HGM6100LT Series Genset Controller User Manual Page 7 of 50

All parameters use digital modulation, instead of analog modulation using conventional

potentiometer, having improved reliability and stability;

With maintenance function. Types (date or running time) can be selected and actions (warning or

alarm shutdown) can be set when maintenance time out;

Event log (max.99 pieces), real-time clock, scheduled start & stop (can be set as start unit once a

day/week/month whether with load or not);

Add rubber gasket between shell and controller screen, the waterproof can reach IP65;

Controller is fixed by metal fixing clips;

Modular design, flame-retardant ABS shell, embedded mounting, compact structure and easy

installation.

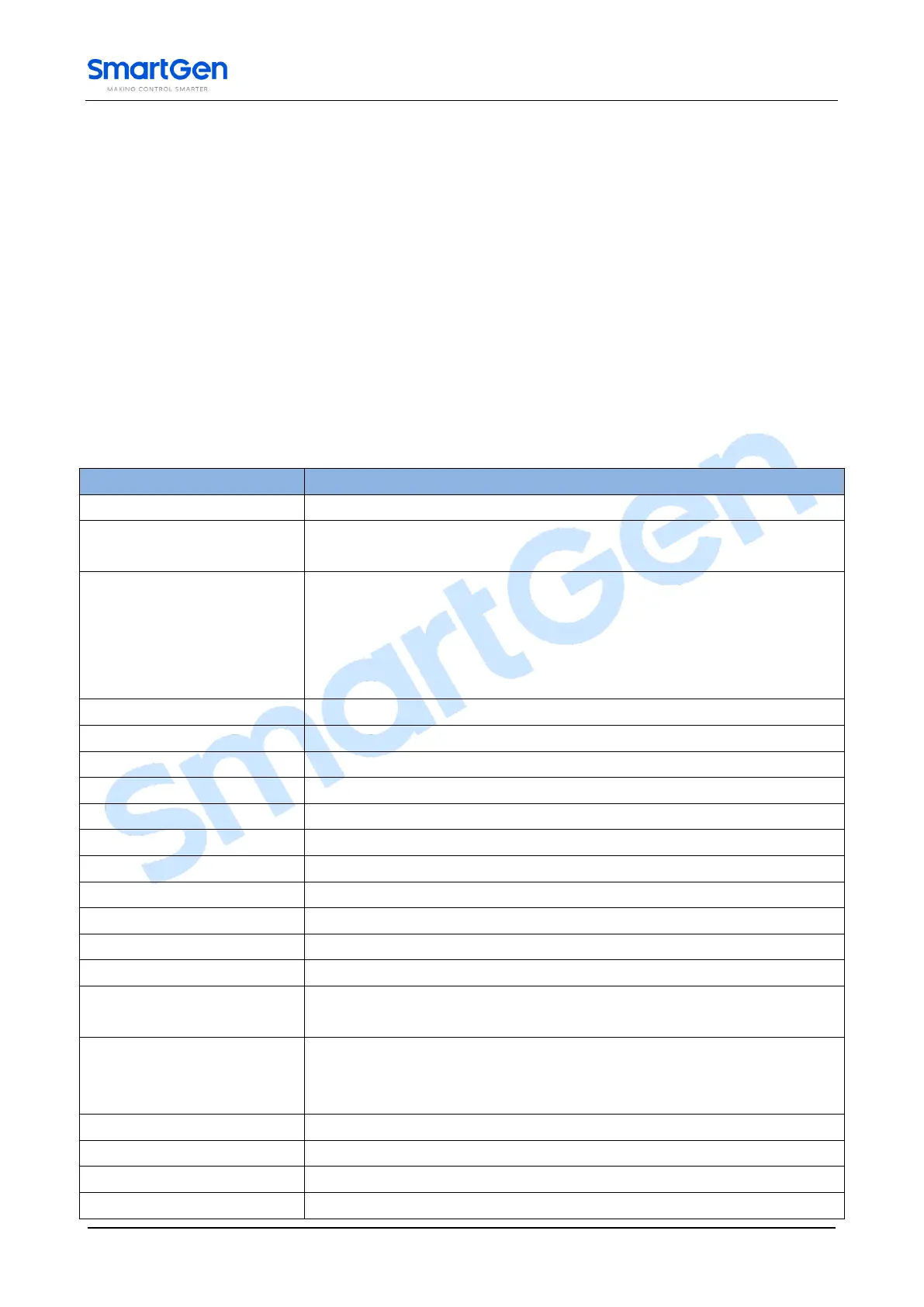

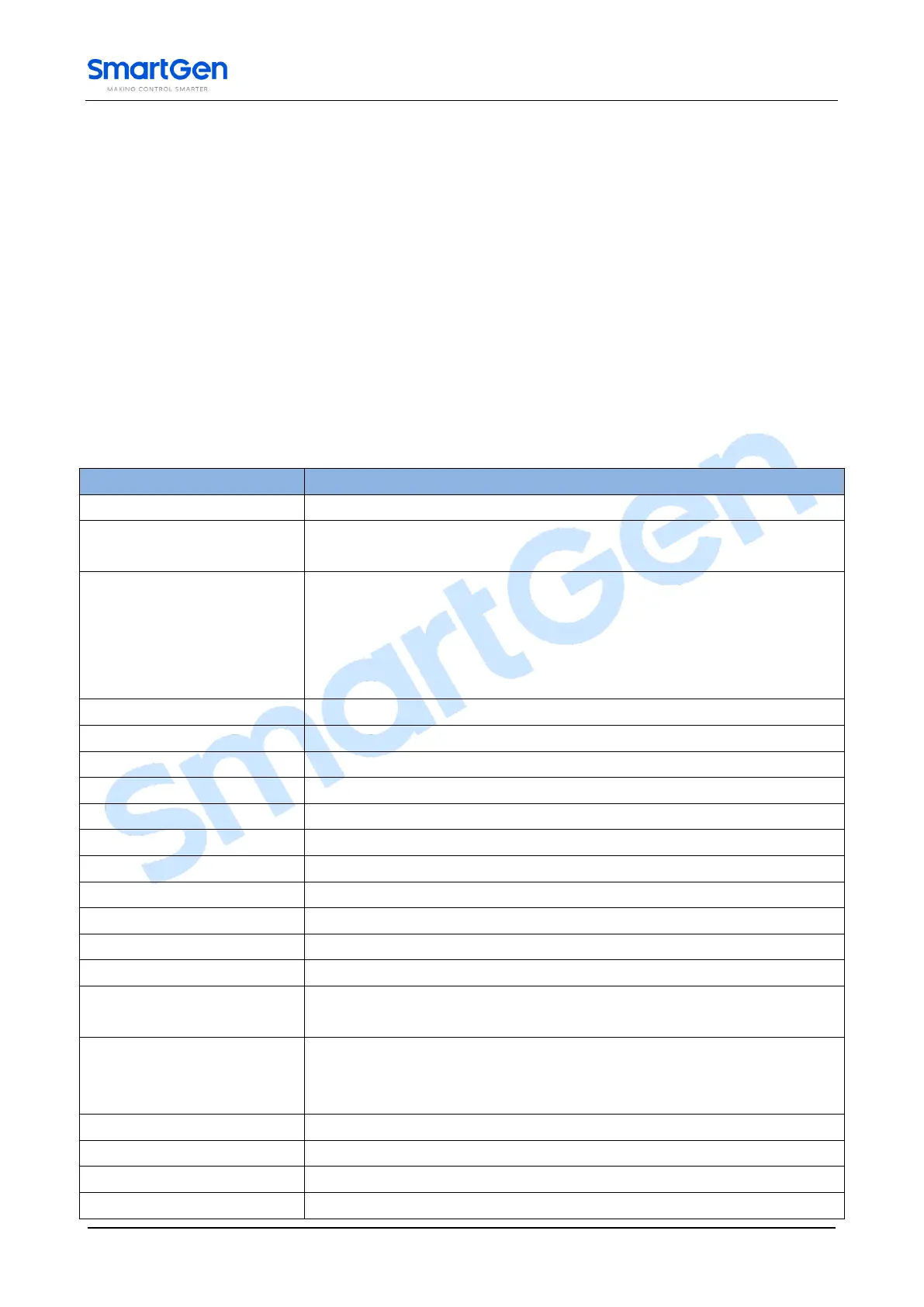

3 SPECIFICATION

Table 2 – Technical Parameters

DC8.0V to DC35.0V, continuous power supply

LCD without heating: <6W (standby: ≤2W)

LCD with heating: <10W (standby: ≤6W)

AC System

3P4W

3P3W

1P2W

2P3W

15V AC - 360 V AC (ph-N)

30V AC - 620 V AC (ph-ph)

15V AC - 360 V AC (ph-N)

15V AC - 360 V AC (ph-N)

16A DC28V at supply voltage

16A DC28V at supply voltage

7A DC28V at supply voltage

7A AC250V volt-free output

16A AC250V volt-free output

16A AC250V volt-free output

Isolated RS485 port, Modbus-RTU protocol

RJ45 10/100Mbps self-adapt network interface

Cloud monitoring protocol and TCP/IP Modbus protocol

Under the condition of -40ºC, the controller can display normally within

20s after power-on; after 2 minutes after power-on, the dynamic display

response speed is normal.

Loading...

Loading...