Loading...

Loading...

Do you have a question about the Ryobi BDS4600 and is the answer not in the manual?

Pre-operation checks, learning controls, and understanding safety rules.

Safe placement, environment, and handling to prevent injury.

Essential pre-use inspection and checks for damaged parts.

Broad safety advice on environment, tools, clothing, and operations.

Lists model number, power, belt/disc sizes, and table dimensions.

Details on grounding, outlet type, and electrical safety warnings.

Lists the necessary tools for assembly and setup.

Verifying all parts are present before assembly.

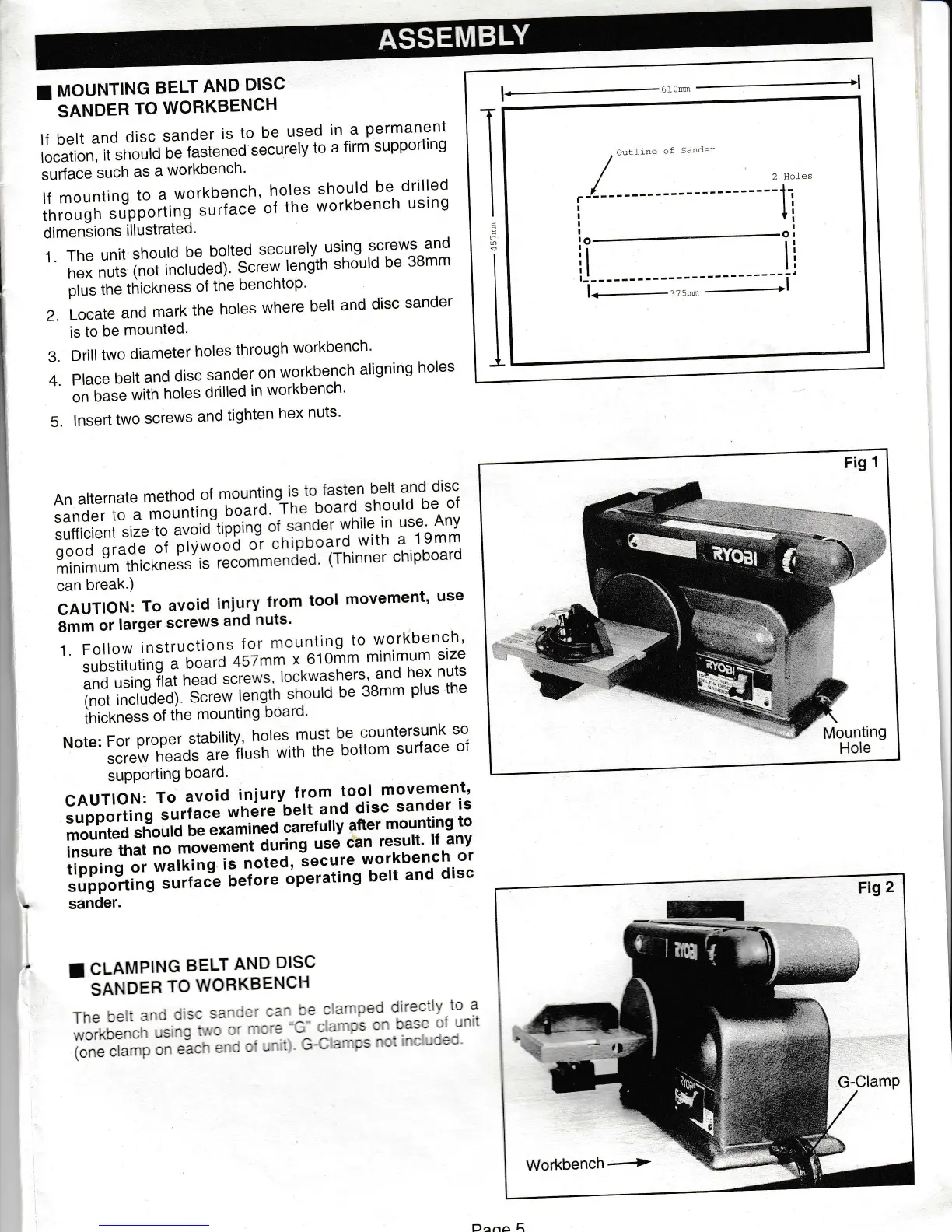

Instructions for securely fastening the sander to a workbench.

