3.UsingtheT

runnionbracketasatemplate,markanddrillthe5xpilot

holesonthemountingsurface.

4.Securethetrunnionbrackettothemountingsurfaceusingyourself

tappingscrewsandanappropriatescrewdriver.

5.Insertthetrunnionknobsintothesidesofthedisplayandtighten3to

4turns.

6.Slidethedisplayintothetrunnionbracketsothatthetrunnionknob

threadsareslottedintotherecessesinthetrunnionbracket.

7.Securethedisplaybyfullytighteningthetrunnionknobs,ensuringthat

theratchetteetharecorrectlyengaged.

Theknobsshouldbetightenedbyhand,sufficientlytopreventthe

displayfrommovingwhilstyourvesselisunderway.

8.Routeandconnectnecessarycables.

8.4Trunnionmounting—Axiom®2Pro16

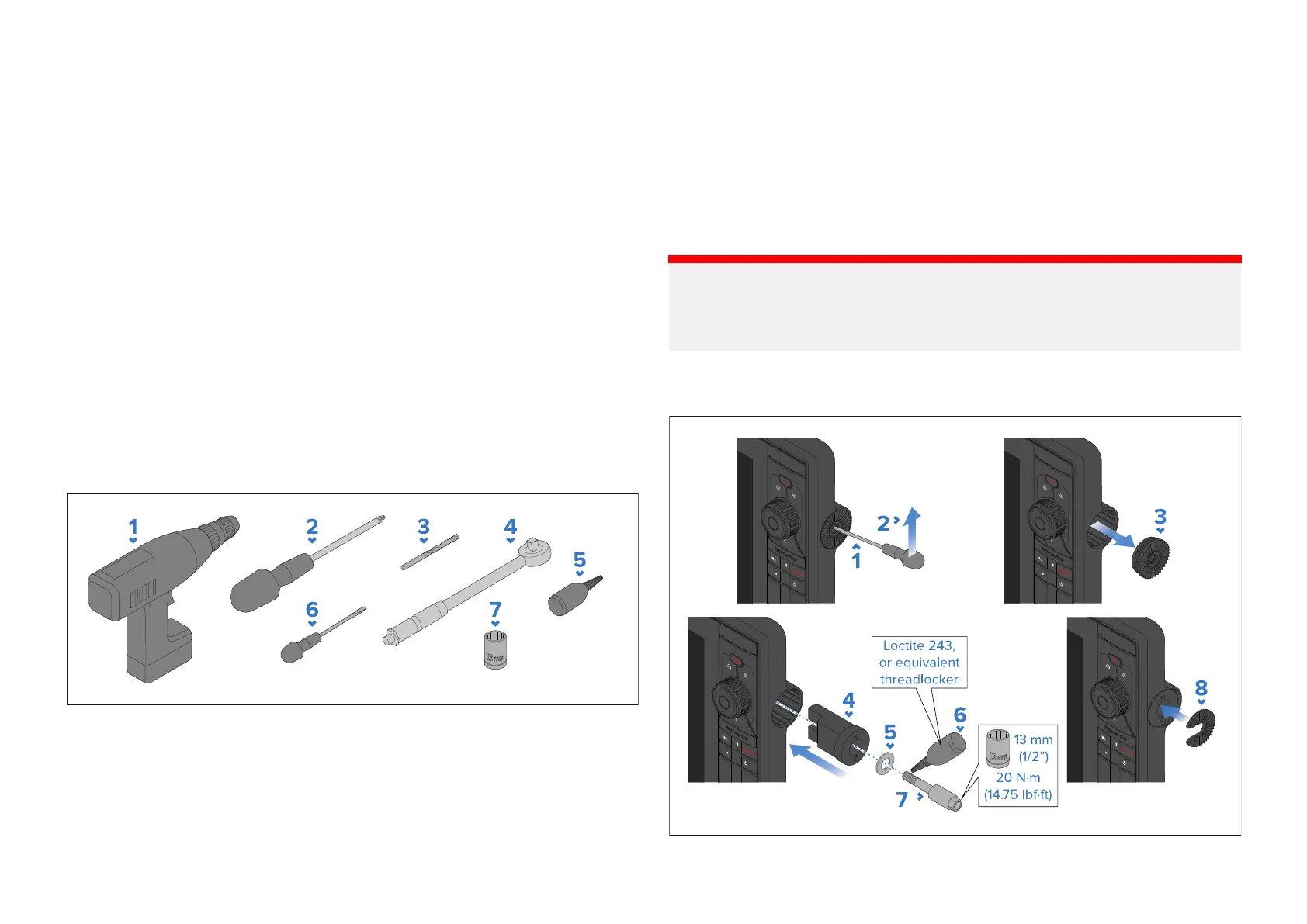

Toolsrequired(trunnionmountinstallations)

Thefollowingtoolsarerecommendedformountingusingatrunnionbracket:

1.P owerdrill.

2.Screwdriver(appropriateforyourfixings).

