9.11

BRAKES

9

8. Clean the caliper body, piston, and retaining bracket with

brake cleaner or alcohol.

NOTE: Be sure to clean seal grooves in caliper

body.

Caliper Inspection

1. Inspect caliper body for nicks, scratches, pitting or wear.

Measure bore size and compare to specifications. Replace

if damaged or worn beyond service limit.

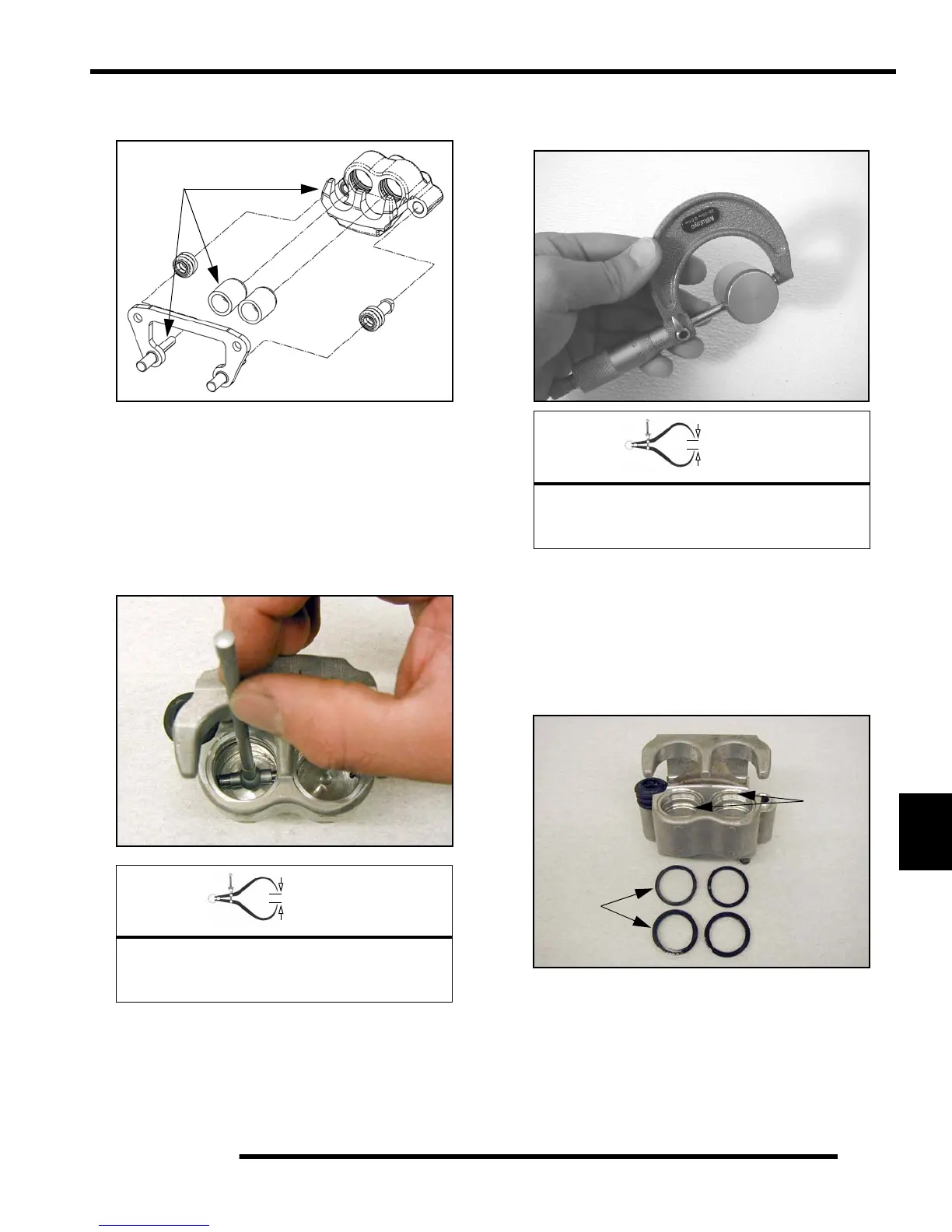

2. Inspect piston for nicks, scratches, pitting or wear. Measure

piston diameter and replace if damaged or worn beyond

service limit.

