18

INTELLIFLO3™ VSF / INTELLIPRO3™ VSF Variable Speed and Flow Pump Installation and Maintenance Guide

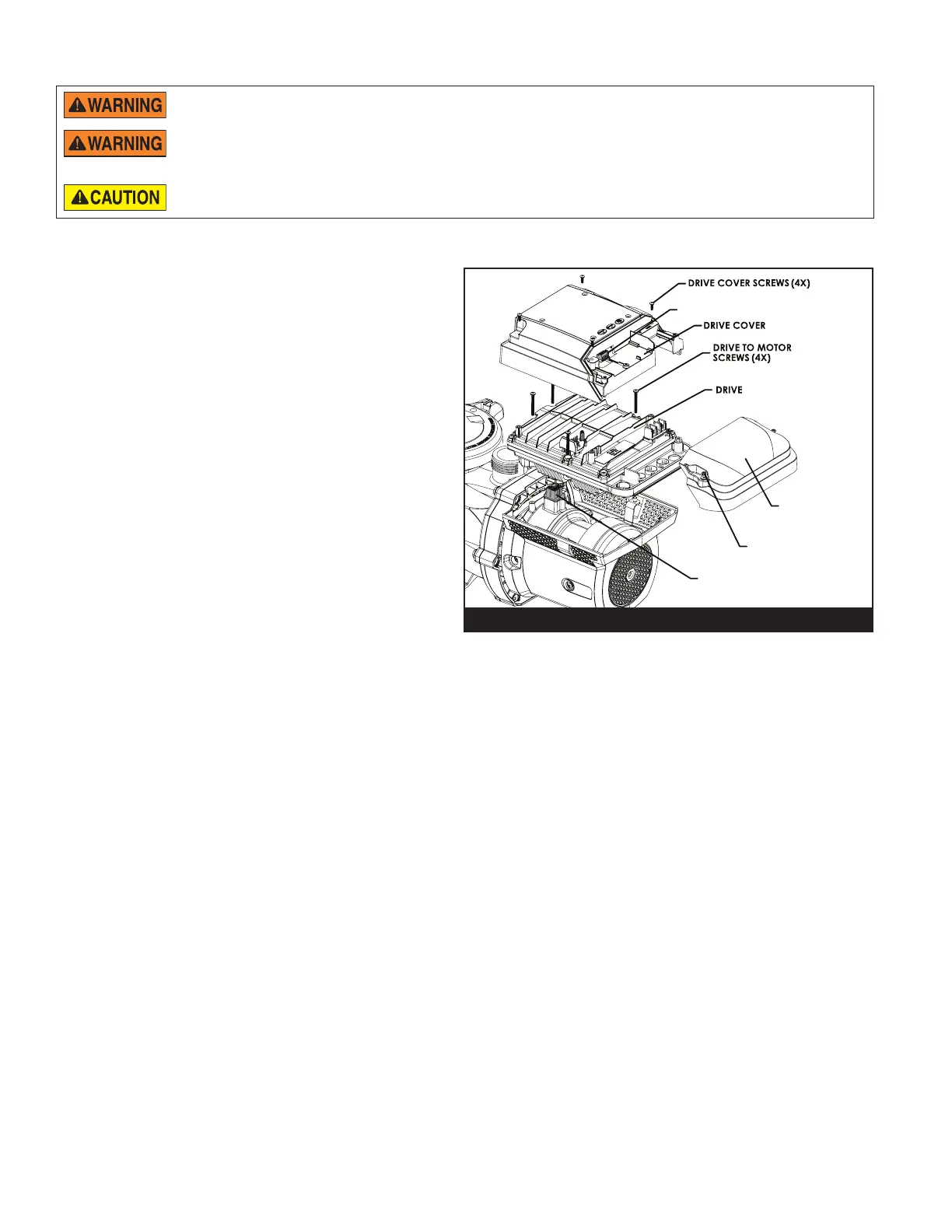

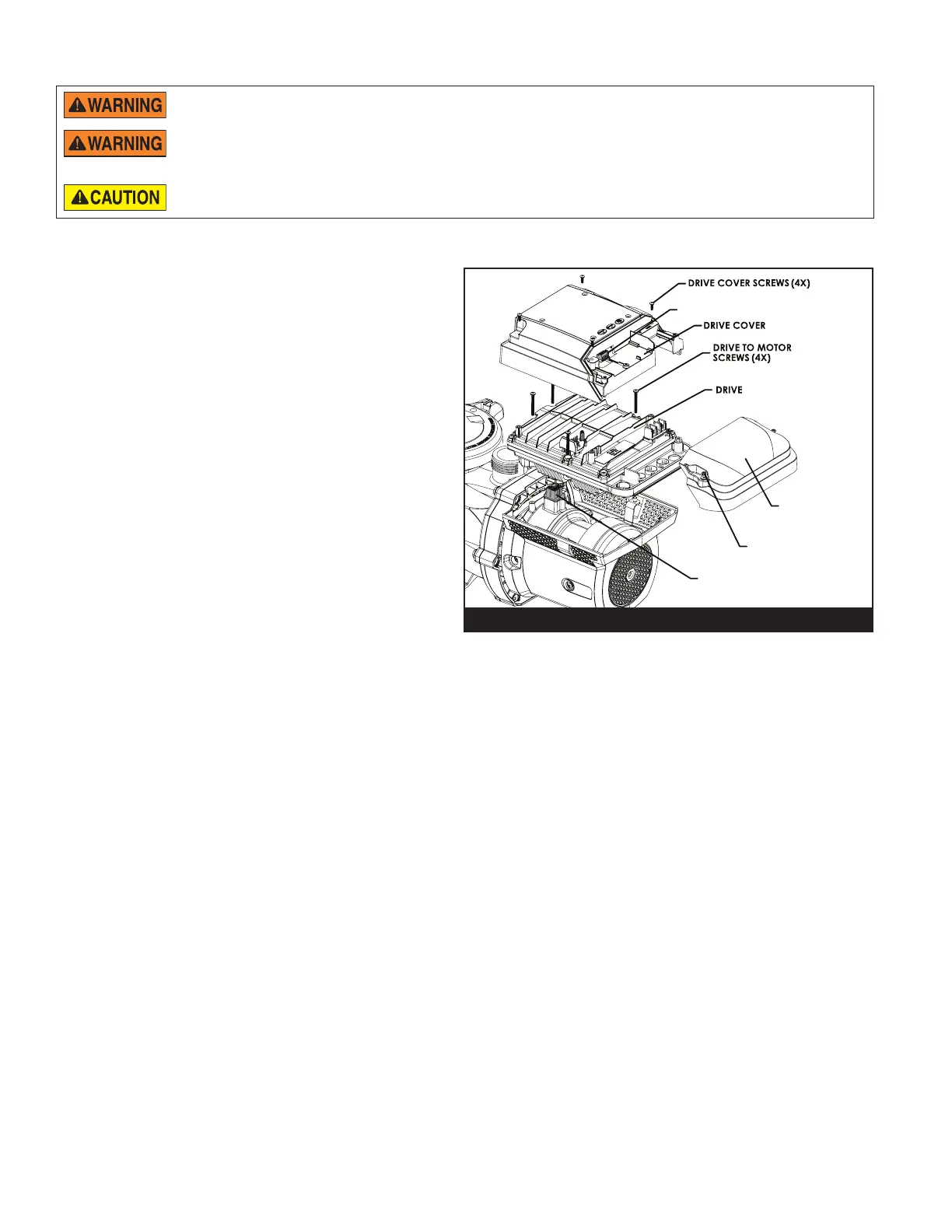

Drive Removal and Installation

TO DISASSEMBLE AND REMOVE THE DRIVE:

1. Press ON/STOP to stop the pump and

disconnect all power to the pump at the circuit

breaker.

2. Loosen the two captive Phillips-head Wiring

Cover Screws. Remove the Wiring Cover from

the Drive.

3. Disconnect main power wiring and remove the

Automation Terminal Blocks from the drive.

4. Remove the four Phillips-head Drive Cover

Screws. Remove the Drive Cover from the

Drive.

5. Remove the four Phillips-head Drive-to-Motor

Screws.

6. Gently separate the Drive from the Motor/

Hydraulic Assembly and place it aside.

TO INSTALL THE DRIVE:

1. Ensure the drive connection gasket is not

damaged and is in place.

Do not reassemble with a damaged or missing

gasket. Replace the gasket if damaged.

2. Align the Drive with the Drive Connection and seat the drive onto the motor.

3. Secure the Drive to the motor with the four Drive to Motor Screws.

4. Reinstall the Drive Cover and secure it with the four Drive Cover Screws.

5. Rewire automation and power cables that were disconnected during drive removal. Refer to Electrical Installation,

page 3 and Connecting to an Automation System, page 4.

6. Reinstall the Wiring Cover and secure it with the two Wiring Cover Screws.

