49

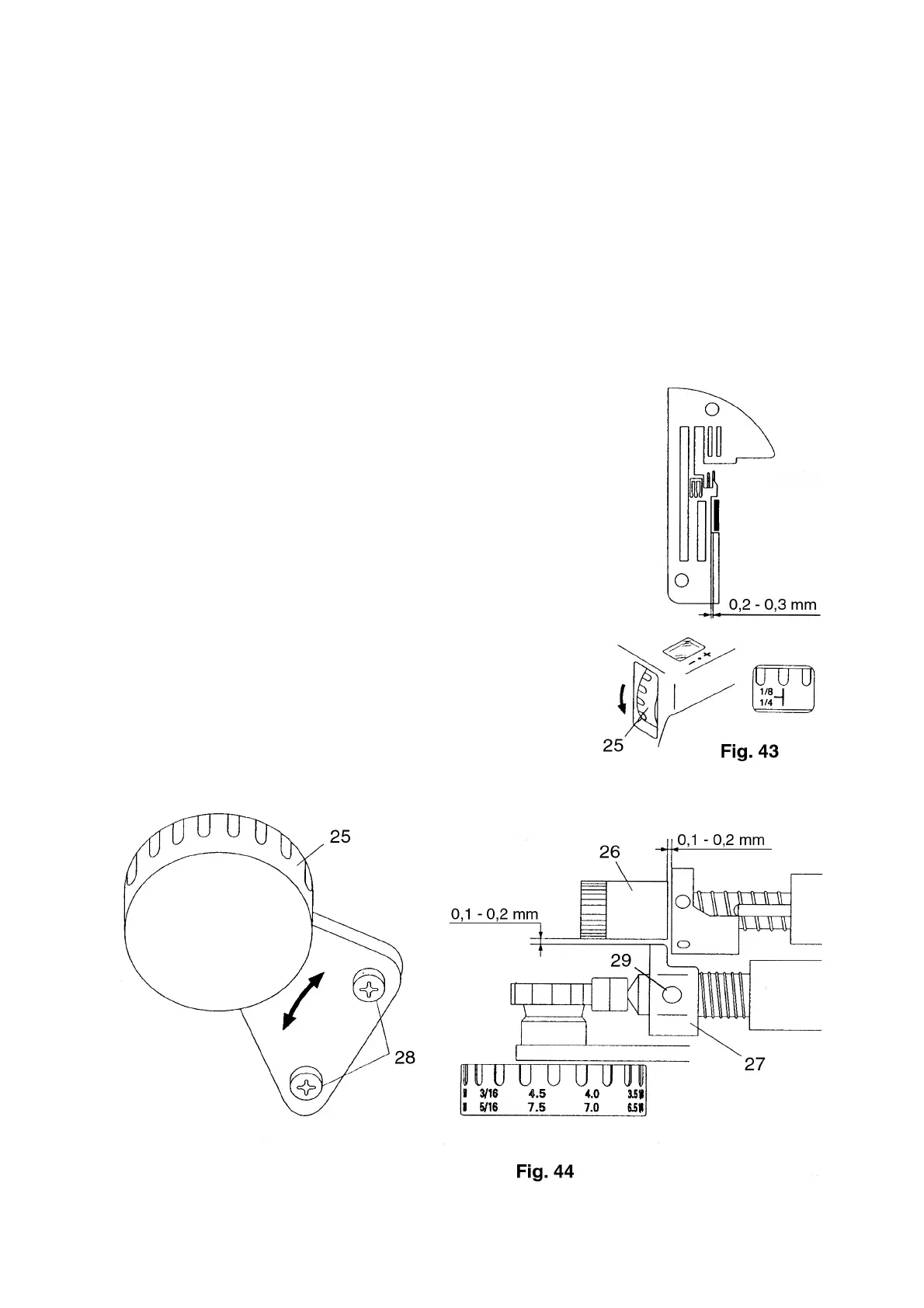

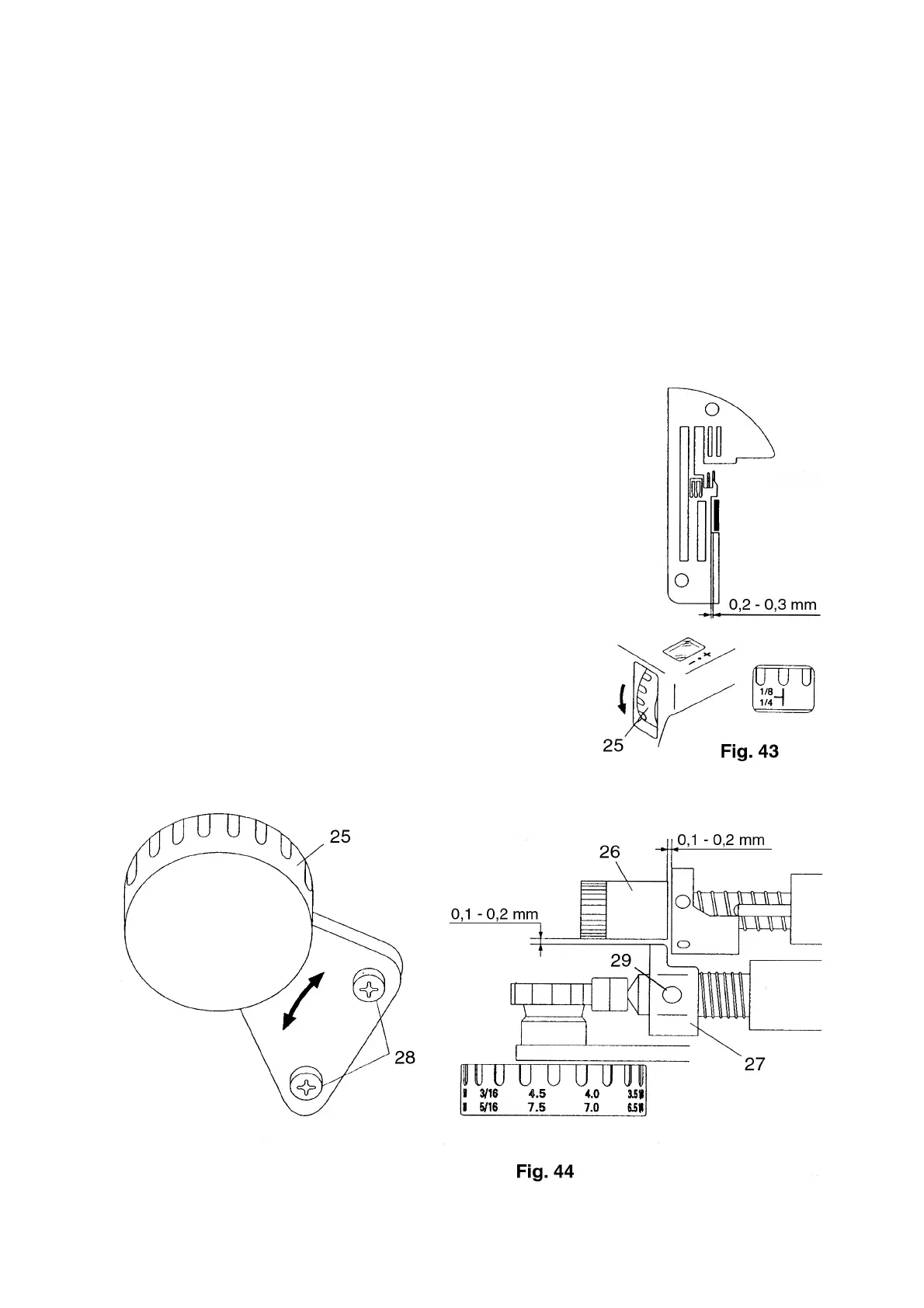

24. Setting the lower blade bracket and the seam width adjusting knob

Requirement:

When the seam width adjusting knob 25 is set at the lowest number (fig. 43), the lower blade must have a

clearance of 0.2 - 0.3 mm to the needle plate. The knob 26 of the upper blade must also have a clearance

of 0.1 - 0.2 mm to the holder 27 (fig. 44).

Check:

● Set the seam width adjusting knob 25 to the narrowest seam width.

● Carry out a visual check (fig. 43).

Setting:

● Set the seam width adjusting knob 25 to the narrowest seam width.

● Loosen the fastening screws 28.

● Push the complete seam width adjusting knob 25 so that a

clearance of 0.2 - 0.3 mm to the needle plate is set.

● Tighten the fastening screws 28.

● Loosen the fastening screw 29 (fig. 44).

● Push the holder 27 toward the front until the holder 27 has a

clearance of 0.1 - 0.2 mm to the knob 26 of the upper blade.

● Tighten the fastening screw 29.

Test:

● As described under “Check”.

Loading...

Loading...