10.32

ELECTRICAL

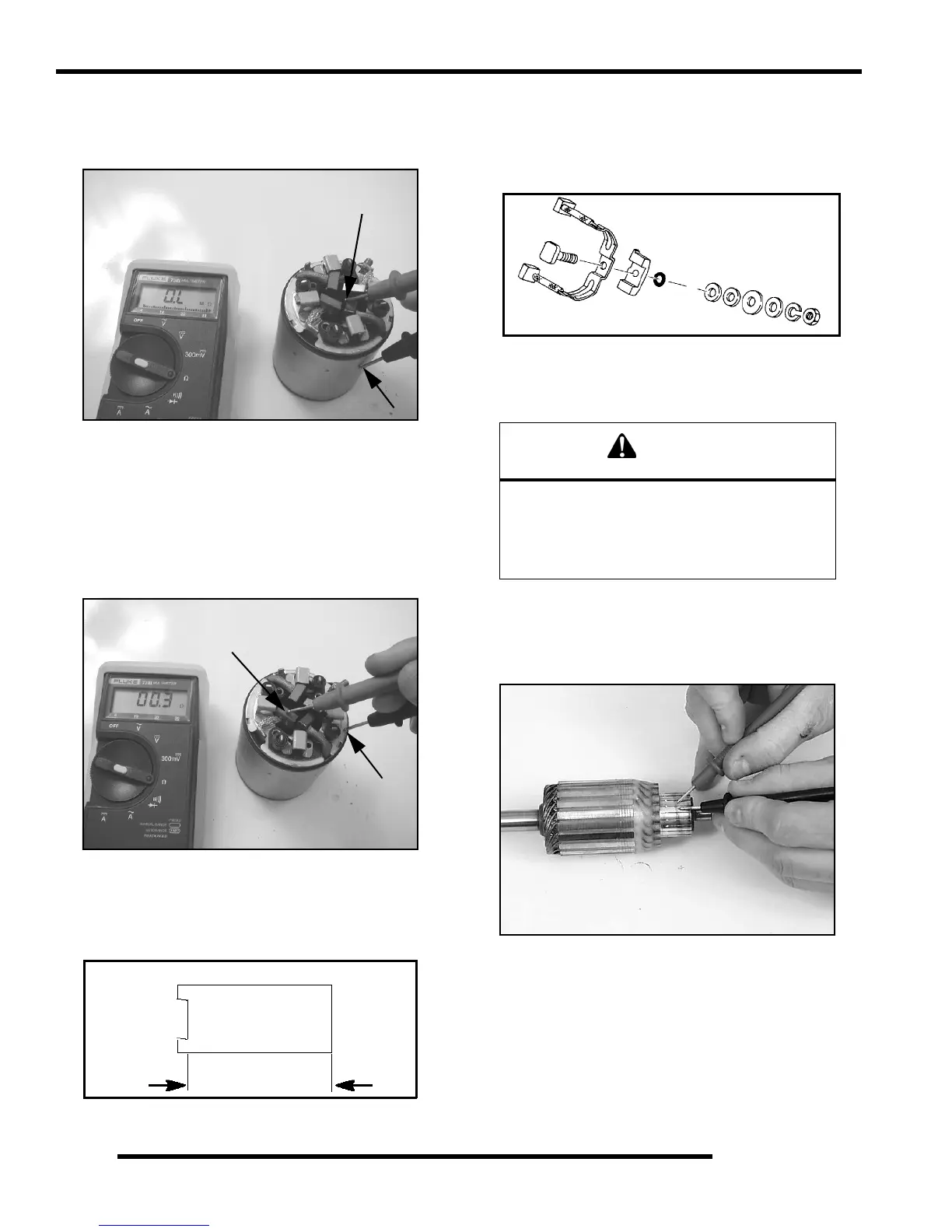

2. Measure resistance between insulated brush and starter

housing. Reading should be infinite (OL). Inspect

insulation on brush wires for damage and repair or replace

as necessary.

3. Slide positive brush springs to the side, pull brushes out of

their guides and remove brush plate. Slide brush end frame

off end of starter.

NOTE: The electrical input post must stay with the

field coil housing.

4. Measure resistance between ground brush and brush plate.

Resistance should be .3 ohms or less.

