27

Refuelling technique is important for good performance. The best efficiency and performance

from your insert can be achieved by adding partial loads of fuel and allowing them to get up to

operating temperature before adding additional fuel. Adding a large amount of fuel at one time

will increase the time required to get the fuel up to its ignition temperature, and an extended time

to reach optimal performance. When refuelling, open the air control or hold the door partially

open 1” (25 mm) or less, long enough (less than 5 minutes) so that the fire has well-established

flames. When refuelling, care is required to ensure that fuel or embers do not fall out of the door

opening.

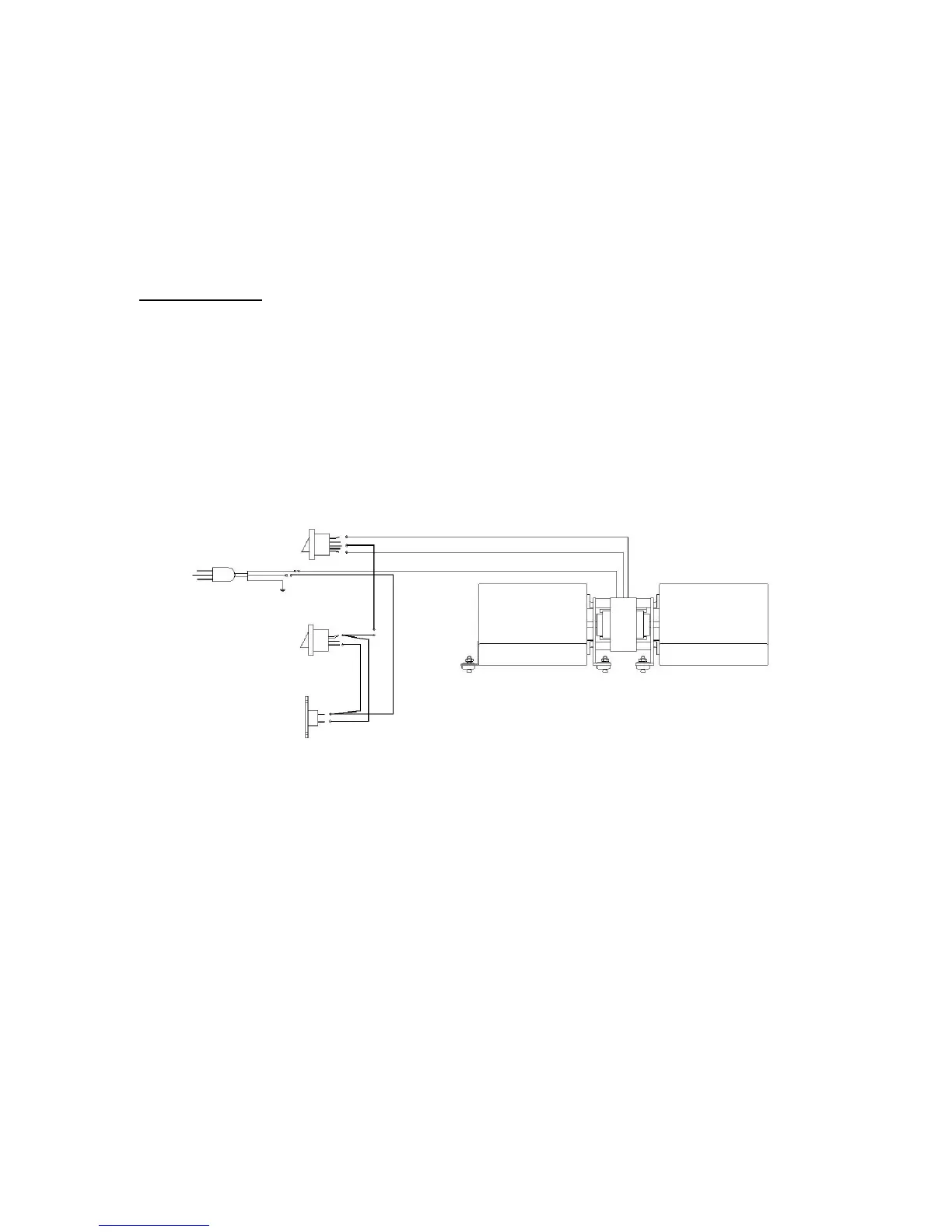

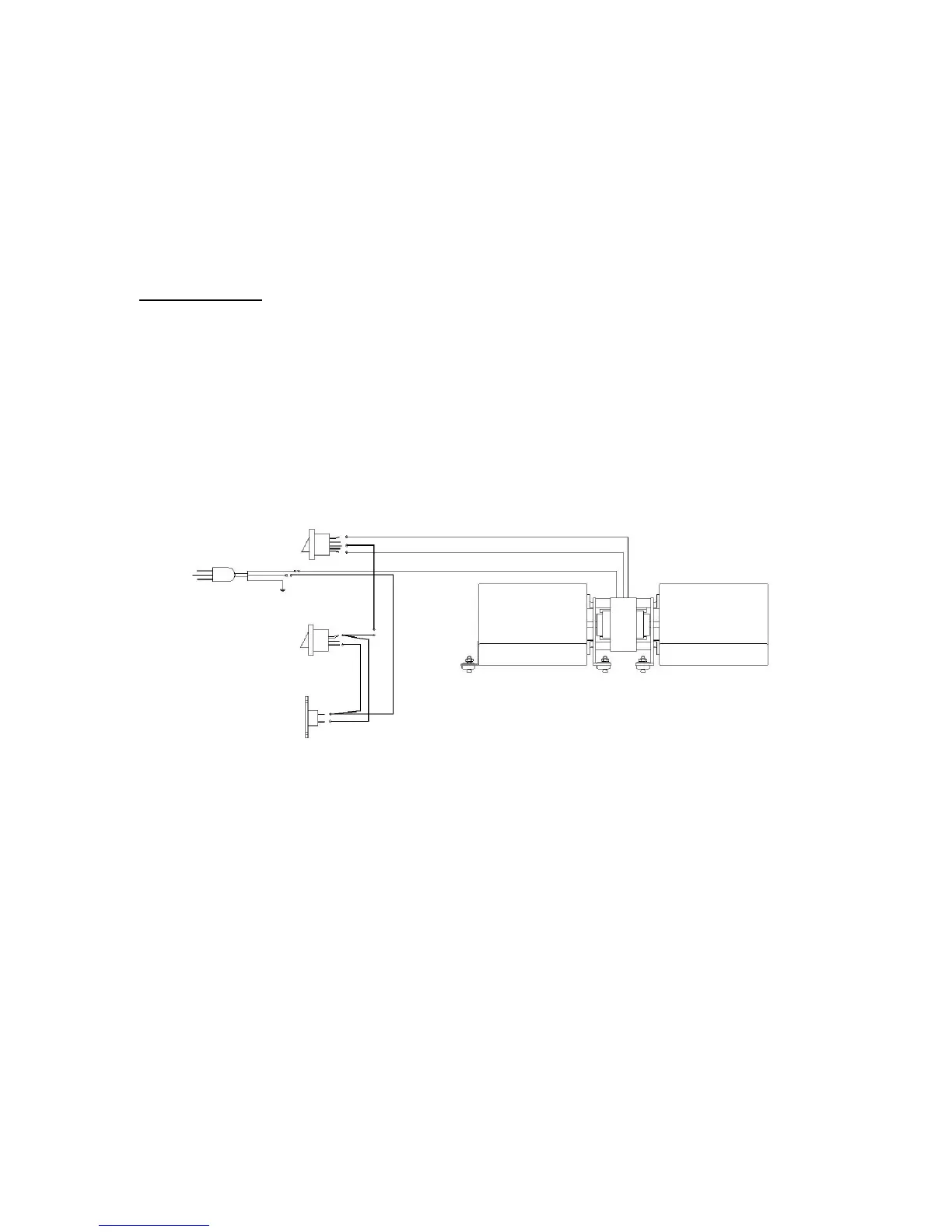

3.6 Fan operation

Allow the insert to heat up to operating temperature before turning on the fan. Increased airflow

from the fan will remove heat and affect the combustion efficiency during start-up. For this

reason we equipped the fan assembly with a heat sensor which will activate the blower at the

selected speed. The 3 position rocker switch is to control the blower speed « Low towards the

bottom – Off in the middle – Hi towards the top », « Low » being the minimum air flow, « Off » to

stop air circulation and « Hi » being the maximum air flow. If you prefer to control the blower

manually and at any time you will need to bypass the heat sensor. The heat sensor is bypassed

when the 2 position rocker switch is set to OFF.

The fan should be kept clean and dust free. Life of the fan will be shortened if operated in a dust

filled environment, or if the fan is overheated by restricting air supply. Stalling the motor, or over

firing the insert with the fan turned off will also damage the fan. The fan must not be over

heated.

Loading...

Loading...