9.8.8. Four-way Valve Error Detection Control

• The four-way valve error detection control starts when:

− During cooling operation, when indoor heat exchanger temperature exceeds 45°C in 5 minutes after compressor starts.

− During heating operation, when indoor heat exchanger temperature is below 5°C in 5 minutes after compressor starts.

• During four-way valve error, compressor is shut down and indoor unit is set to thermo-off status.

• After 3 occasions, four-way valve error is displayed; all operations stopped except outdoor fan remaining heat removal control.

9.8.9. Valve Error Detection Control

• This control is to protect the compressor.

• Valve error is detected if comply with condition below:

− Power is on for the first time and within 5 minutes from compressor starts (However, the unit is considered power on for first

time when compressor starts operating continuously for 7 minutes).

− Indoor heat exchanger temperature at compressor start -3°C < current heat exchanger temperature for 1 minute.

• During this error, four-way valve error is displayed; compressor is shutdown.

9.8.10. High-pressure Switch Disconnection Error Detection Control

• High-pressure switch disconnection is detected when high-pressure switch input continuously open for 1 minute while the

compressor shutdown.

• During this error, high-pressure switch error is displayed.

9.8.11. Low-pressure Switch Disconnection Error Detection Control

• Low-pressure switch disconnection is detected when low-pressure switch input continuously open for 1 minute while

compressor shutdown.

• During this error, low-pressure switch error is displayed.

9.9. Test run

• Test run is necessary after installation is completed.

