FUEL SYSTEM/CARBURETION

3.10

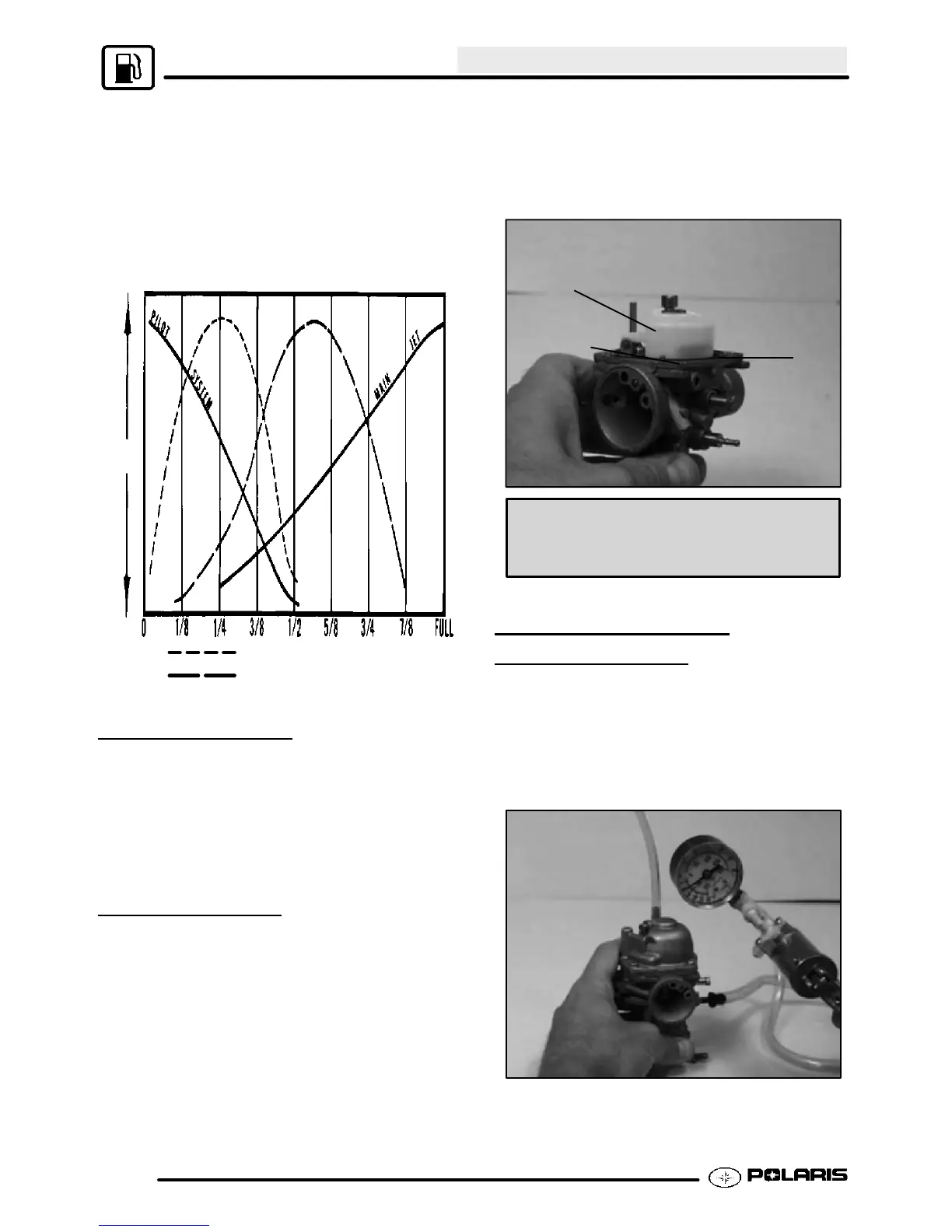

The jet needle and needle jet have an effective

operating range from approximately 1/8 to 7/8 throttle

opening. The amount of fuel delivered during this

range relies upon the jet needle clip position, as well

as the needle jet size and other specifications.

The main jet affects fuel delivery at 1/4 throttle and

consistently increases to full throttle opening.

INCREASING

DECREASING

EFFECT

THROTTLE OPENING - 2 Cycle

Throttle Valve Cut-Away

Jet Needle/Needle Jet

VENT SYSTEMS

The fuel tank vent line supplies atmospheric pressure

to the fuel in the tank. This line must be free of kinks

and restrictions to prevent lean mixture and possible

engine damage. All vent lines must be properly routed

to prevent damage to the line and to prevent

contaminants from entering the fuel system.

