9.19

BRAKES

9

REAR BRAKE DISC

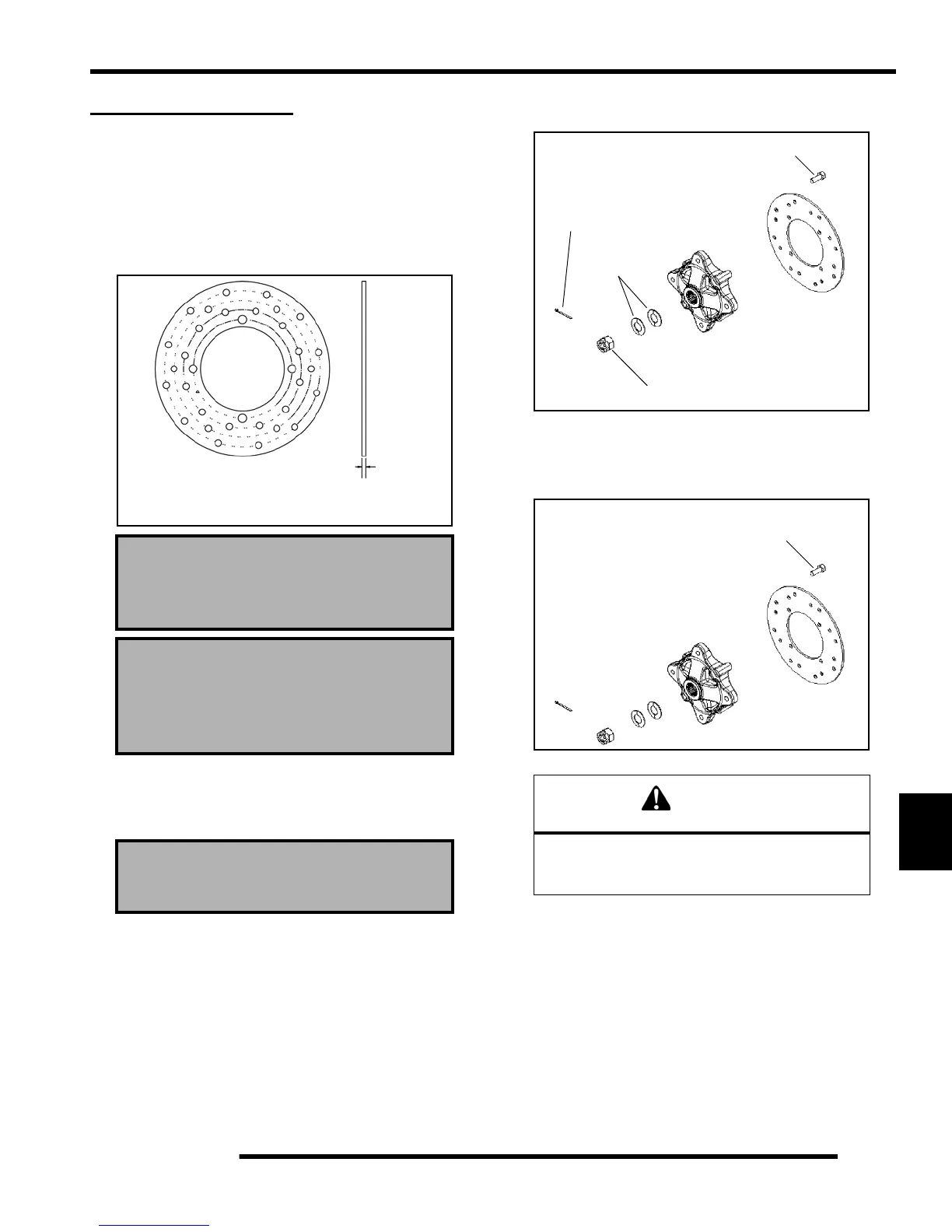

Disc Inspection

1. Visually inspect disc for scoring, scratches, or gouges.

Replace the disc if any deep scratches are evident.

2. Use a 0-1” micrometer and measure the disc thickness at

eight different points around the pad contact surface.

Replace disc if worn beyond service limit.

3. Mount a dial indicator and measure disc runout. Slowly

rotate the disc and read total runout on the dial indicator.

Replace the disc if runout exceeds specifications.