Relocating the WiFi Antenna

The pump communicates wirelessly via a Bluetooth

®

Wireless Technology connection with your personal device, or a

2.4ghz WiFi connection with your home router.

The drive's WiFi antenna features a male SMA bulkhead connector on the outside of the top cover and can be

removed by loosening the antenna connector.

An SMA extension cable can be used to remotely mount the antenna in an area where it can receive a better signal.

An extension cable is only recommended in order to relocate the antenna to a more favourable location; such as

outside of a masonry enclosure or around the corner of a building. In most other cases using an extension cable will

harm the signal.

To avoid dangerous or fatal electrical shock hazard, switch OFF power to motor before working on pump or motor.

FIRE AND BURN HAZARD. The pump motor may run at high temperatures. To reduce the risk of re, do NOT allow leaves, debris, or

foreign matter to collect around the pump motor. To avoid burns when handling the motor, shut off the motor and allow it to cool for 20

minutes before servicing. The pump provides an automatic internal cutoff switch to protect the motor from heat damage during operation.

To avoid electrical hazard, do NOT remove the four torx-head screws from the drive.

DRIVE COMPONENTS

WIRING COVER

SCREWS (2X)

WIRING COVER

DRIVE CONNECTION

RS-485 TERMINAL BLOCK

Loading...

Loading...