7-1

7. Generator

OVERVIEW

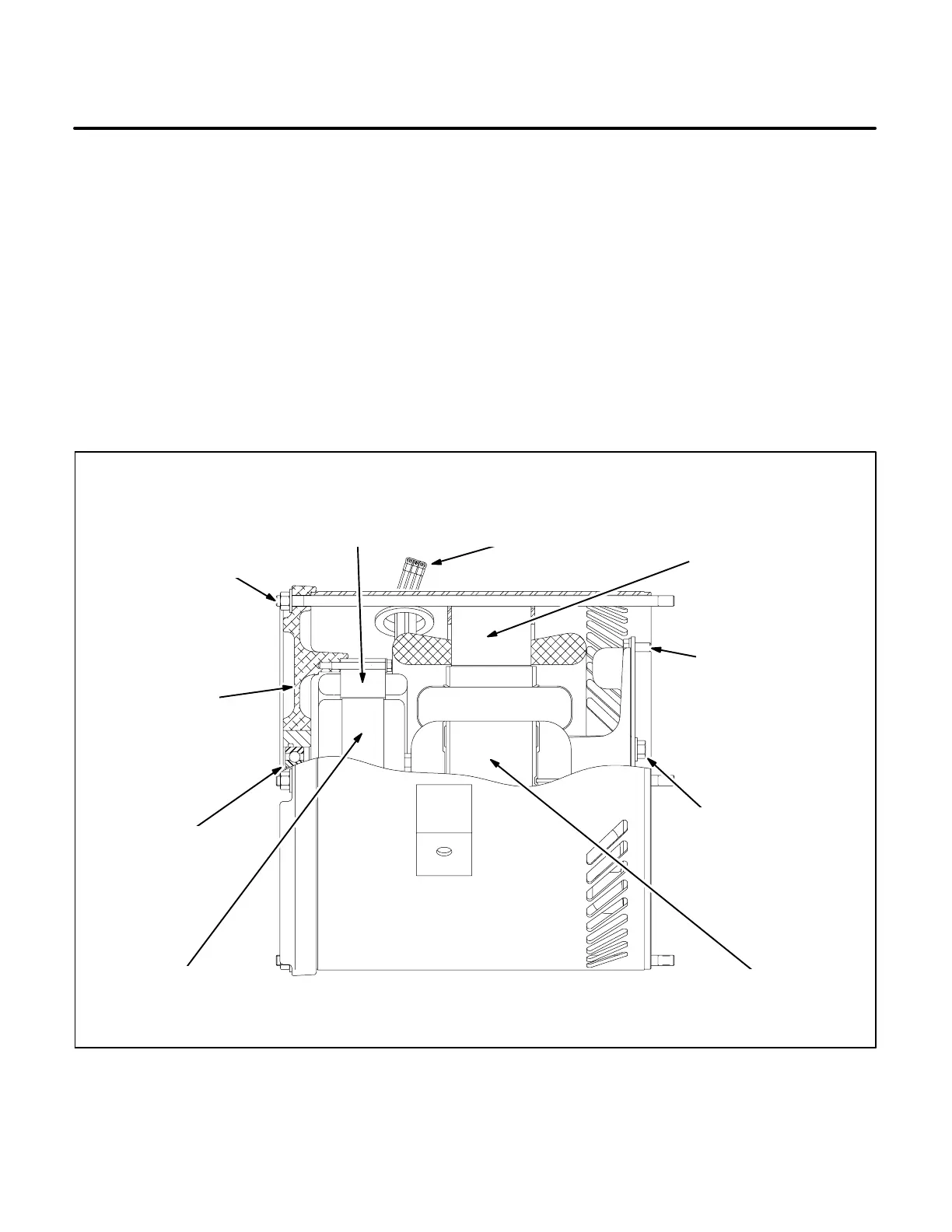

These are 4-pole, rotating-field, brushless, single-

bearing generators (Figure 7-1). Operation is as fol-

lows:

1. The engine rotates the generator field (main ro-

tor) to induce output current (AC) in the main

stator windings.

2. Generator output is proportional to the main ro-

tor (field) current supplied by the exciter rotor

through its full-wave rectifier bridge (rotating

rectifiers).

3. The genset controller (p. 5-1) rectifies and

modulates quadrature winding output (Q1, Q2)

to supply the exciter stator (F1, F2). By compar-

ing generator output voltage with a reference

value the genset control regulates field current

to maintain nominal output voltage as load var-

ies. Also, in response to transient loads, it low-

ers the voltage setpoint to allow for engine re-

covery.

4. Residual field magnetism and a permanent

magnet in one of the exciter stator poles initi-

ates “self-excitation” during startups.

GENERATOR STATOR

(MAIN & QUADRATURE

WINDINGS)

END BELL

ASSEMBLY

ROTOR

BEARING

MAIN ROTOR

(FIELD)

DRIVE DISC BOLT (6)

TORQUE DRY TO

27−31 N-M (20−23 FT-

LB)

SMOOTH, ROUNDED

SIDES OF WASHERS

TOWARD DISC

THROUGH BOLT (4)

TORQUE DRY TO

38−43 N-M

(28−32 FT-LB)

EXCITER

ROTOR

EXCITER

STATOR

STATOR, QUADRATURE, FIELD,

& VOLTAGE SENSING LEADS

DISC HUB BOLT(6)

TORQUE DRY TO

50−57 N-M (37−42 FT-

LB) SMOOTH,

ROUNDED SIDES OF

WASHERS TOWARD

DISC

FIGURE 7-1. TYPICAL GENERATOR

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...