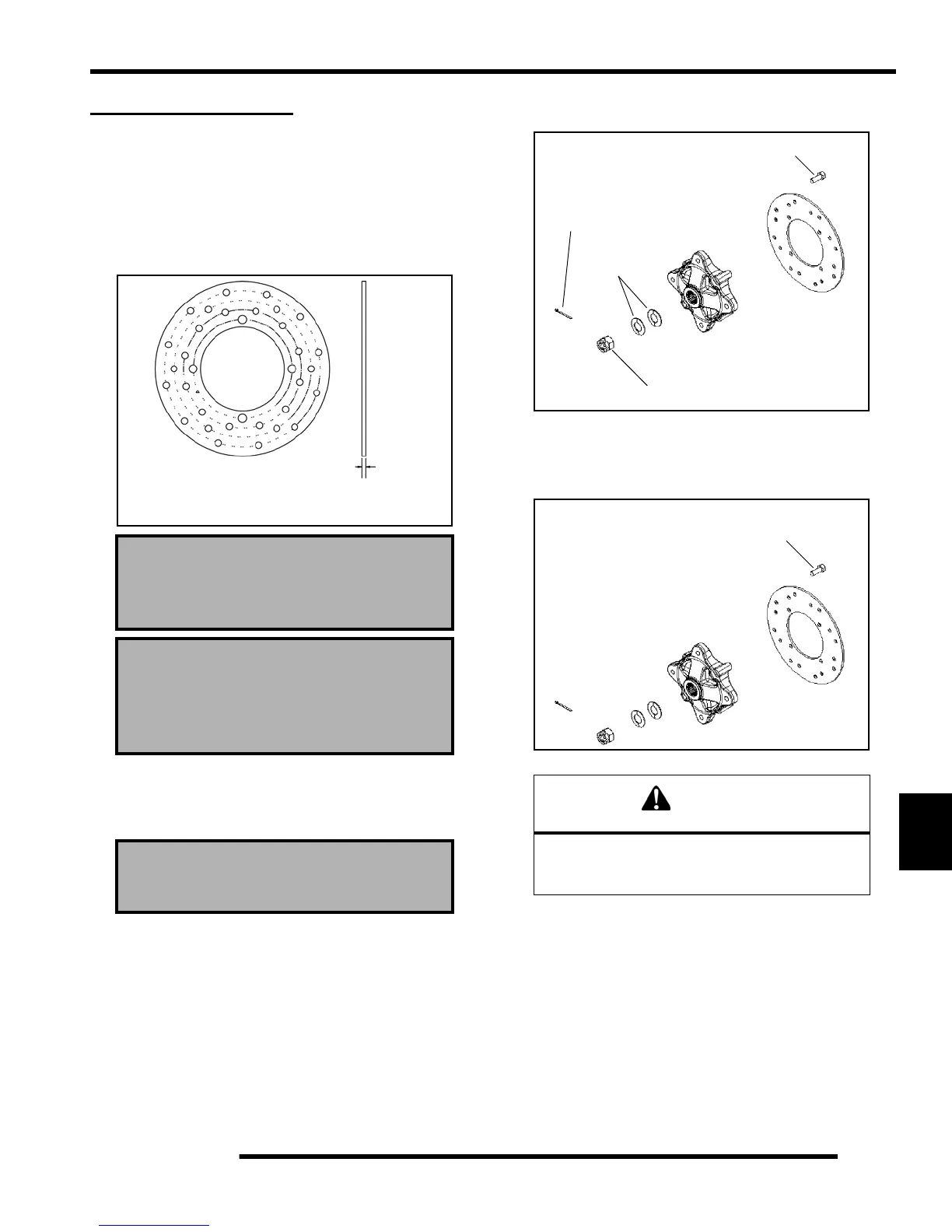

Disc Replacement

1. Remove rear brake caliper (see “REAR CALIPER

SERVICE”).

2. Remove wheel hub cotter pin, castle nut and washers.

3. Remove the hub assembly from the vehicle and remove the

(4) bolts retaining the disc to the hub.

4. Clean the wheel hub mating surface and install new disc on

wheel hub.

5. Install new bolts and torque to 28 ft. lbs. (38 Nm).

6. Install wheel hub assembly, washers, and castle nut.

Torque castle nut to 80 ft. lbs. (108 Nm) and install a new

cotter pin.

7. Install rear brake caliper (see “REAR CALIPER

SERVICE”). Follow the bleeding procedure outlined

earlier in this chapter.

8. Field test unit for proper braking action before putting into

service. Inspect for fluid leaks and firm brakes. Make sure

the brake is not dragging when pedal is released. If the brake

drags, re-check assembly and installation.

Brake Disc Thickness

New: .188” (4.76 mm)

Service Limit: .170” (4.32 mm)

Brake Disc Thickness Variance

Service Limit .002” (.051 mm)

difference between measurements

Brake Disc Runout

Service Limit .010” (.254 mm)

Measure

Thickness

Front

View

Side

View

CAUTION

Always use new brake disc mounting bolts. The

bolts have a pre-applied locking agent which is

destroyed upon removal.

Cotter

Pin

Washers

Nut

(4) Bolts

28 ft. lbs.

(38 Nm)

Loading...

Loading...