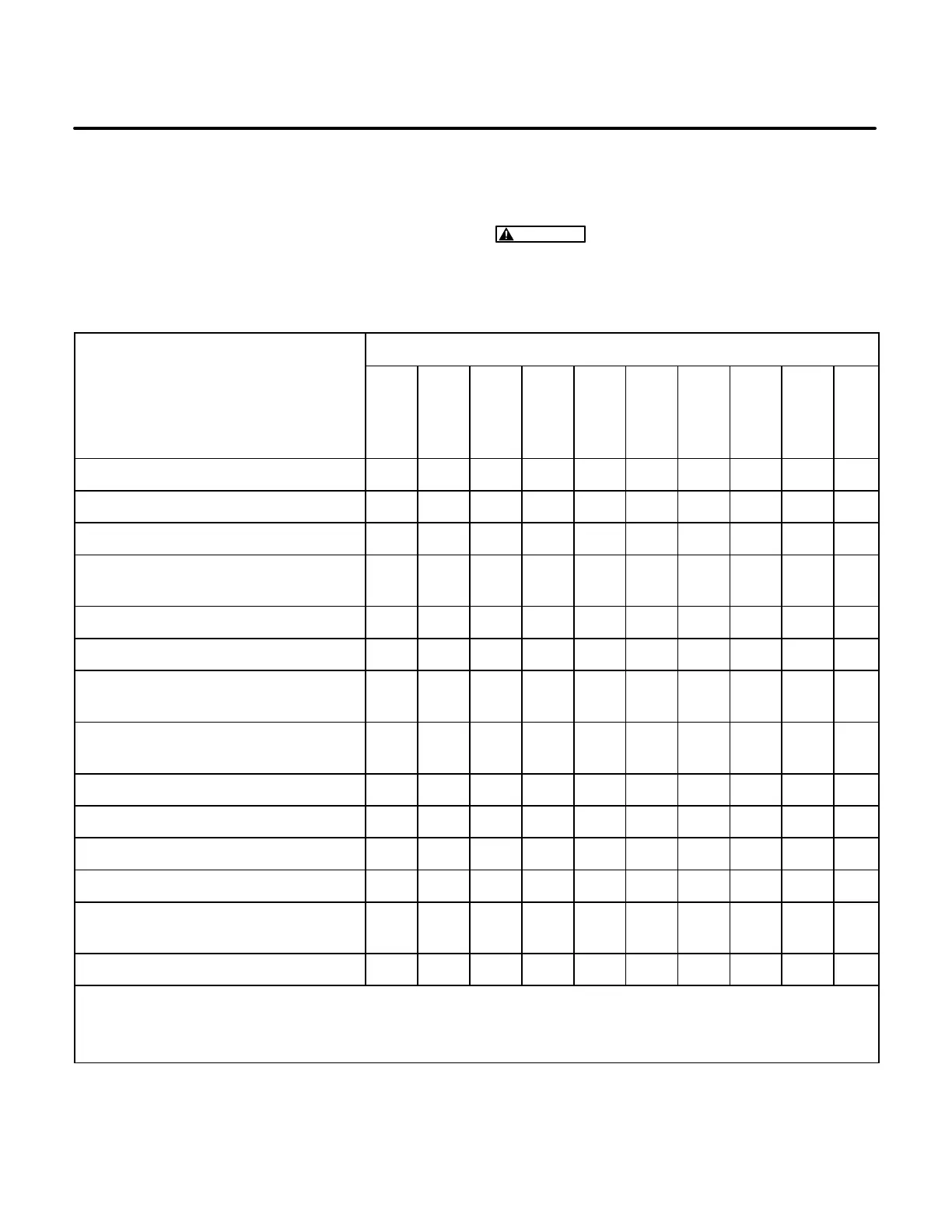

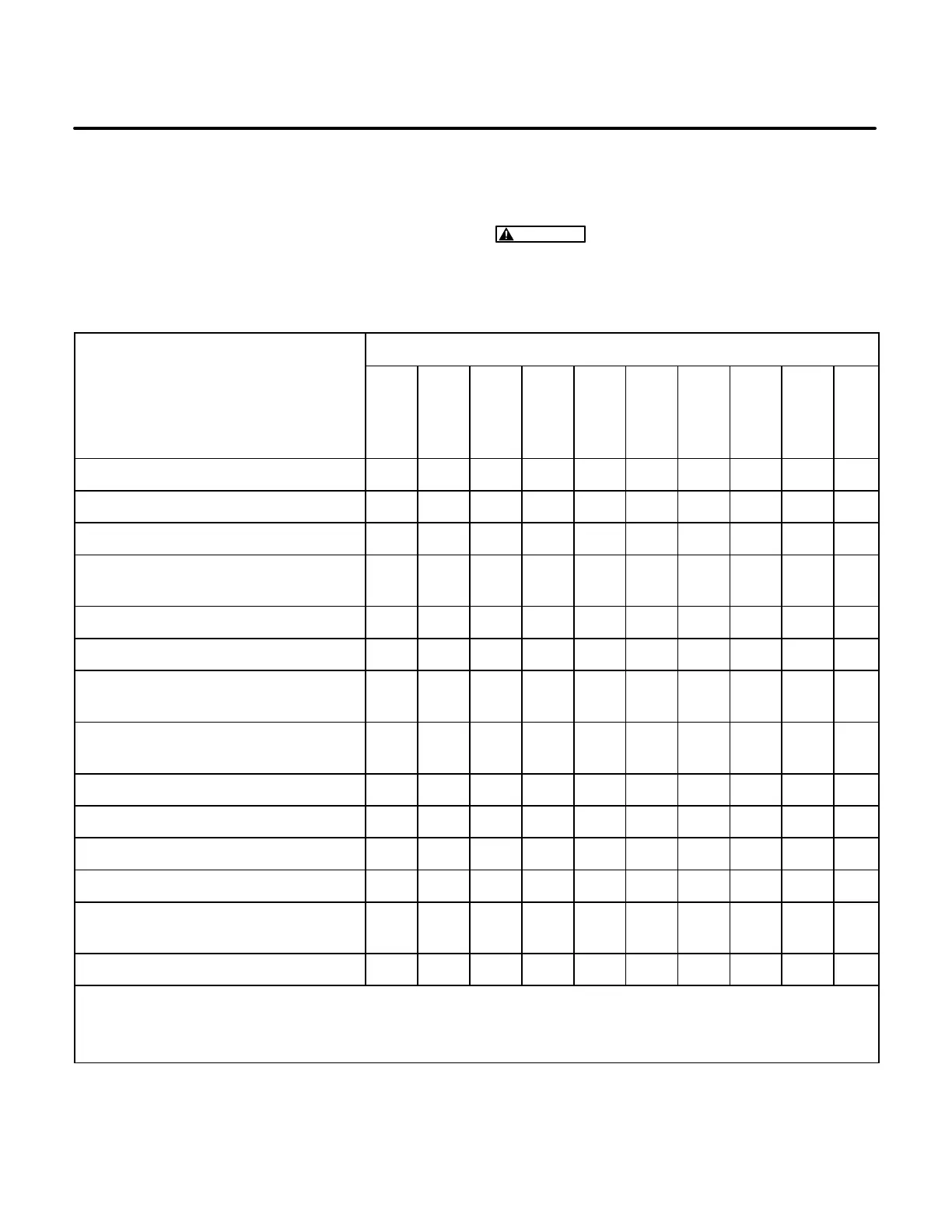

TABLE 4-1. PERIODIC MAINTENANCE SCHEDULE

MAINTENANCE FREQUENCY

MAINTENANCE OPERATION

After

First

50 Hrs

Every

Day /

8 Hrs

Every

Month/

100

Hrs

Every

Year/

200

Hrs

Every

Year/

350

Hrs

Every

Year/

500

Hrs

Every

800

Hrs

Every

2

Years

Every

5

Years/

2000

Hrs

Page

General Inspection

1

•

4-2

Check Engine Oil Level •

4-3

Drain Water from Fuel Filter •

4-6

Inspect Battery and Battery Connec-

tions

2

•

4-2

Check V-Belt Tension

3

•

4-13

Inspect Siphon Break •

4-8

Change Engine Oil and Oil Filter—

All except MDKBT &MDKBU

• •

4-3

Change Engine Oil and Oil Filter—

Only MDKBT &MDKBU

• •

4-3

Replace Fuel Filters •

4-6

Inspect Zinc Anode •

4-8

Replace Raw Water Impeller •

4-12

Adjust Engine Valve Lash

4

•

−

Replace Coolant, Pressure Cap &

Thermostat

•

4-7

Inspect Generator Bearing

4

•

−

1 − Includes inspection of Oil Level, Coolant Level, Fuel System, Exhaust System, Batteries and Battery Connections.

2 − See battery manufacturer’s recommendations.

3 − Check for slippage, cracking and wear.

4 − Must be performed by a qualified mechanic (authorized Onan dealer).

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...