Transmission of Scanner Commands

MP150 Protocol Rev. B4 Aug 2019 11

3.4 Error Handling

If the scanner, upon a command or a parameter request, answers ETB instead of ACK/NAK, an error in

the scanner has occurred.

After the acknowledgment signal ETB from the scanner, indicating an error, the scanner only accepts

the error status parameter request: GES which it will respond as described in section 3.3: ES<error

code>.

The meaning of the <error code> is given in table Table 1.

If other commands or parameter requests are transmitted, the scanner will continue to respond with

ETB; with the exceptions:

• GES to get the error,

• CC to switch to the calibration mode. In the Calibration mode this ETB-behaviour is switched

off.

The command itself will still be executed, even if it answers with ETB only.

In case of recoverable errors, the reset of the error message is possible, and continued operation may be

achieved by issuing the command ES.

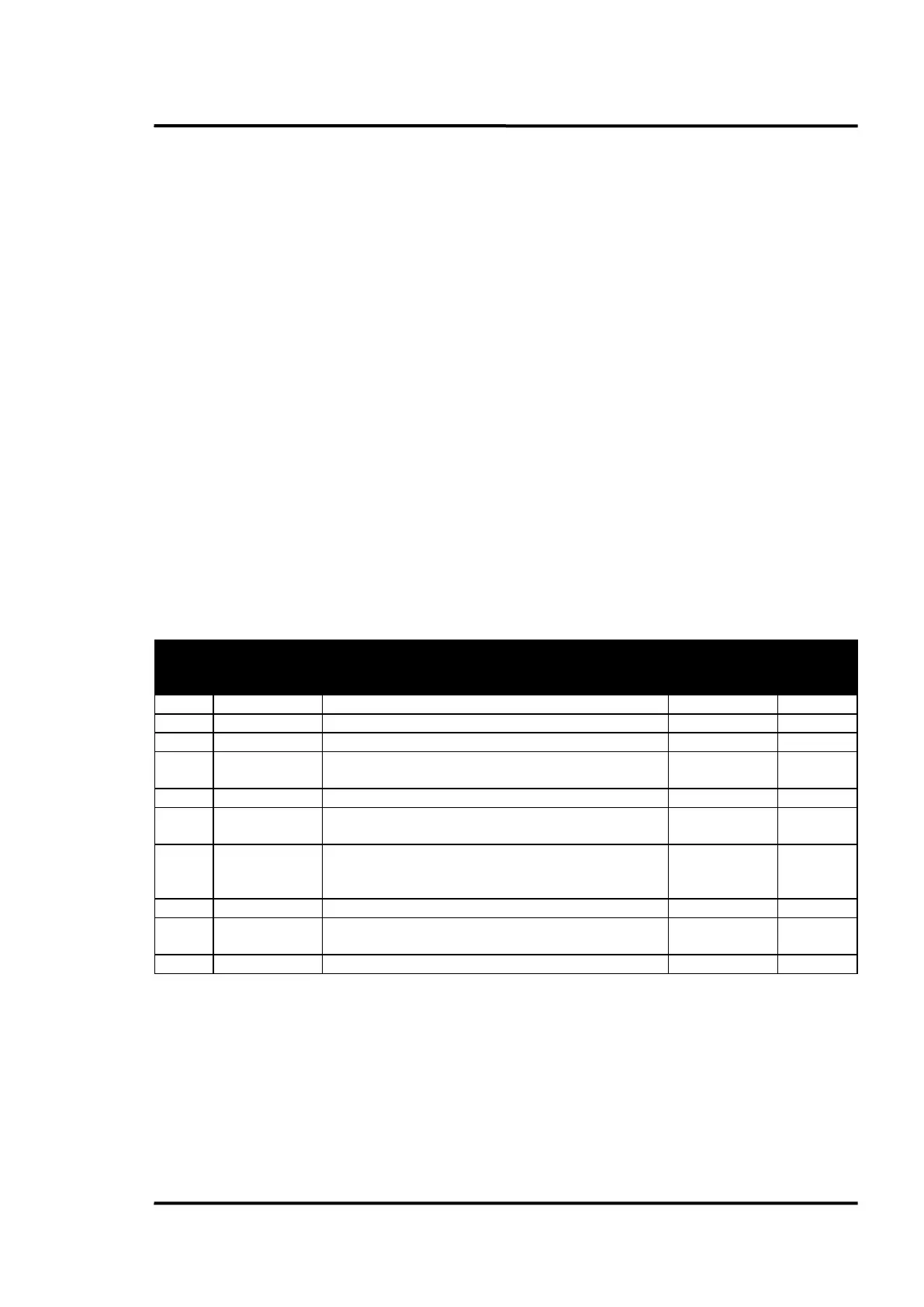

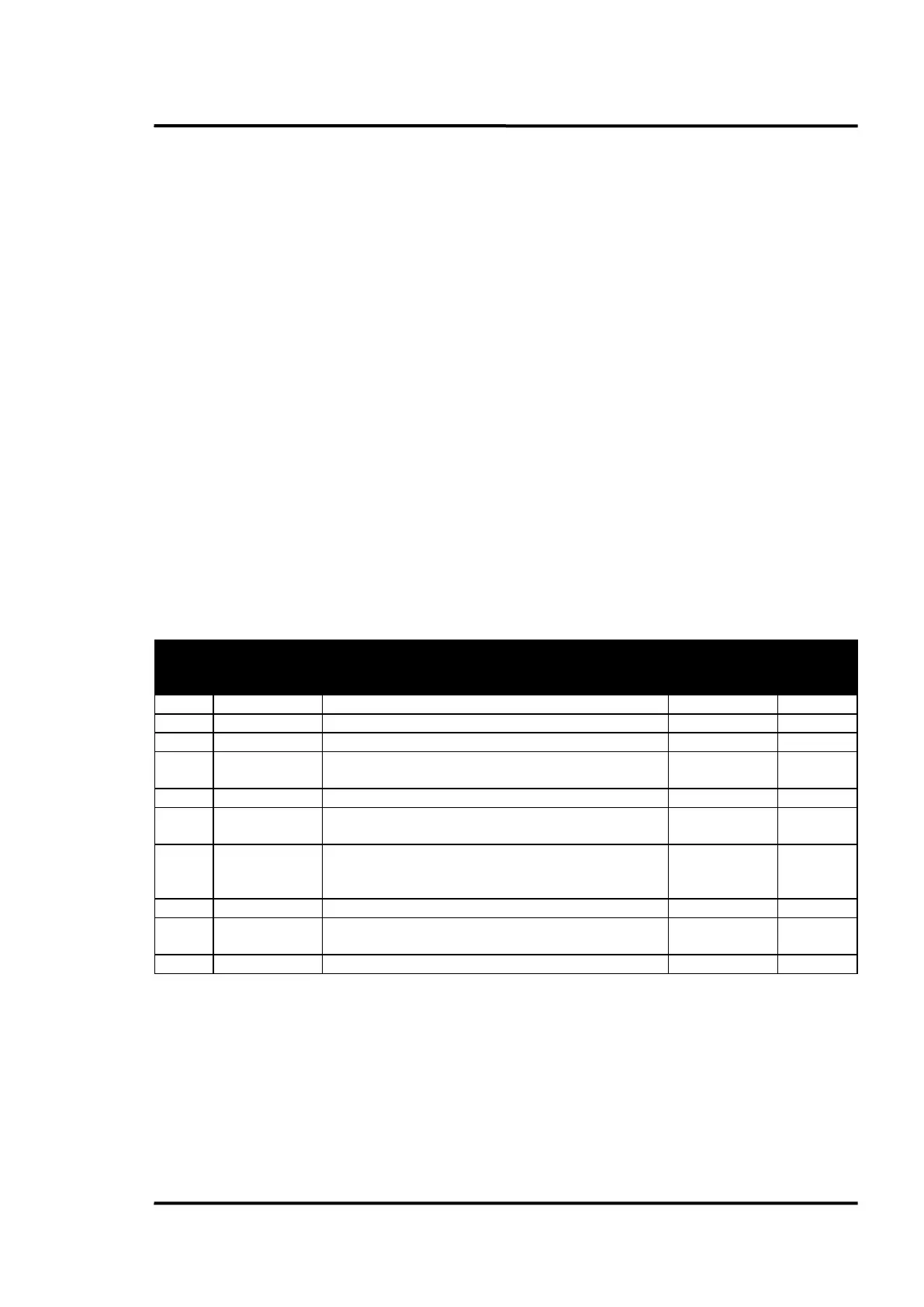

The following errors are defined and can be asked for using the GES command. Bit positions of multiple

errors are or-ed up in the answer as described below the table.

Table 1

Example 1: active error bits 0, 1, 30 result in the answer 40000003 (1hex + 2hex + 40000000hex)

Example 2: active error bits 0, 1, 3 result in the answer:

Result / answer: 1hex + 2hex + 8hex = Bhex

Loading...

Loading...