1.Detailed Descriptions

4

consisting of a claw unit press motor holds down and flattens the booklet in preparation for trimming.

Cutter Unit

There is a cutter unit between the feed unit and the trim positioning unit. The unit has a guillotine cutter:

the upper blade has a sharp edge and moves according to the shearing angle, while the lower blade is

blunt and is fixed at an obtuse edge of about 90 degrees. The upper blade of the cutter unit drops down

to cut the booklet at the specified trim position. In order to prevent the stack of sheets from shifting

during trimming, a press mechanism firmly holds down the booklet near its trim edge, before the upper

blade is lowered.

Scrap Hopper

Paper scraps drop down from the cutter unit into the scrap hopper underneath the cutting section.

Sensors detect if the scrap hopper is set, and when it is full.

Tray Unit

After the booklet is trimmed, pressure on the booklet is released, and it is transported to the exit of the

trim positioning unit by a transport mechanism at the lower end of the unit. The booklet is then output to

the tray by paper exit rollers (not shown in diagram). A flat belt is driven to transfer each booklet slowly

onto the output tray, so as to ensure that they are stacked properly. By changing the amount that the

belt moves according to the size and thickness of the booklet, the overlap amount between booklets

can be adjusted, so that stacking and stack capacity can be assured.

Tray Full is detected using a combination of Exit Tray Sensor 2, which detects the rotation angle of the

paper exit lever at the paper exit, and Exit Tray Sensor 1 at the front edge of the paper exit tray,

Specifically, when the Paper Remaining Sensor and Exit Tray Sensor 1 turn on, and Exit Tray Sensor 2

reaches a certain angle, a tray full signal is sent.