3. Inspect the brake disc and pads as outlined in this chapter.

Caliper Assembly

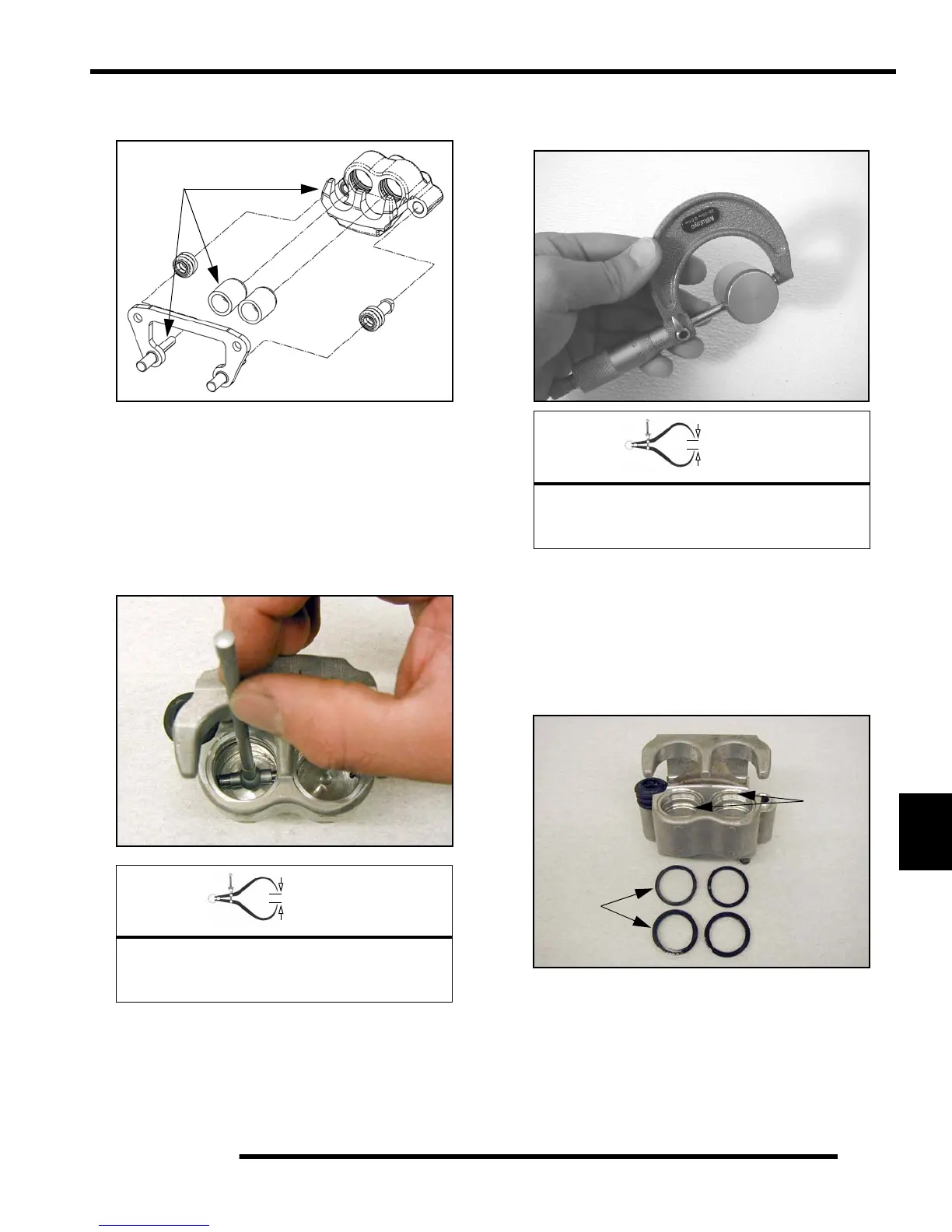

1. Install new O-rings in the caliper body. Be sure the

grooves are clean and free of residue or brakes may drag

upon assembly.

2. Coat pistons with clean Polaris DOT 4 Brake Fluid. Install

pistons with a twisting motion while pushing inward.

Piston should slide in and out of bore smoothly, with light

resistance.

= In. / mm.

Caliper Piston Bore I.D.:

Std: 1.004” (25.5 mm)

Service Limit: 1.006” (25.55 mm)

Clean

Components

= In. / mm.

Caliper Piston O.D.:

Std: 1.002” (25.45 mm)

Service Limit: 1.000” (25.4 mm)

New

Seal

Grooves

O-Rings

Loading...

Loading...