12

3 Preparation

3.1 Instrument Preparation and Inspection

Calibration of the instrument is performed by using a standard calibrated test block.

The error and repeatability of displayed value should be within +/-6HL points (D

device) The instrument and impact device must be calibrated using a standard

hardness block prior to first usage or having reset the instrument system.

CALIBRATION PROCEDURE:

Press key, while simultaneously pressing down the key to power on the

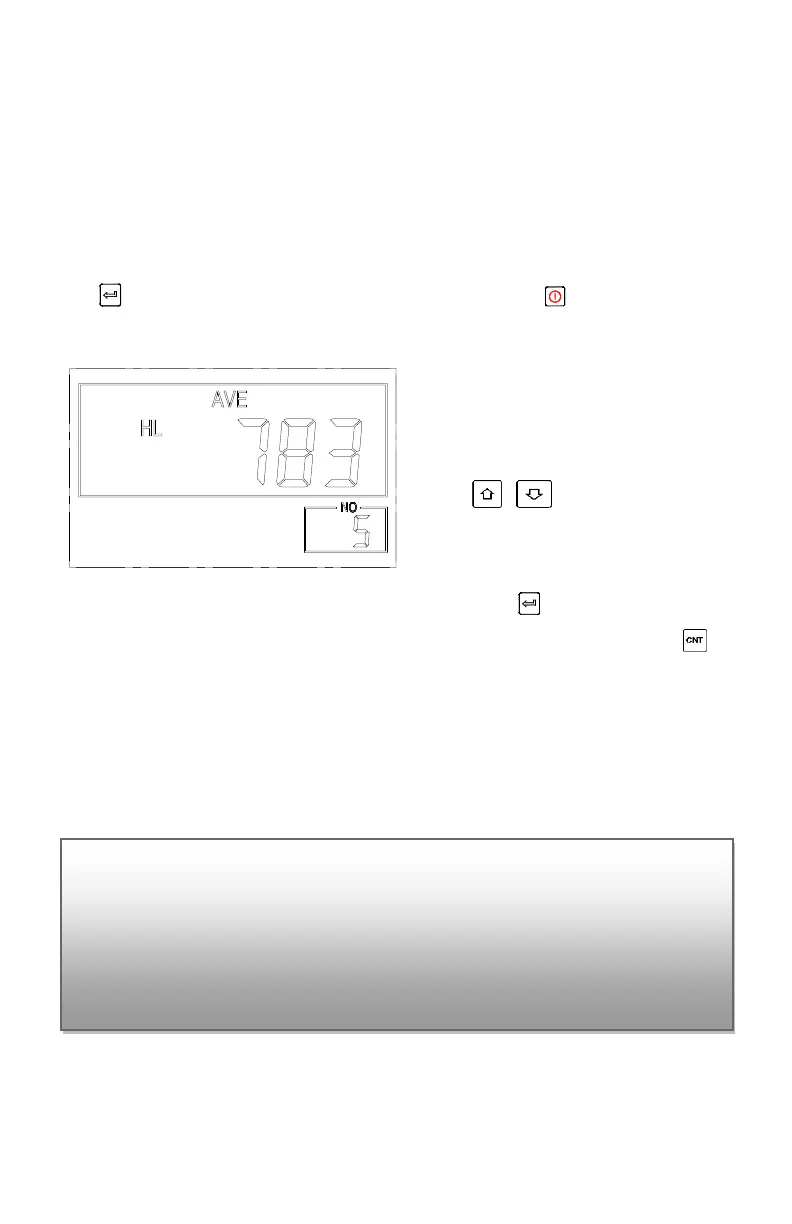

system. The calibration screen shows as below.

Take 5 tests on your standard

hardness block. The display will

show the average measured value

after measuring 5 times. Press

key to change to its

nominal value to match the value

shown on your test block.

Press key to confirm the

calibration. Or press the key to

cancel the calibration.

Range of adjustment: ±30HL.

The measurement parameters, including the material setting, the hardness scale and

the impact direction can’t be changed during calibration.

3.2 Impact Device Selection

Refer to Appendix Table 1 and Table 3 for selection of impact device.

Note:For verification, take 5 tests around the test block and get

your average. This average value should be within the acceptable

tolerance of the test block value. If this value exceeds the

allowable tolerance of the test block, a calibration should be

performed. See above.

Loading...

Loading...