13

INTELLIFLO3™ VSF / INTELLIPRO3™ VSF Variable Speed and Flow Pump Installation and Maintenance Guide

MAINTENANCE

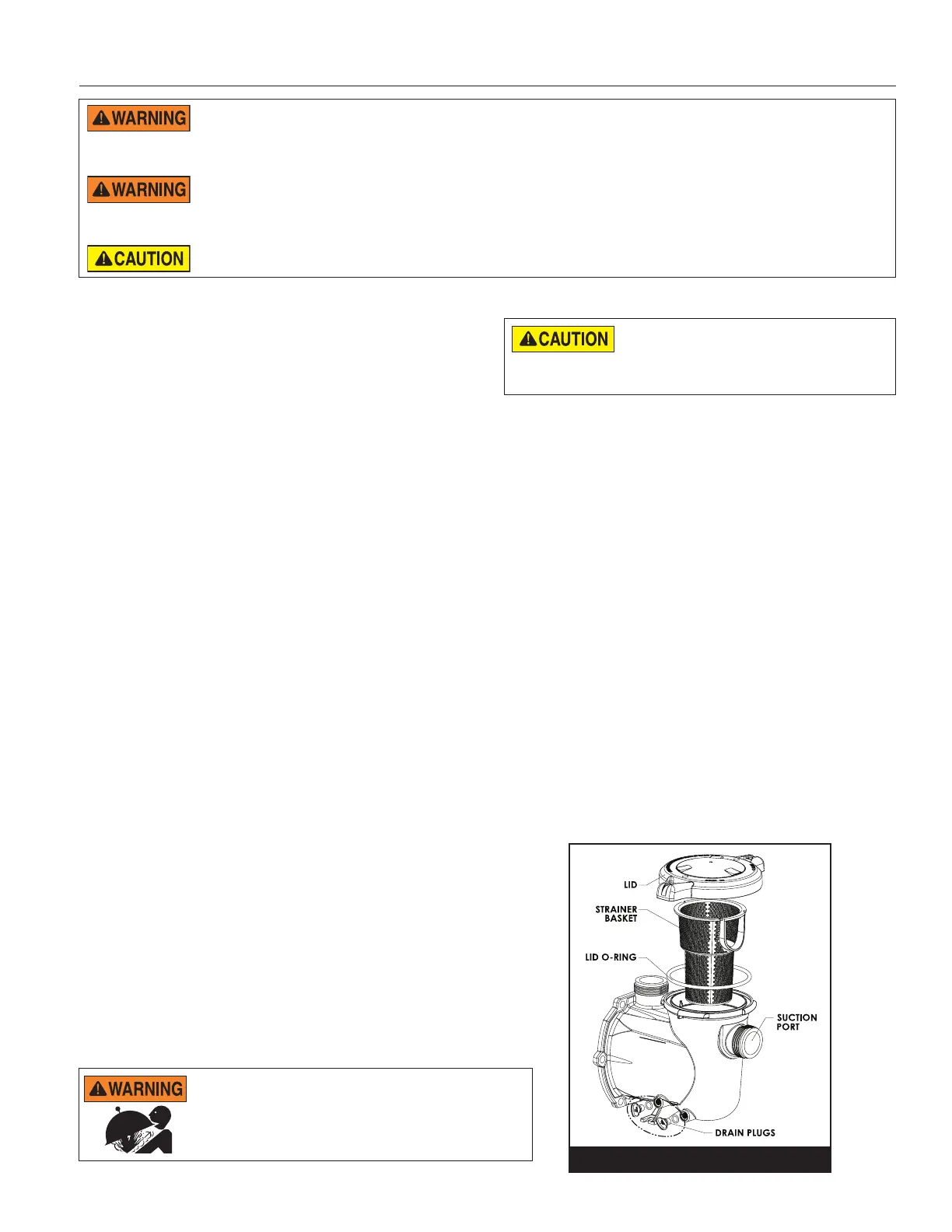

Cleaning the Pump Strainer Basket

The strainer pot is located at the front of the pump and

houses the pump strainer basket.

The strainer basket can be viewed through the strainer

pot lid and should be visually inspected at least once

a week. Regularly emptying and cleaning the strainer

basket will lead to higher lter and heater eciency and

prevent unnecessary stress on the pump motor.

TO CLEAN THE STRAINER BASKET:

1. Press ON/STOP to stop the pump and disconnect

all power to the pump at the circuit breaker.

2. Open the lter's air relief valve and relieve all

pressure from the ltration system.

3. Turn the strainer pot lid counter-clockwise and

remove it from the pump.

4. Remove the strainer basket and rinse out all debris.

Replace the basket if it is cracked or damaged.

5. Place the strainer basket back into the strainer pot.

Ensure the opening in the front of the strainer basket

is aligned with the suction outlet.

6. Fill the strainer pot up to the suction port with water.

7. Clean the lid O-ring and sealing surface of the

strainer pot.

Note: It is important to keep the lid O-ring clean.

8. Reinstall the lid by placing it onto the strainer pot

and tightening clockwise until the lid handles are

perpendicular to the suction port.

Note: Ensure the lid O-ring is properly placed and

is not being pinched between the lid and strainer

pot.

9. Open the lter air relief valve and stand clear of the

lter.

10. Reestablish power to the pump at the circuit breaker

and start the pump.

11. When a steady stream of water ows from the lter

air relief valve, close the valve.

Winterizing

Do NOT rely solely on Thermal Mode to protect

your ltration system from freezing temperatures.

Thermal Mode is based on the internal drive temperature and may not

reect actual air temperature.

You are responsible for determining when freezing

conditions may occur. If freezing conditions are

expected, take the following steps to reduce the risk of

freeze damage. Freeze damage is not covered under

warranty.

In mild climate areas, when temporary freezing

conditions may occur, run your ltering equipment all

night to prevent freezing.

TO PREVENT FREEZE DAMAGE:

1. Press ON/STOP to stop the pump and disconnect

all power to the pump at the circuit breaker.

2. Open the lter's air relief valve and relieve all

pressure from the ltration system.

3. Remove both drain plugs from the bottom of the

strainer pot and drain the pump. Store the plugs in

the strainer basket.

4. Cover the motor to protect it from severe rain, snow

and ice.

Note: Do not wrap motor with plastic or other air

tight materials during winter storage. Never cover

the motor when operating or expecting operation.

THIS SYSTEM OPERATES UNDER HIGH PRESSURE. When

any part of the circulating system is serviced, air can enter the

system and become pressurized. Pressurized air can cause the

lid to separate which can result in serious injury, death, or property

damage. To avoid this potential hazard, follow above instructions.

Always disconnect power to the pump at the circuit breaker and relieve pressure in the ltration system before servicing the pump. Failure

to do so could result in death or serious injury to serviceman, pool users or others due to electric shock. Do NOT attempt to adjust or

service without consulting your dealer or a qualied pool technician. Read the entire Installation and Maintenance Guide before attempting to use, service, or

adjust the pool ltering system or heater.

Do NOT open the pump strainer pot if pump fails to prime or if pump has been operating without water in the strainer pot. Pumps operated

in these circumstances may experience a build up of vapor pressure and may contain scalding hot water. Opening the pump may cause

serious personal injury. In order to avoid the possibility of personal injury, ensure the suction and return valves are open and strainer pot temperature is cool

to touch, then open with extreme caution.

To prevent damage to the pump and for proper operation of the system, clean pump strainer and skimmer baskets regularly.

STRAINER POT ASSEMBLY

Loading...

Loading...