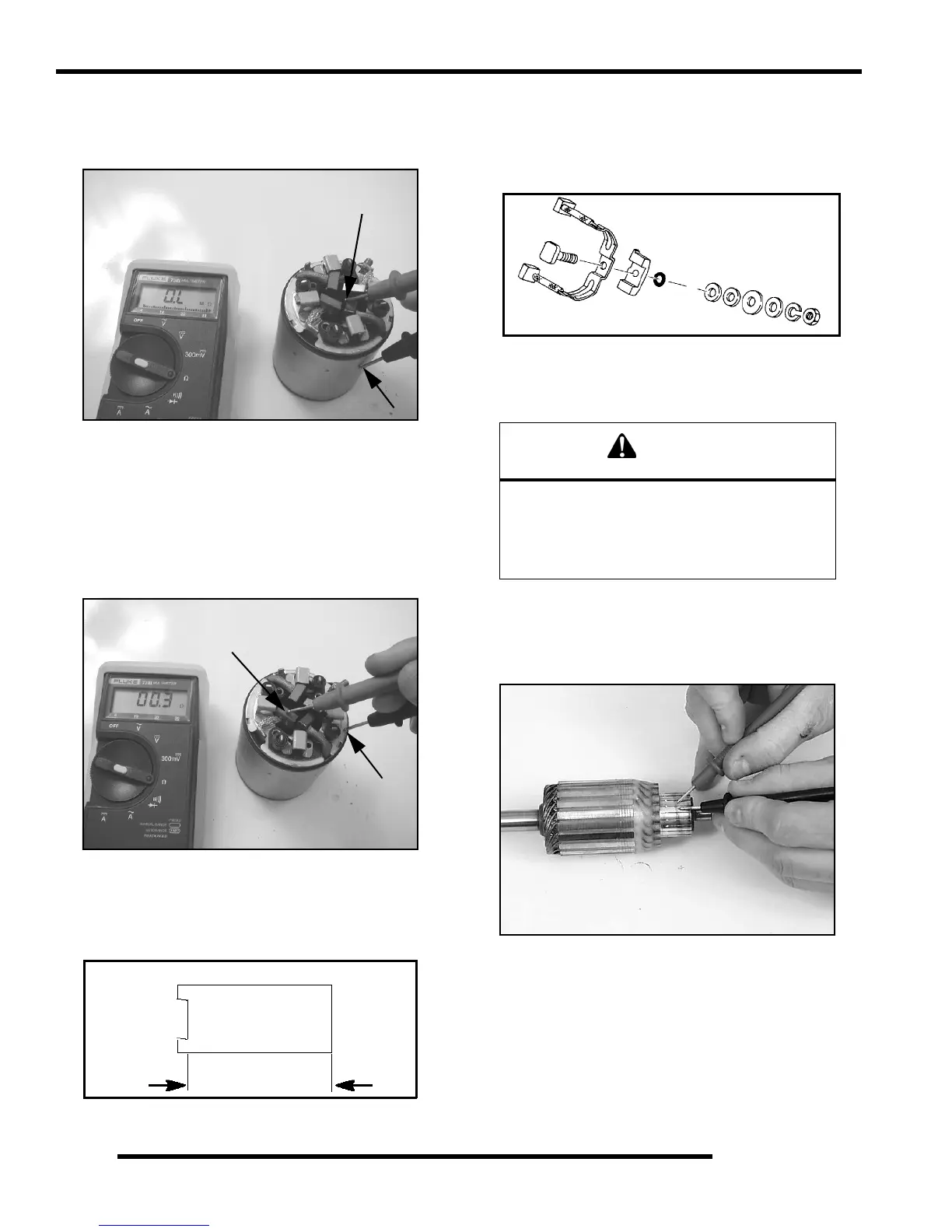

Brush Inspection

1. Measure length of each carbon brush. Replace brush

assembly when worn to 5/16” (8 mm) or less. The brushes

must slide freely in their holders.

Brush Replacement

1. Remove terminal nut with lock washer, flat washer, large

phenolic washer, the small phenolic spacers, and sealing

O-ring. Inspect O-ring and replace if damaged.

2. Slide positive brush springs to the side, pull brushes out of

their guides and remove brush plate.

Armature Testing

1. Remove armature from starter casing. Note order of shims

on drive end for reassembly.

2. Inspect surface of commutator. Replace if excessively

worn or damaged.

3. Using a digital multitester, measure the resistance between

each of the commutator segments. The reading should be

.3 ohms or less.

Limit 5/16” (8 mm)

Brush Length

CAUTION

Some cleaning solvents may damage the

insulation in the starter. Care should be

exercised when selecting an appropriate

solvent. If the commutator needs cleaning use

only electrical contact cleaner.

Loading...

Loading...