70

Gas Supply

IMPORTANT: Any additions, changes or conversions re-

quired for the furnace to satisfactorily meet the application

should be made by a qualified installer, service agency or

the gas supplier, using factory-specified or approved parts.

IMPORTANT: Connect this furnace only to gas supplied by

a commercial utility or commercial fuel provider.

IMPORTANT: U.L. or CSA recognized fuel gas and carbon

monoxide (CO) detector(s) are recommended in all appli-

cations, and their installation should be in accordance with

the manufacturer’s recommendations and/or local laws,

rules, regulations or customs.

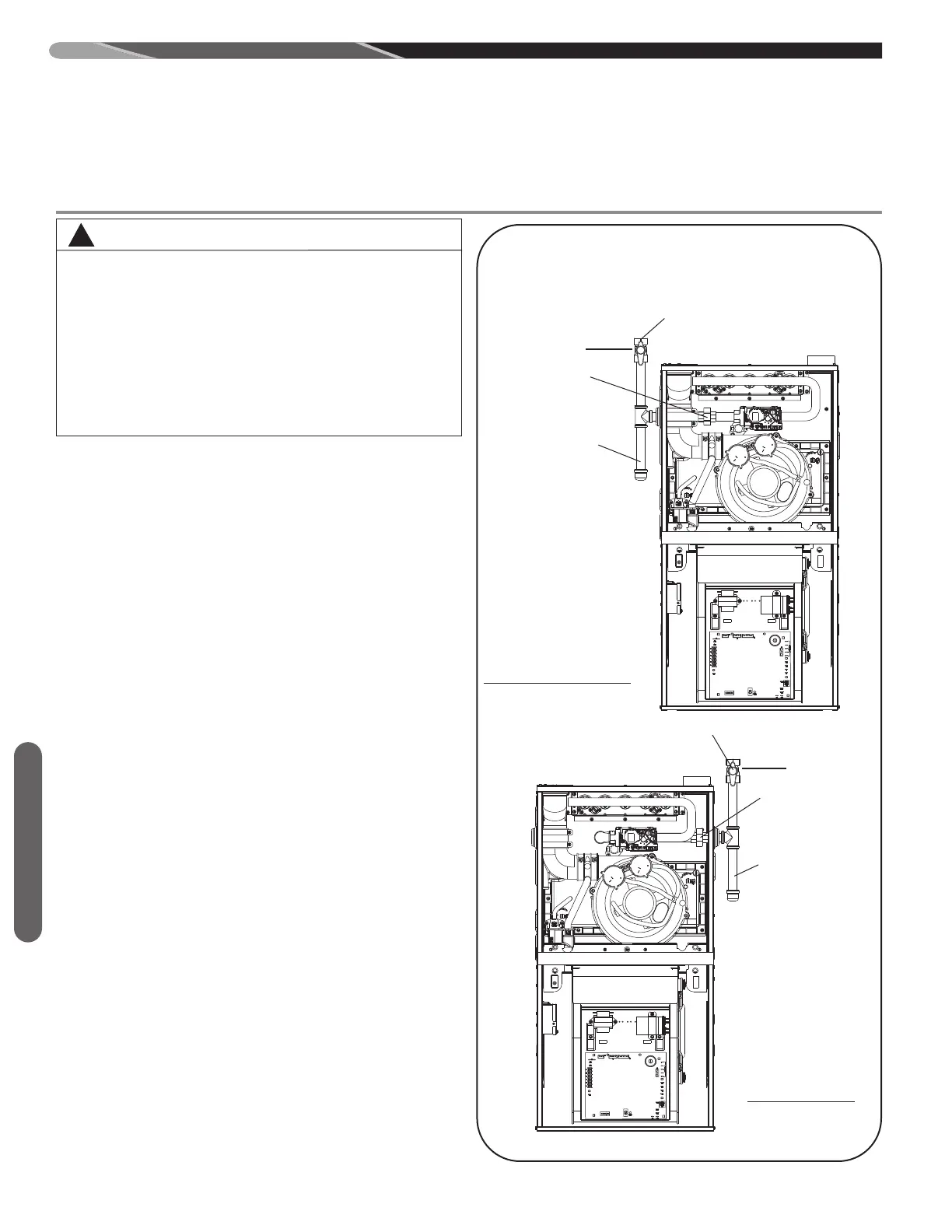

Install the gas piping according to all local codes and regu-

lations of the utility company.

If possible, run a separate gas supply line directly from the

meter to the furnace. Consult the local gas company for

the location of the manual main shut-off valve. The gas

line and manual gas stop must be adequate in size to

prevent undue pressure drop and never smaller than

the pipe size to the gas valve on the furnace. Refer to

Table 12 for natural gas (Table 13 for LP gas) for the rec-

ommended gas pipe size. See Figure 36 for typical gas

pipe connections.

Install a ground joint union within 3 feet of the cabinet

to easily remove the gas valve assembly. Local codes

may dictate the location of the ground joint union. In-

stall a manual shut-off valve in the gas line outside of

the furnace casing and upstream of the ground joint

union. The manual shut-off valve should be readily acces-

sible to turn the gas supply on or off. Install a drip leg in

the gas supply line as close to the furnace as possible. Al-

ways use a pipe compound resistant to the action of lique-

fied petroleum gases on all threaded connections.

IMPORTANT: When making gas pipe connections, use a

back-up wrench to prevent any twisting of the main gas

valve and manifold. Do not overtighten gas valve on pipe.

Any strains on the gas valve can change the position of

the gas orifices in the burners. This can cause erratic fur-

nace operation.

GAS

S

UP

P

L

Y

GA

S

P

I

P

I

N

G

ST-A1205-02-X0 ST-A1205-02-X0

MANUAL SHUT-OF VALVEMANUAL SHUT-OF VALVE

UNION

D

RIP LEG

UNION

DRIP LEG

ST-A1205-02-X0 ST-A1205-02-X0

MANUAL SHUT-OF VALVEMANUAL SHUT-OF VALVE

UNION

DRIP LEG

UNION

DRIP LEG

ST-A1205-02-X0

FIGURE 36

G

AS PIPING INSTALLATION

!

W

A

RNI

NG

THIS FURNACE IS EQUIPPED AT THE FACTORY

FOR USE ON NATURAL GAS ONLY. CONVERSION

TO LP GAS REQUIRES A SPECIAL KIT IS AVAIL-

ABLE AT THE DISTRIBUTOR. FAILURE TO USE THE

PROPER CONVERSION KIT CAN CAUSE FIRE,

CARBON MONOXIDE POISONING, EXPLOSION,

PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH. SEE THE CONVERSION KIT INDEX SUP-

PLIED WITH THE FURNACE. THIS INDEX IDENTI-

FIES THE PROPER LP GAS CONVERSION KIT

REQUIRED FOR EACH PARTICULAR FURNACE.

CONVENTIONAL

ALTERNATE

UPFLOW

(CONTINUED ON NEXT PAGE)

4-5 FEET ABOVE

FLOOR REQUIRED

BY SOME UTILITIES

4-5 FEET ABOVE

FLOOR REQUIRED

BY SOME UTILITIES