46

Setting the needle guards

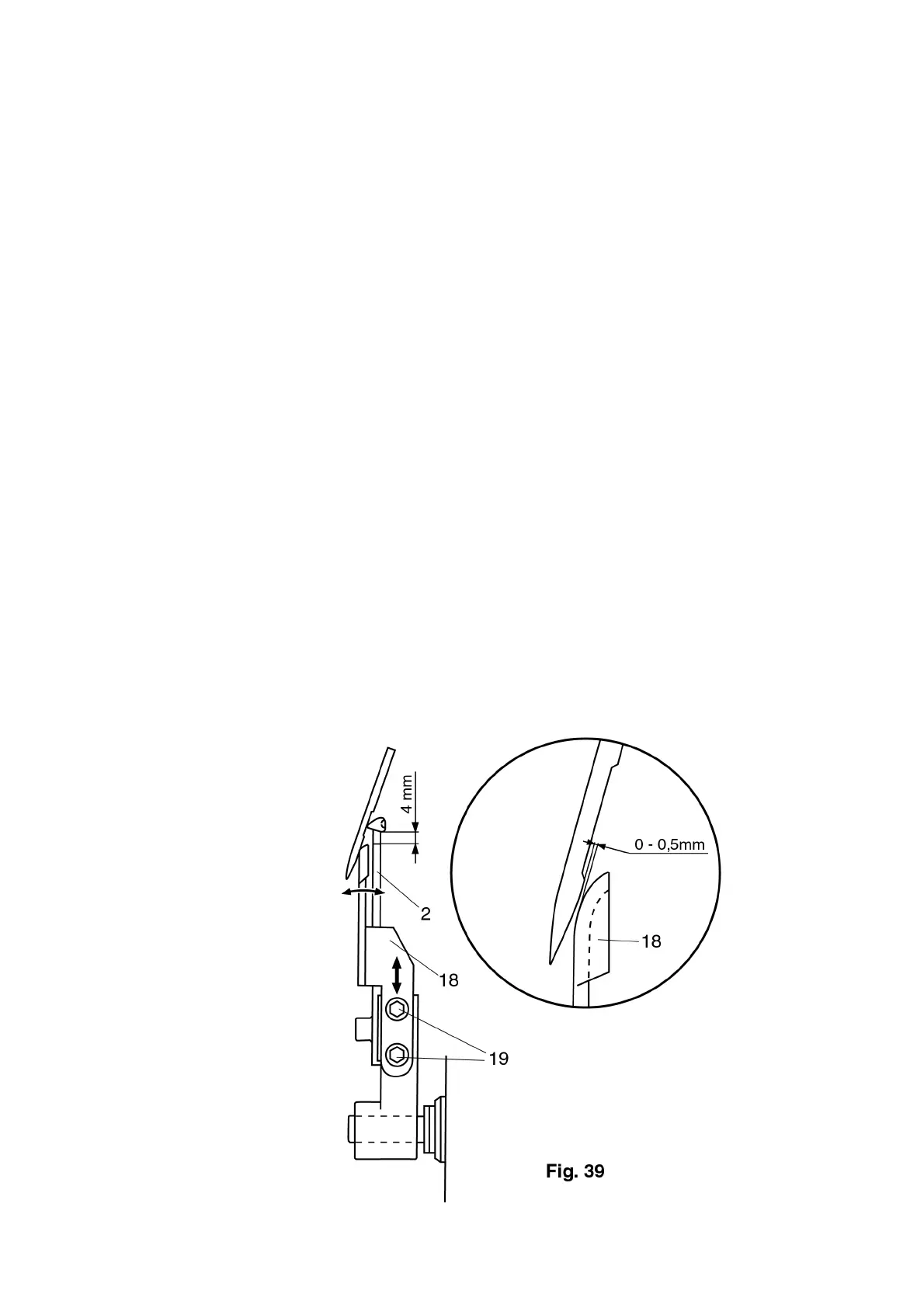

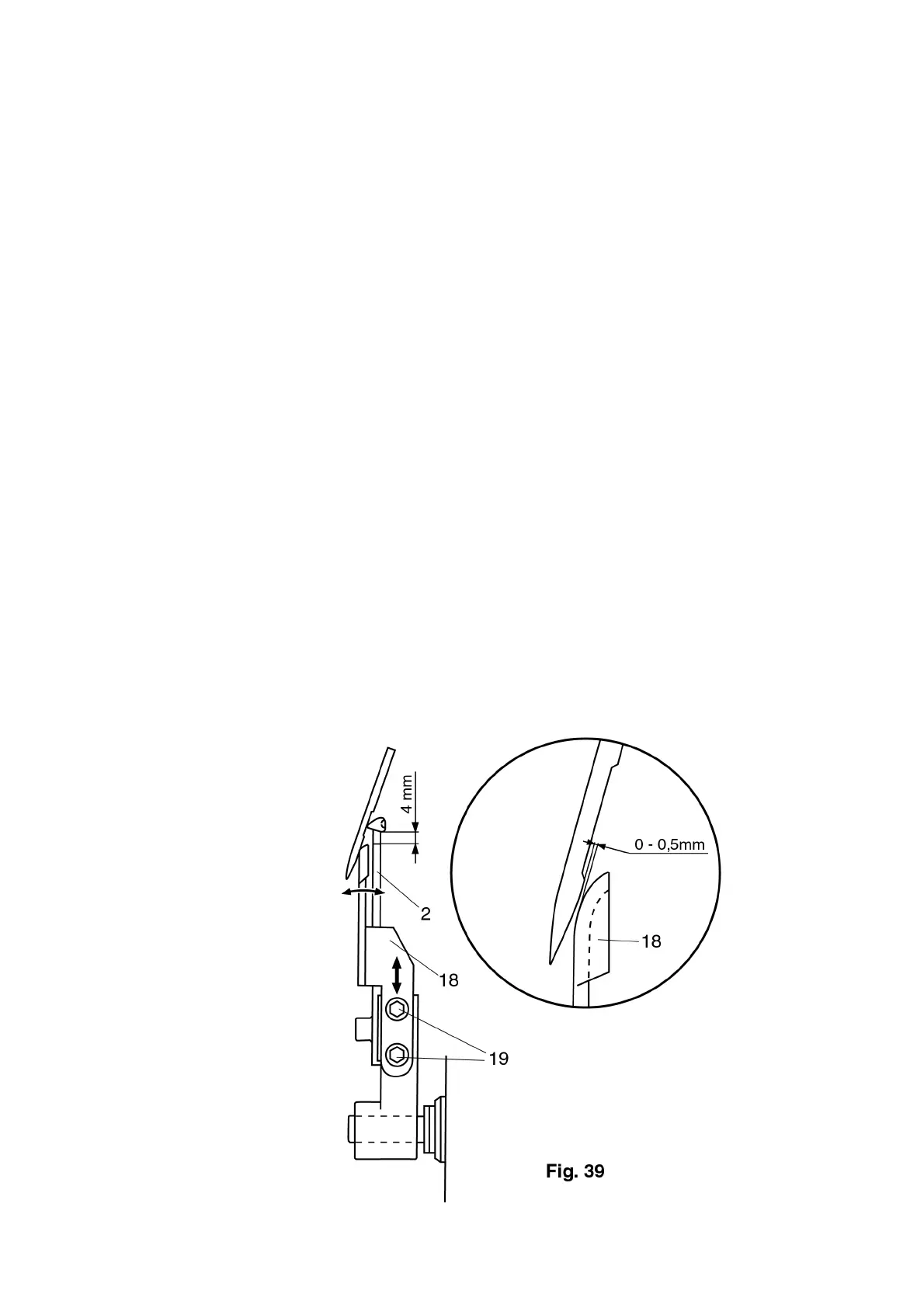

21. Setting the rear needle guard

When the looper point of the lower overedge looper 2 is exactly at the center line of either needle “R1” or

needle “R2” when moving to the right, the needles should have a clearance of 0 - 0.05 mm to the needle

guard 18 (fig. 39).

Check:

● Turn the handwheel in the normal direction until the looper point, when moving to the right, is precisely

behind either needle “R1” or “R2”.

● Check the distance.

Setting:

● Turn the handwheel in the normal direction until the looper point, when moving to the right, is precisely

behind either needle “R1” or “R2”.

● Slightly loosen the screws 19.

● Push the rear needle guard 18 so that the clearance, as seen in fig. 39, is set.

● Tighten the screws 19.

Test:

● As described under “Requirement”.

Loading...

Loading...