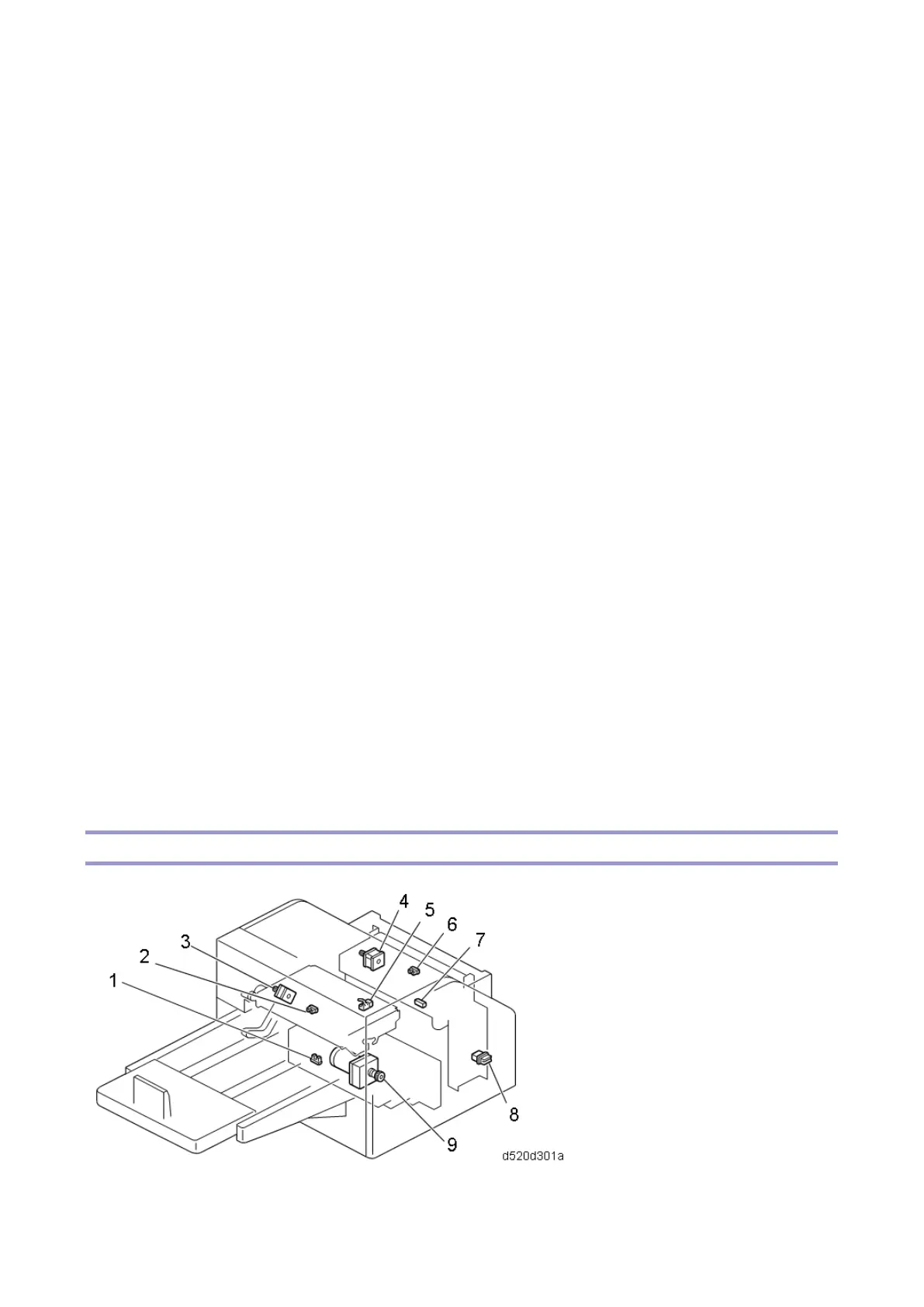

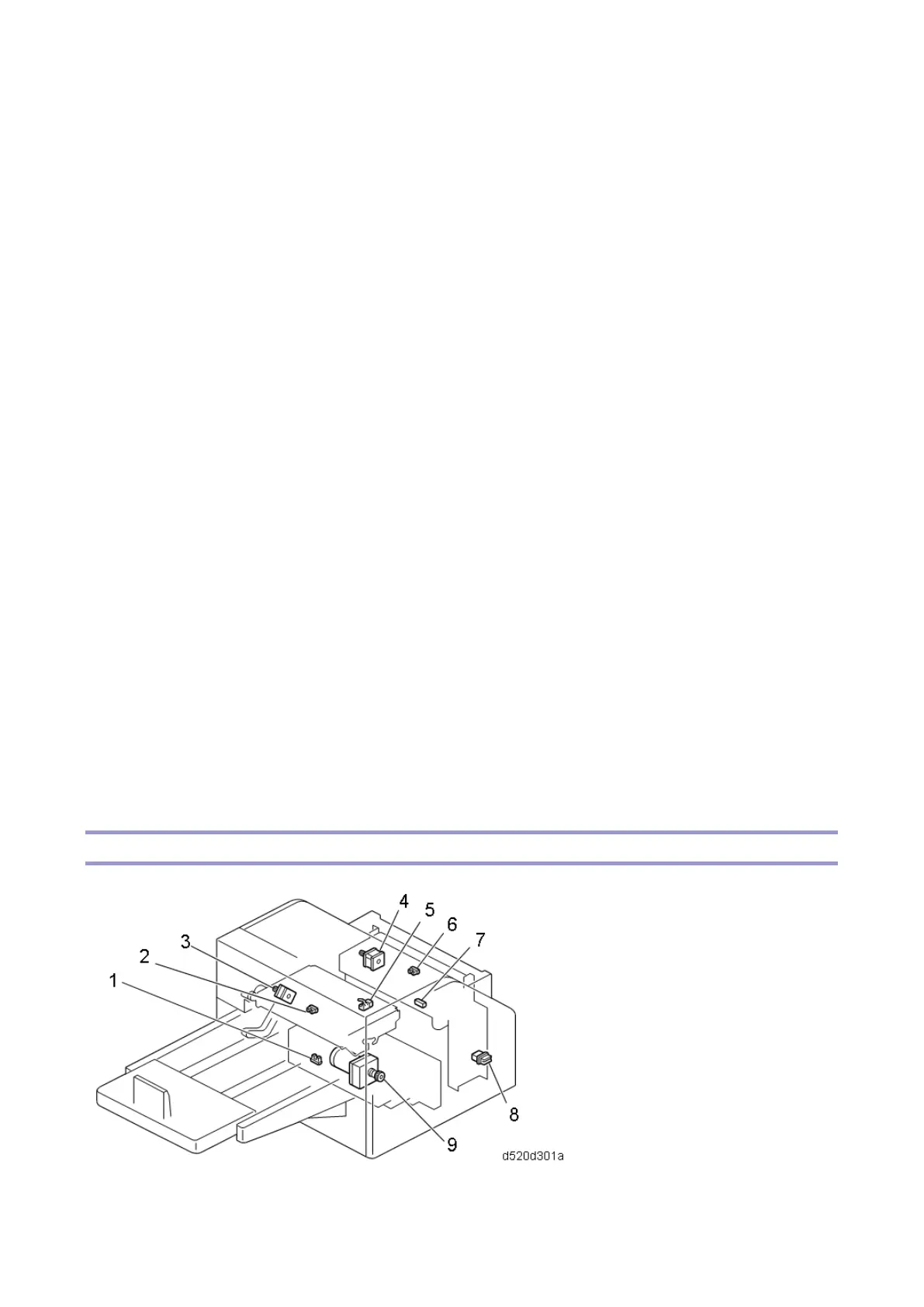

Electrical Component Layout

Loading...

Loading...