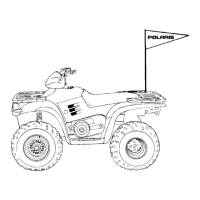

FLOAT HEIGHT

1. Invert the carburetor and remove float bowl.

2. Rest the float tongue lightly on the inlet needle

valve pin without compressing the spring.

3. The float should be parallel ±1mmtothegasket

surface on all youth model ATV carburetors.

When setting the float, be sure inlet needle valve

spring is not compressed. If adjustment is

necessary, bend the tongue slightly.

Parallel

Float

Gasket

Surface

Float Height:

Parallel to Gasket Surface ± 1mm

NEEDLE AND SEAT

LEAKAGE

TEST

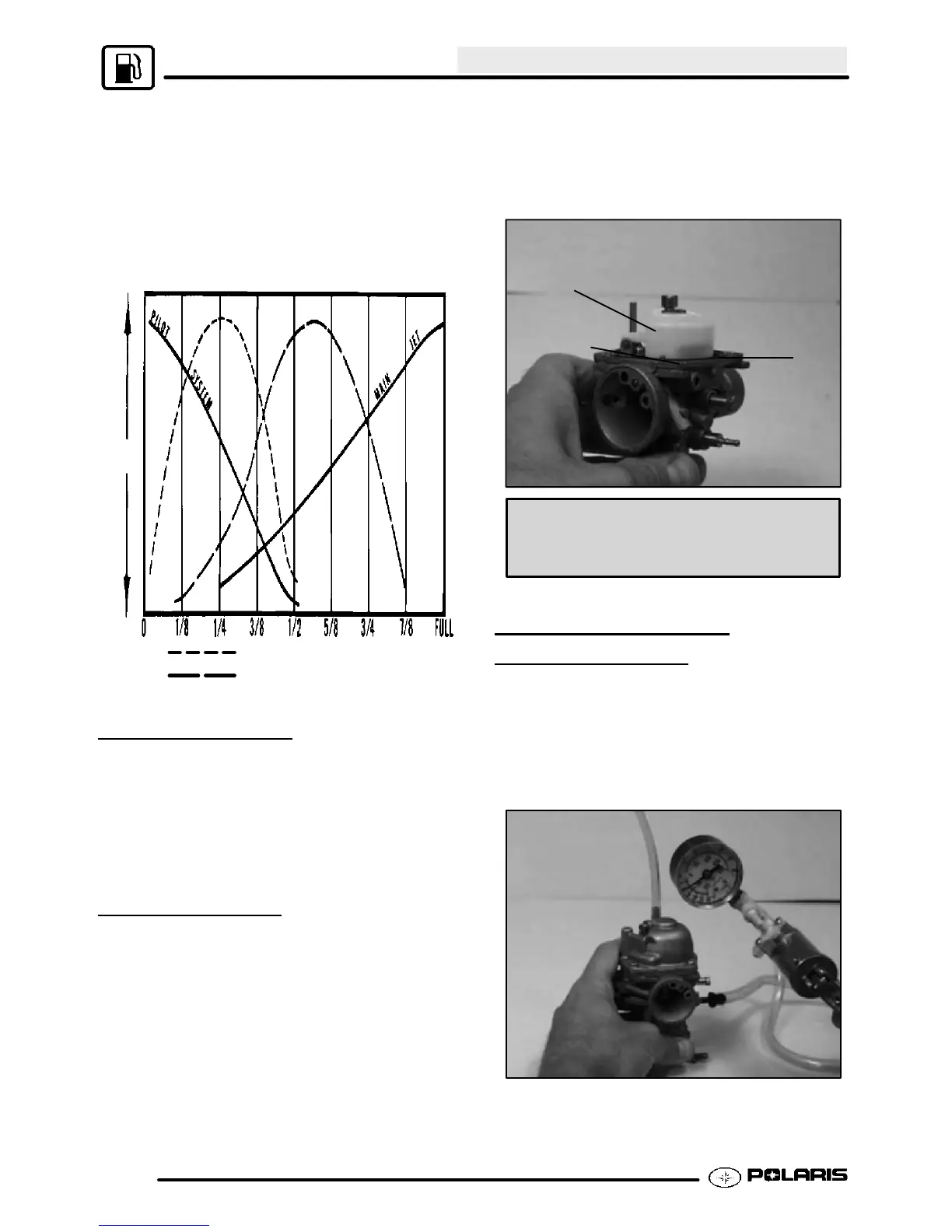

1. Install the float bowl. Invert the carburetor and

install a Mity-Vact (PN 2870975) to the fuel inlet

fitting. Apply 5 PSI pressure to inlet fitting. The

needle and seat should hold pressure indefinitely.

If not, inspect needle and seat and seat O-ring or

gasket.

Enfocus Software - Customer Support

Loading...

Loading...