PLC Subroutines Manual

6FC5397-0FP40-0BA0, 08/2013

73

Table 5-4 Definition of user-defined keys on the MCP

User-defined key 1 Working lamp

User-defined key 2 Manual cooling

User-defined key 3 Safe door

User-defined key 4 Manual clockwise rotation of the tool magazine

User-defined key 5 Manual reset of the tool magazine

User-defined key 6 Manual counter-clockwise rotation of the tool magazine

User-defined key 7 Removing chip forward

User-defined key 8 Removing chip backward

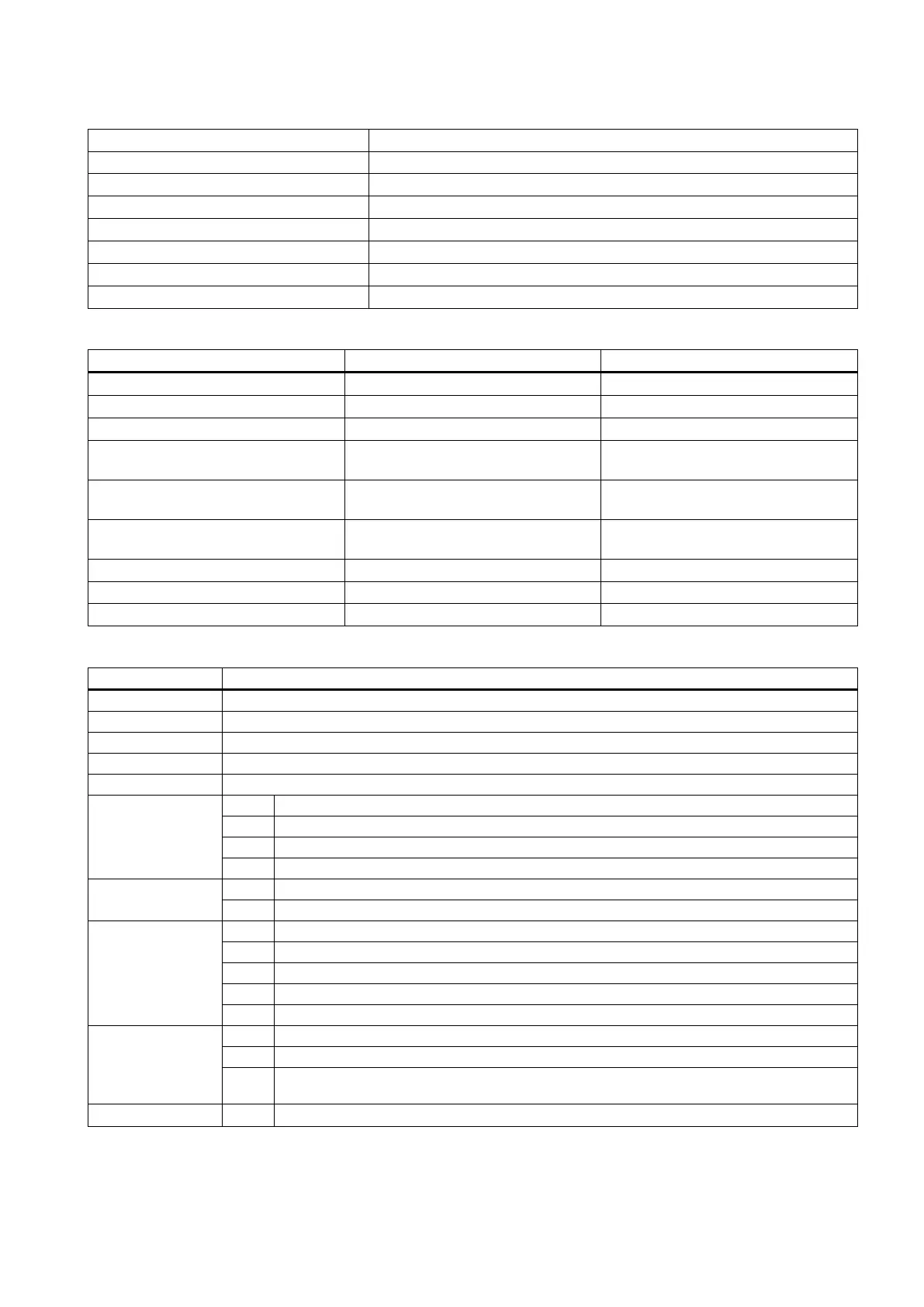

Structure of the sample application (OB1)

Each scan (SM0.0) AUX_MCP (SBR20) Auxiliary function

First scan (SM0.1) PLC_INI (SBR32) PLC initialization

Each scan (SM0.0) EMG_STOP (SBR33) Emergency Stop control

Each scan (SM0.0) MCP_NCK (SBR37) Transferring MCP and HMI signals to

the NCK interface

Each scan (SM0.0) HANDWHL (SBR39) Selecting a hand wheel through the

interface signal DB1900.DBB1xxx

Each scan (SM0.0) AXIS_CTL (SBR40) Coordinate enabling control, hardware

limit, etc.

Each scan (SM0.0) SPINDLE (SBR42) Spindle control

Each scan (SM0.0) COOLING (SBR44) Cooling control

Each scan (SM0.0) LUBRICAT (SBR45) Lubrication control

Setting relevant PLC machine data

The maximum number of tool positions

Lubrication interval (in 1min)

Lubrication duration (in 0.01s)

14512[16]

When the function of safe door is active, it can be triggered by M01/M02

Handwheel assignment with the MCP / HMI

14512[17]

Selection between handwheel and hand-held unit (0: handwheel; 1: hand-held unit)

14512[18]

One time automatic lubrication after the power-on

Stop signal for an external spindle

Fixing the direction of a spindle

Hardware limit is independent of the PLC application

One hardware limit triggered per axis (enabled when bit 6=0)

14512[19]

Function of spindle braking

Password clearing by power-on (0: delete the password; 1: do not delete the password)

Bit 7 MM+ (Manual Machine Plus) function (enabled when the MM+ has been licensed and

corresponding PLC subroutine has been called)

14512[20] Bit 1 Spindle disable mode

Loading...

Loading...