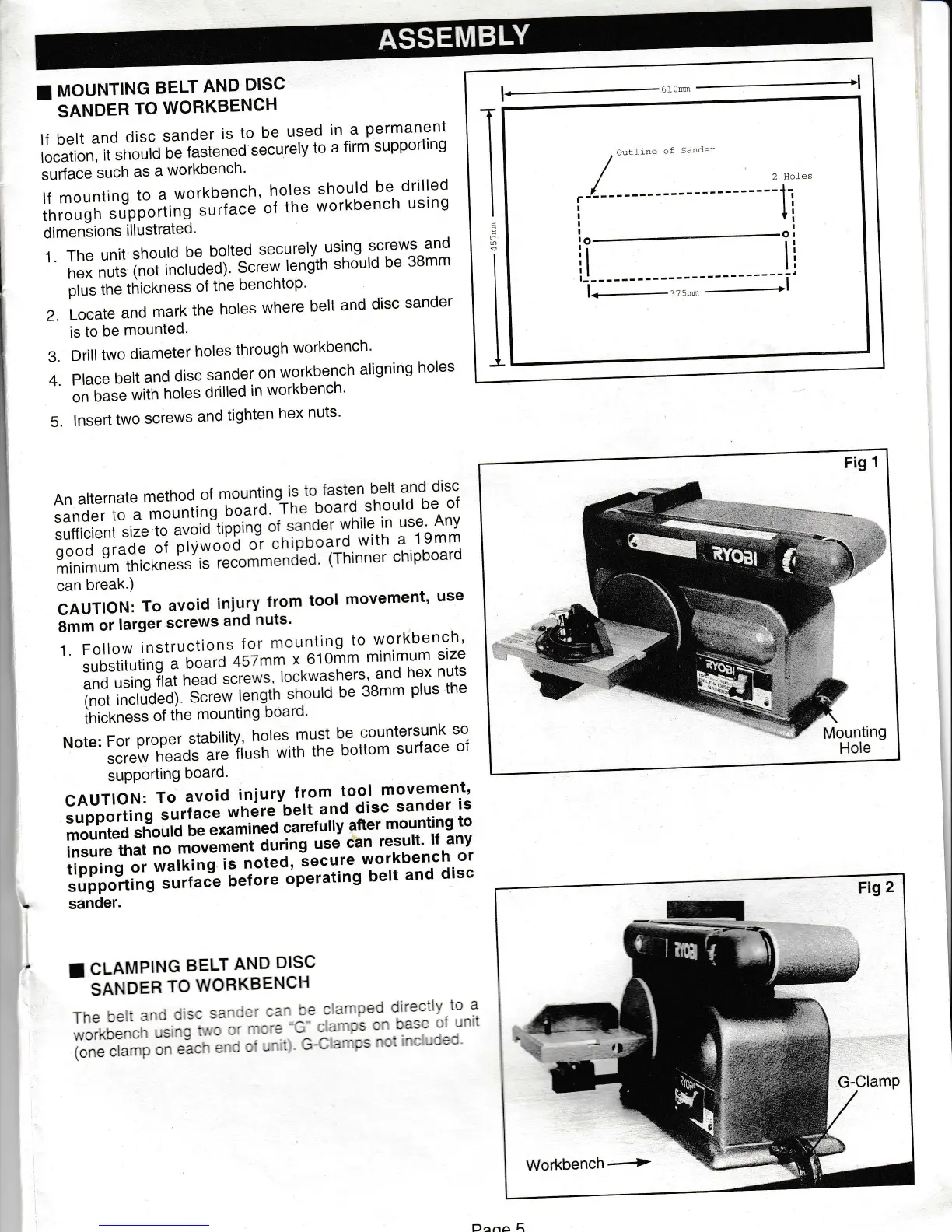

Alternative method for securing the sander using clamps.

Steps to install the sanding disc and its protective guard.

How to fit the work support stop for workpiece stability.

Details on fitting the table assembly to the sander.

How to set up the sander for vertical sanding operations.

Ensuring the worktable is at a 90-degree angle to the disc.

Adjusting belt tension and ensuring proper belt alignment.

Identifies and describes the main parts of the belt and disc sander.

Explains how to use the switch and its safety locking feature.

Instructions for tilting the worktable for bevel sanding.

How to change the belt assembly orientation from horizontal to vertical.

Sanding ends of long workpieces with the belt in a vertical position.

General techniques for surface sanding using the belt.

How to sand inside curves on the idler drum.

How to sand outside curves on the sanding disc.

Techniques for sanding small end surfaces on the disc.

Details on lubricating ball bearings and sleeve bearings.

Steps to remove the pulley cover for maintenance access.

Adjusting the tension of the drive belt for proper operation.

Reattaching the pulley cover after maintenance.

Addresses motor, speed, belt, and noise issues with probable causes and remedies.

Details coverage, exclusions, and duration of the product warranty.

Lists addresses and phone numbers for obtaining warranty service.

A visual breakdown showing all parts of the sander.

Lists individual parts with part numbers, names, availability, and prices.