34

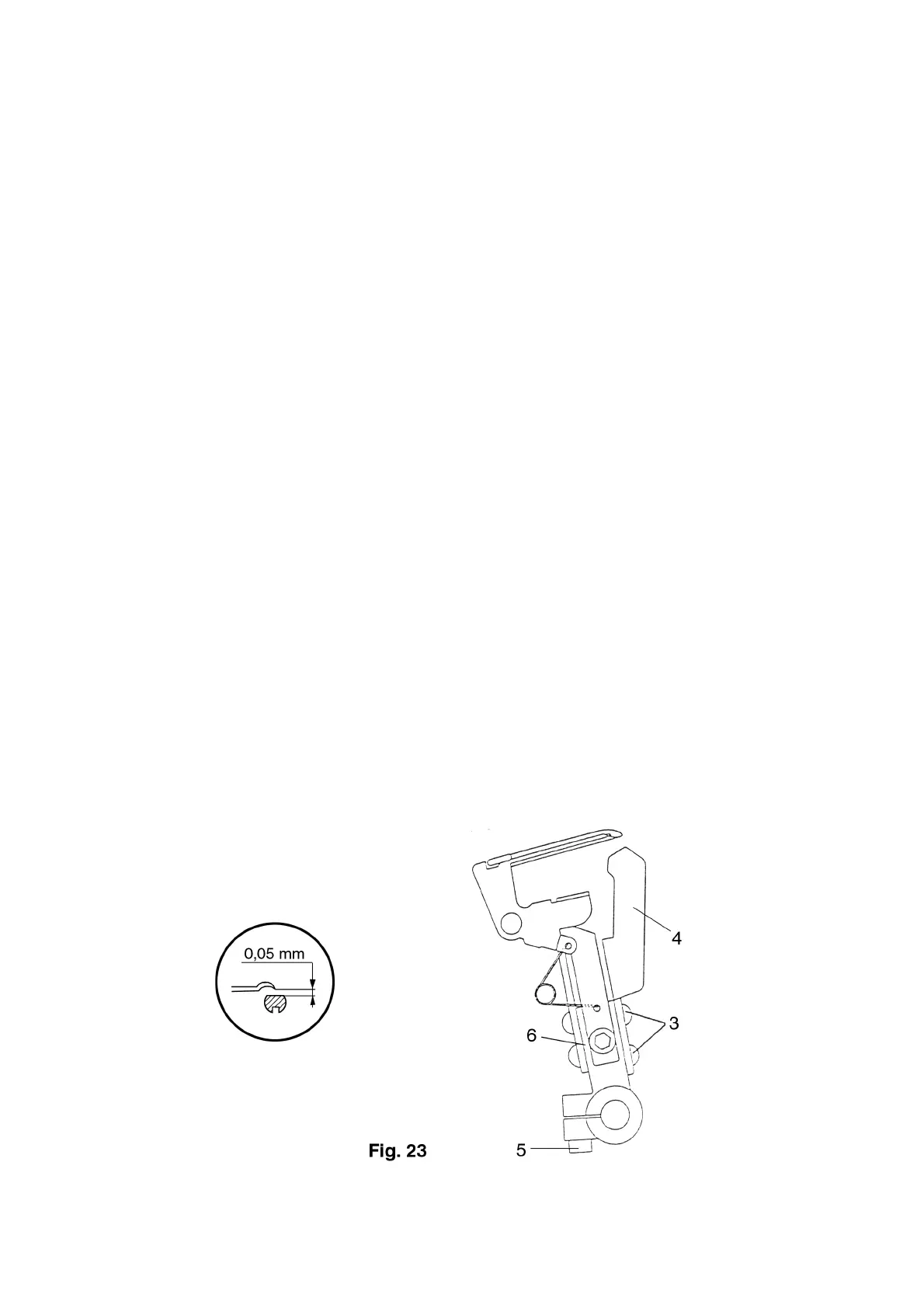

12. Setting the looper-to-needle clearance

Requirement:

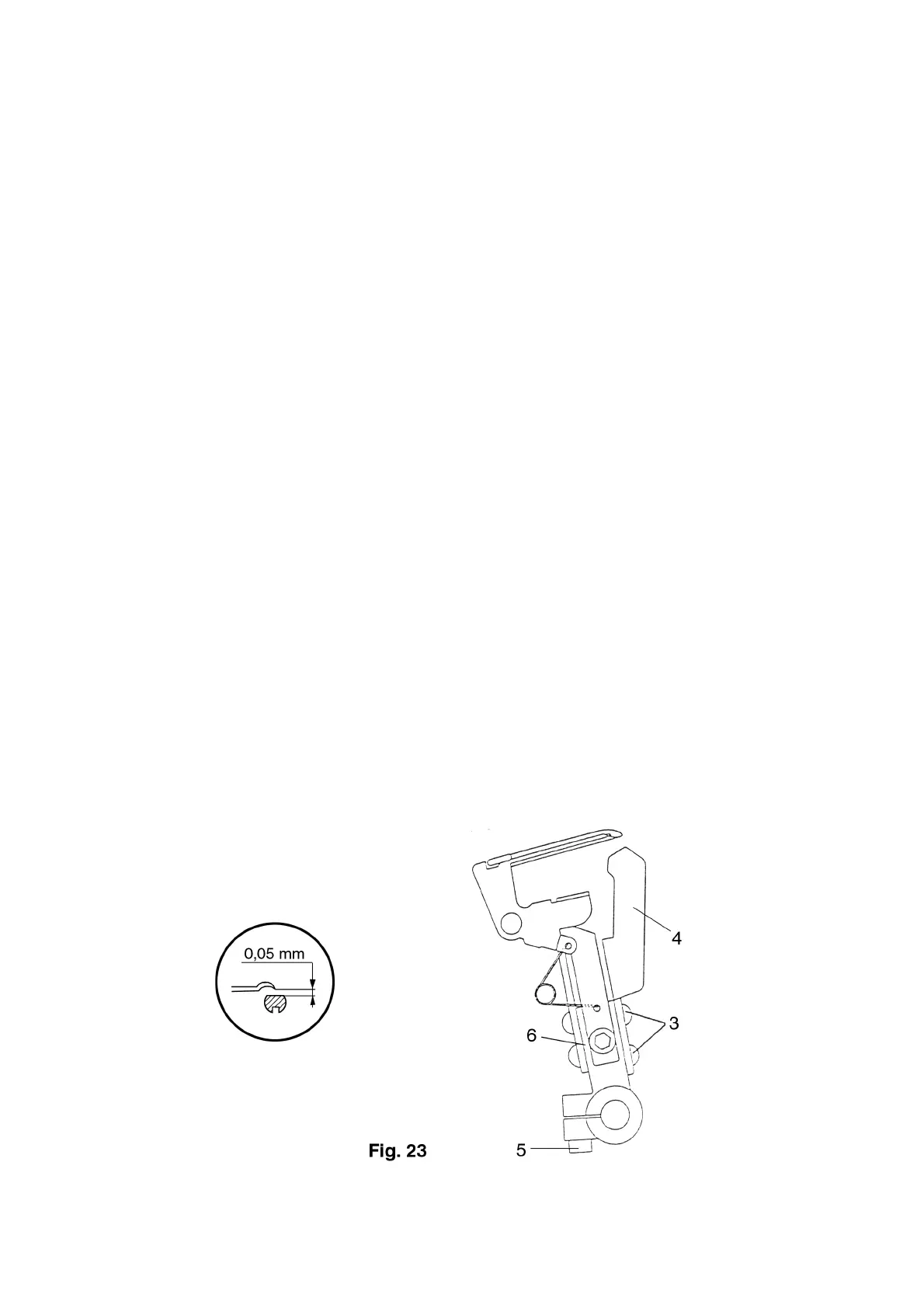

When the looper point is in the scarf of the needle while moving to the right, the looper-to-needle clearan-

ce must be 0 - 0.05 mm (fig. 23).

Note:

A new needle system ELx705 Nm 90 must be used for the following steps.

Check:

● Remove the presser foot and the needle plate.

● Slightly loosen both fastening screws 3 and push the needle guard 4 slightly toward the rear.

● Turn the handwheel in the normal direction until the looper point is exactly in the scarf of the needle,

while moving to the right.

● Check the clearance between the point of the looper and the needle.

Setting:

● Turn the handwheel in the normal direction until the looper point, when moving to the right, is positio-

ned exactly in the scarf of the needle “R1”.

● Loosen the screw 5 on the looper lever 6.

● Set the looper-to-needle clearance by moving the looper lever 6.

● Tighten screw 5.

Test:

● As described under “Requirement”.

Loading...

Loading...