3.Drillbit(suitableforthematerialofthemountingsurfaceandthe5.75mm

(0.23in)diametermountingholesinthetrunnionbracket).

4.Torquewrench.

5.Loctite®243,orequivalentthreadlocker.

6.Smallflatbladescrewdriver(orplasticprytool).

7.13mm(1/2”)socket.

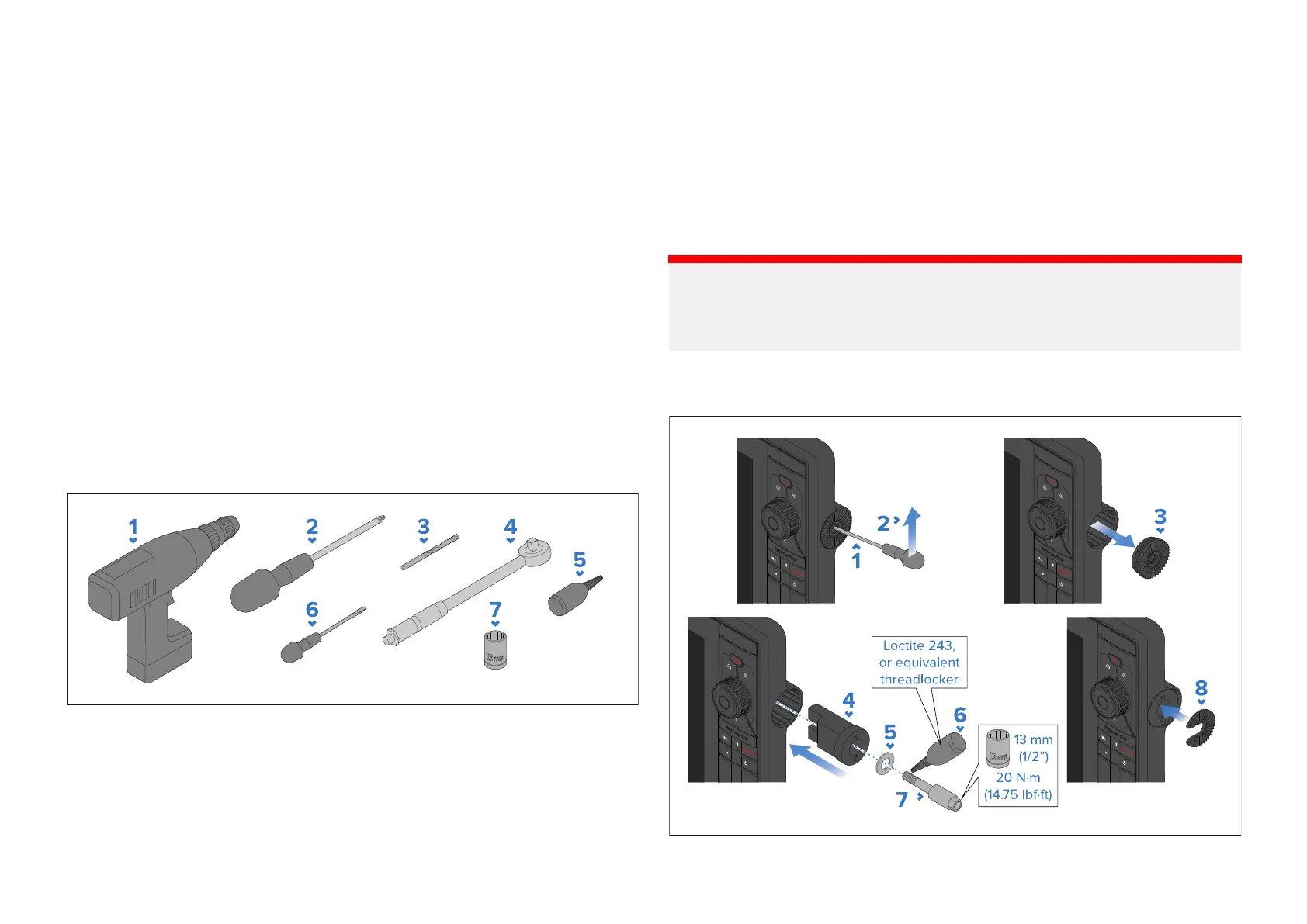

Displaytrunnionmountingpreparation

Axiom®2Pro16displaysareintendedtobeeithersurfaceorflushmounted.

AnoptionalTrunnionbracketkit(partnumber:A80722)isavailableif

trunnionmountingisdesired.Fortrunnionmounting,thedisplayneedstobe

preparedusingthepartssuppliedintheA80722kit.

Important:

Thedisplayissuppliedwithrubbertrunnionbungsfitted,whichmustbe

removedbeforethedisplayistrunnionmounted.DoNOTattemptto

trunnionmountthedisplayusingthetrunnionbungs.

Topreparethedisplayfortrunnionmounting,followthestepsbelow,for

bothsidesofthedisplay:

42

Loading...

Loading...