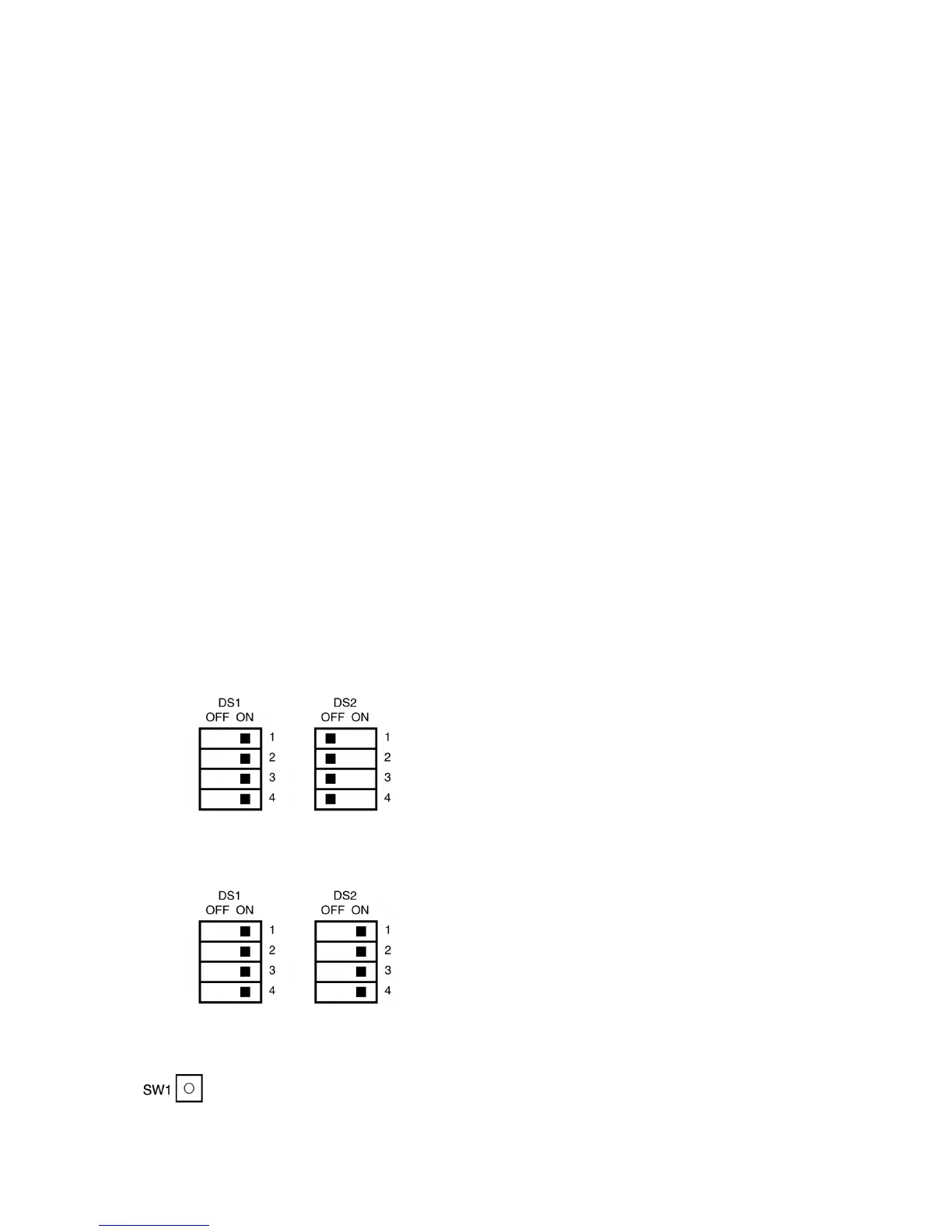

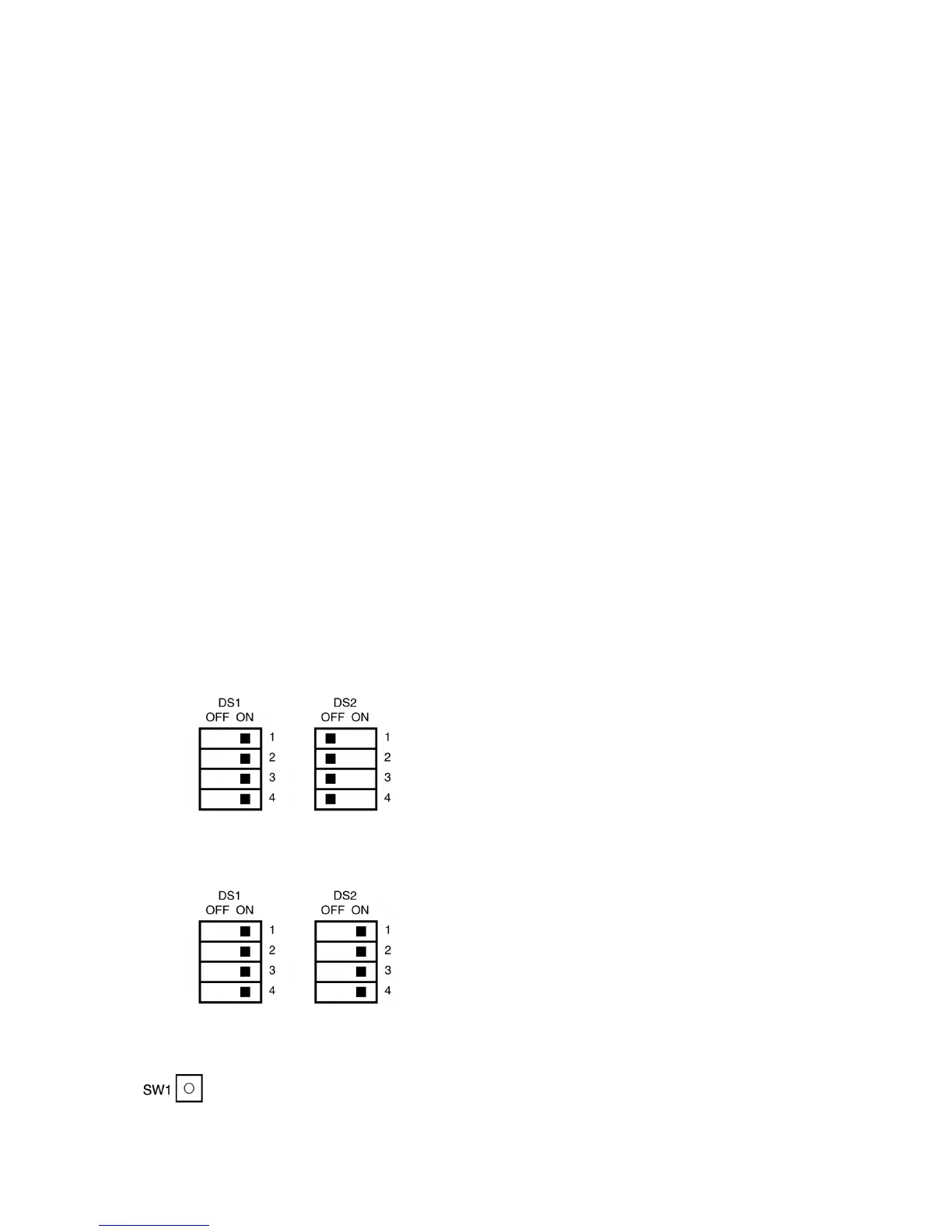

• To enable forced cooling test run, at outdoor PCB, set the DS1 to ON position and DS2 to OFF position.

• To enable forced heating test run, at outdoor PCB, set the DS1 to ON position and DS2 to ON position.

• Press Test Run button for 1 second. SW1 located at outdoor printed circuit board.

41

Loading...

Loading...