Adjustment

37

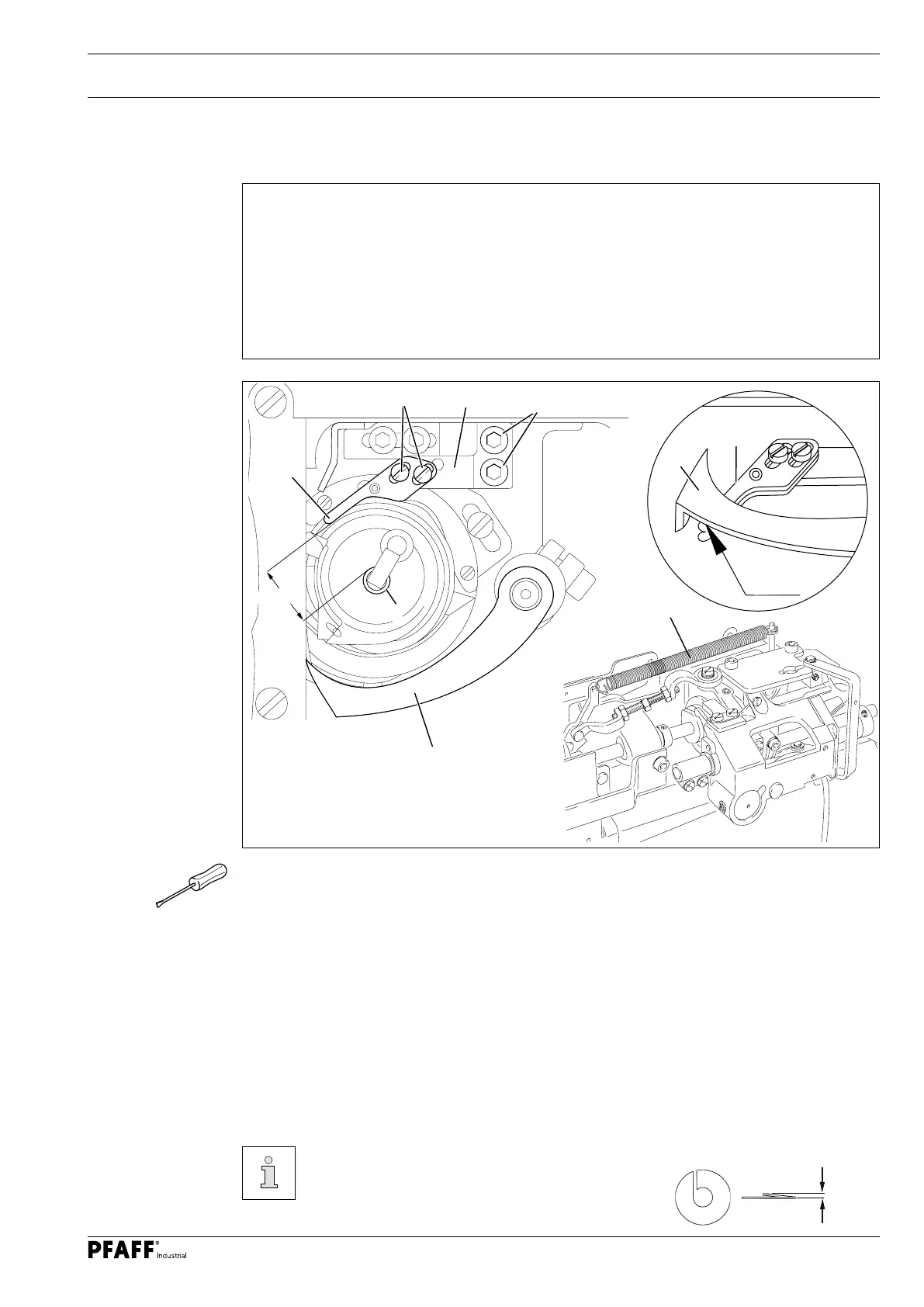

Fig. 13 - 32

13.05.14 Bobbin thread clamp spring (make this adjustment on both clamp springs with

the PFAFF 1244)

Rule

1. There should be a clearance of 0.3 mm between the clamp spring 5 and the under-

side of the thread catcher 4.

2. The tips of the clamp spring 5 should be flush with the back edge of the thread

catcher 4 when the thread catcher 4 is in the front turning point ( see arrow ).

3. There should be a clearance of approx. 12 mm between the inner edge of the clamp

spring 5 and the guide bushing 7.

4. It should be easy to insert and remove the bobbin case from the hook.

O Align the bracket 1 ( screws 2 ) so that it is parallel to the machine bed plate and is

positioned in the centre of its range.

O Remove the spring 3.

O Swivel the thread catcher 4 by hand over the clamp spring 5.

O Bend the clamp spring 5 according to rule 1.

O Insert the spring 3.

O Move the machine to the needle rise position, activate the engaging lever and move the

thread catcher to its front turning point by turning the handwheel.

O Align the clamp spring 5 ( screws 6 ) - and the bracket 1 ( screws 2 ) if necessary in the

elongated hole - according to rules 2 and 3.

O Tighten the screws 2 and 6 in this position, ensuring that the bracket 1 is still parallel to

the machine bed plate.

Check the height of the spring below the bobbin in the hook if you have sewing

problems after trimming the thread!

The height of the spring should be approx. 1 mm.

1

2

3

7

0.3 mm

12 mm

4

5

5

4

6

1 mm

Loading...

Loading...