36

Setting the upper overedge looper

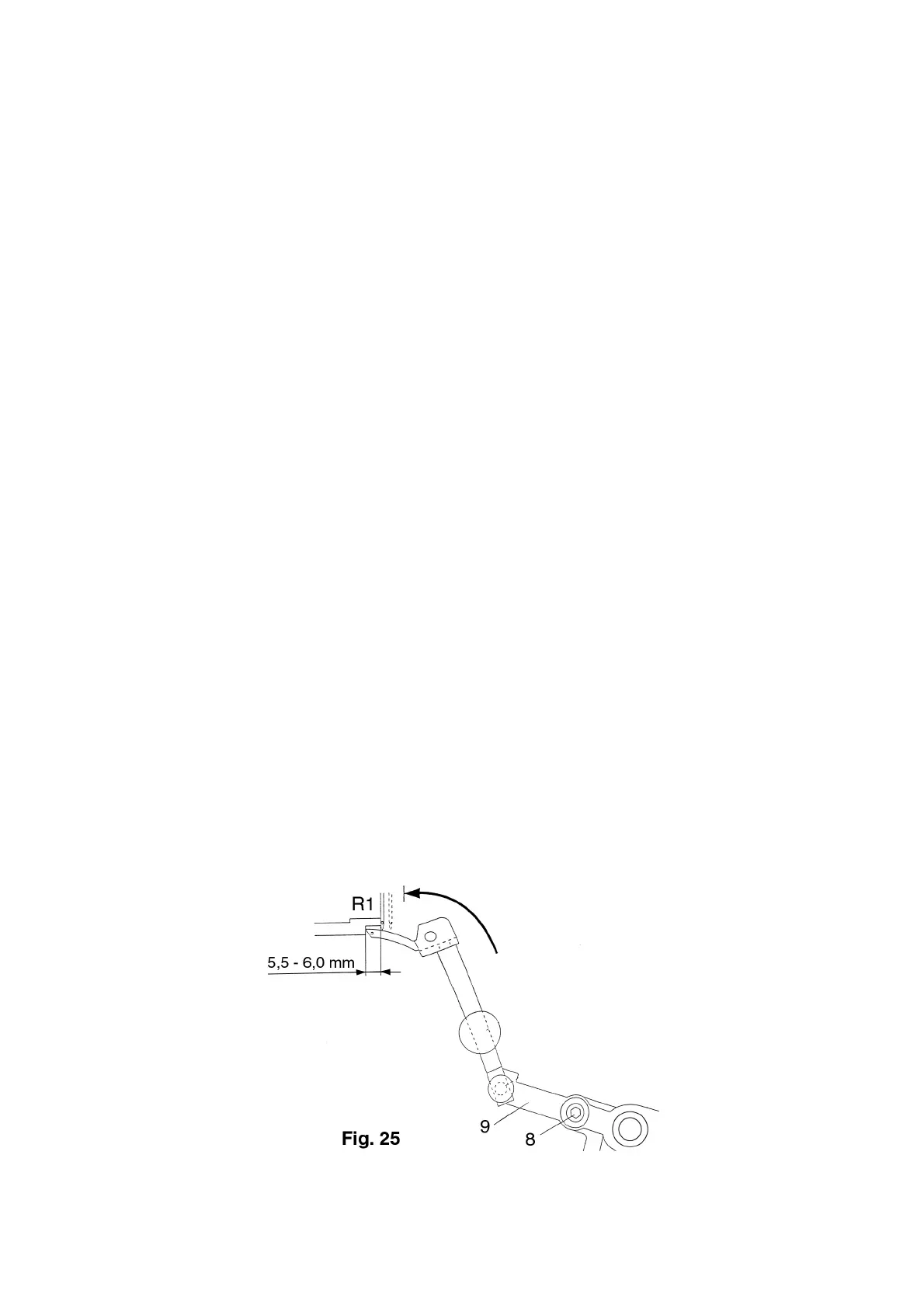

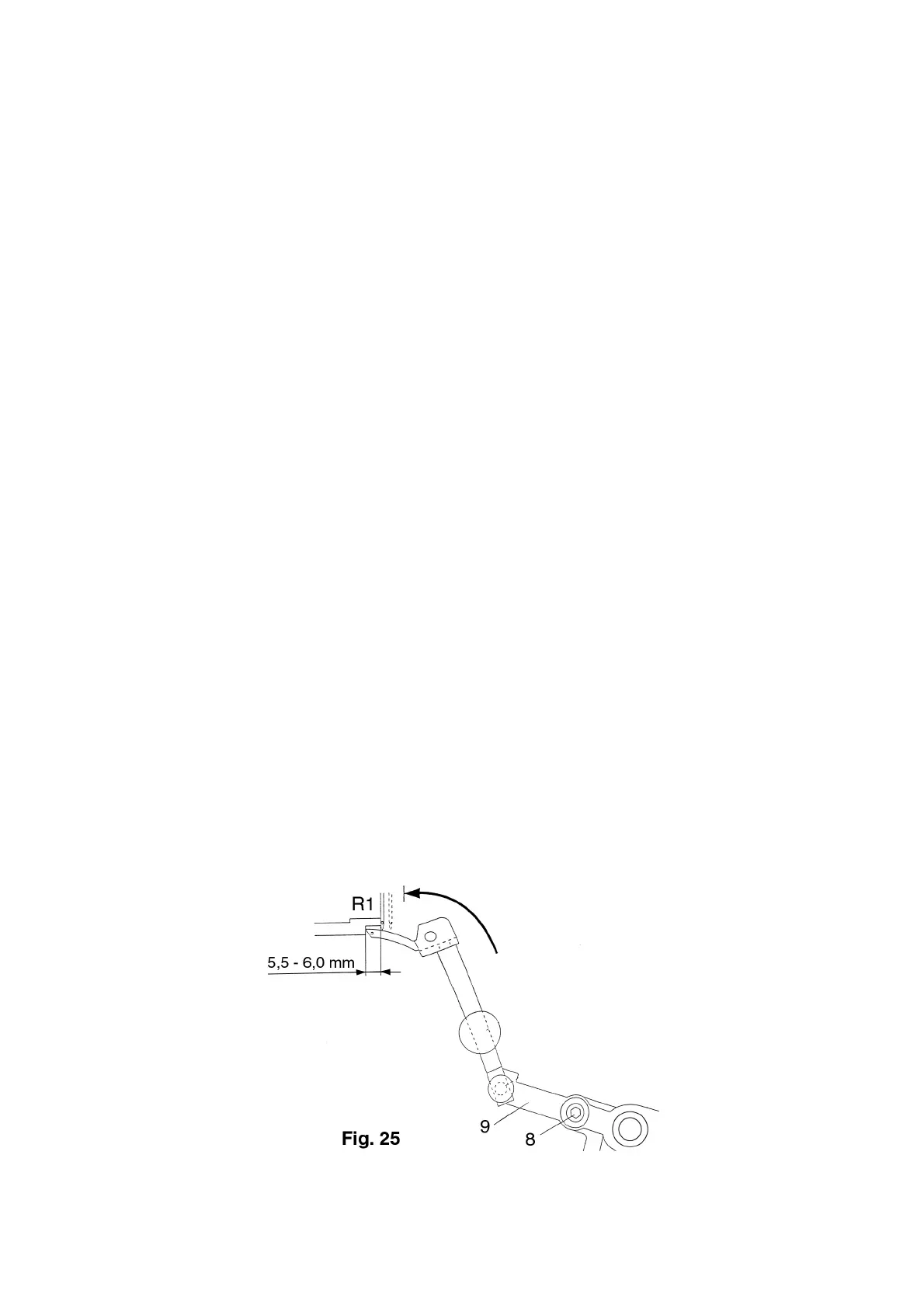

14. Setting the lateral clearance to the left needle

Requirement:

When the upper overedge looper is at its left point of reversal, the clearance of looper point to the left

needle must be 5.5 - 6.0 mm (fig. 25).

Note:

The rock shaft and its guide bushes must not have any axial play.

Check:

● Turn the handwheel in the normal direction until the upper looper is at its left point of reversal.

● Check the clearance using the adjustment gauge (measurement C).

Setting:

● Turn the handwheel in the normal direction until the upper looper is at its left point of reversal.

● Slightly loosen fastening screw 8.

● Move the looper drive arm 9 until the clearance between the looper point and the left needle is 5.5 -

6.0 mm.

● Tighten fastening screw 8.

Test:

● As described under “Requirement”.

● Check that the machine runs freely.

Loading...

Loading...