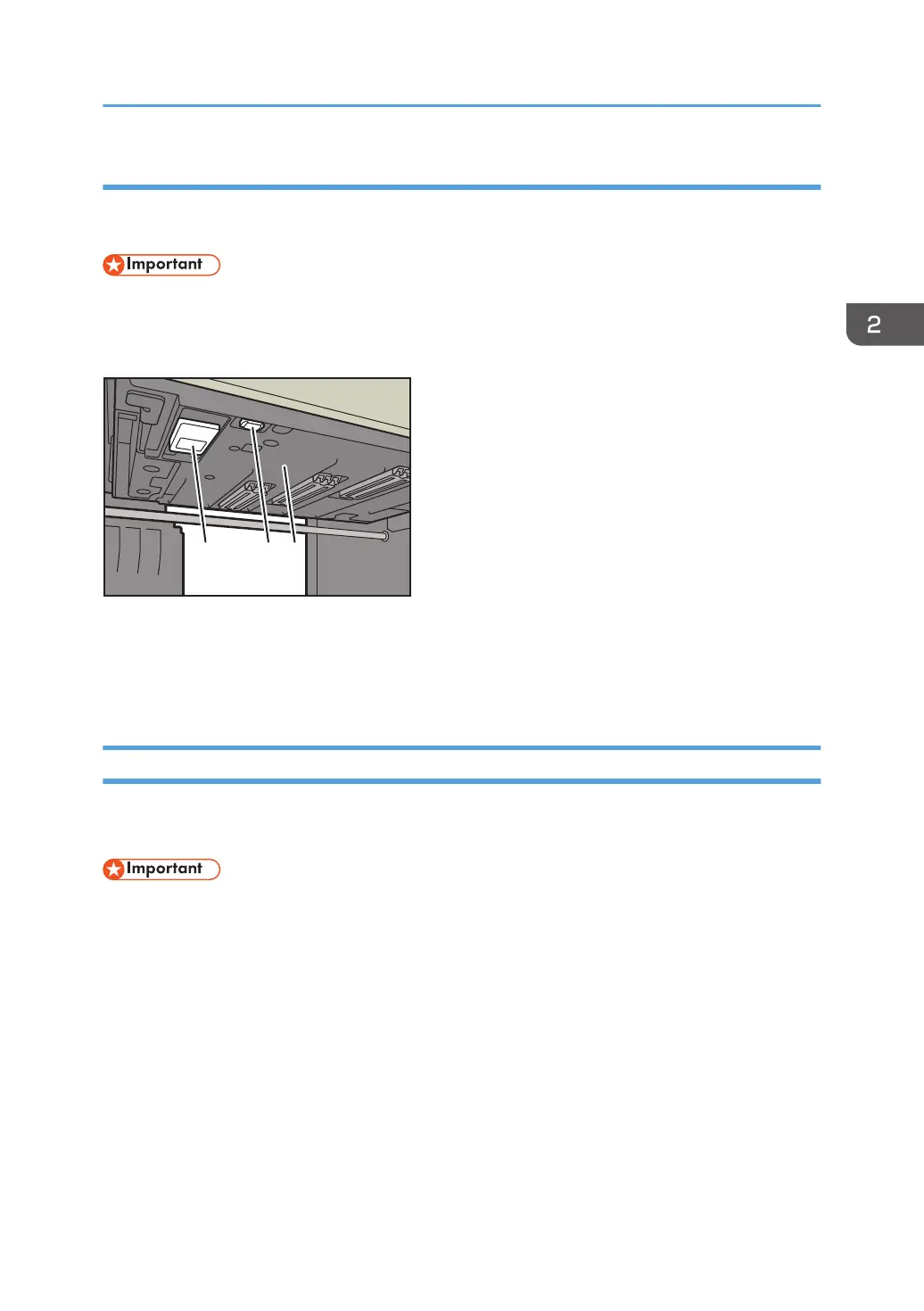

Cleaning the media sensor on the underside of the carriage

When cleaning the media sensor on the underside of the carriage, see page 21 "Cleaning the Area

around the Print Heads".

• When cleaning the media sensor on the underside of the carriage, do not touch the sensors with

your hand. Touching the sensors may cause malfunctions.

• Do not touch the colorimetric sensor as cleaning may cause the sensor to become misaligned.

1. Colorimetric sensor

2. Media sensor

3. Underside of the carriage

Cleaning the Nozzle Faces of the Print Heads

When nozzle clogging defects cannot be resolved even when performing head cleaning or air purging,

clean the nozzle faces of the print heads.

• Do not place any object on the platen as the carriage moves there.

• When the carriage moves, it may make contact with media. Check that the media is not deformed

or that there is no floating media.

• When 10 minutes or more have passed after the carriage moves, the machine will make a buzzer

sound. As nozzle dryness may cause a nozzle defect, perform nozzle maintenance promptly.

• For cleaning liquid, use only the manufacturer-recommended cleaning liquid bottle. For details, see

page 60 "List of Consumables".

Maintenance When Needed

31

Loading...

Loading...