WORKSHOP MANUAL

2 - INFORMATION FOR SERVICE CENTRES

EDITION

PAGE

8 /37

• and also:

- restore to proper working order any safety de-

vices which have been manipulated or removed;

- reassemble inefficient, damaged or missing

casings and protection covers;

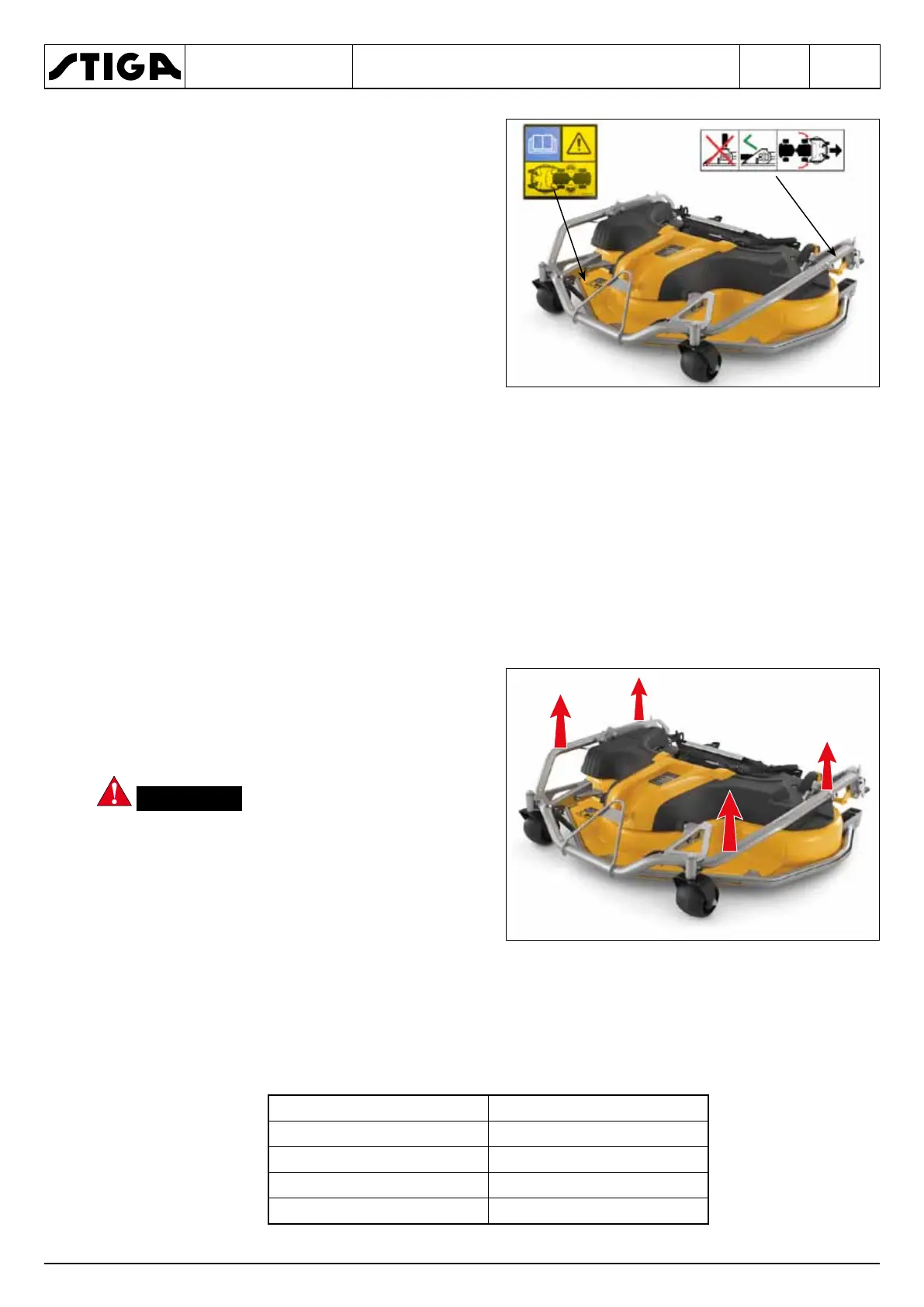

- replace illegible labels;

- clean the inside of the cutting deck with water

and a non-metal bristle brush;

- touch up the painted parts where the paint is

scratched or missing;

- not endorse any repair or modification on the

machine or the motor which results in a change

in performance or use that is incorrect or differ-

ent from the purpose for which it was designed and approved;

- warn the Customer that failure to comply with the above points automatically voids the warranty

and the responsibility of the Manufacturer.

All the operations can be carried out with the tools normally available at any good motoring Servic-

ing Centre.

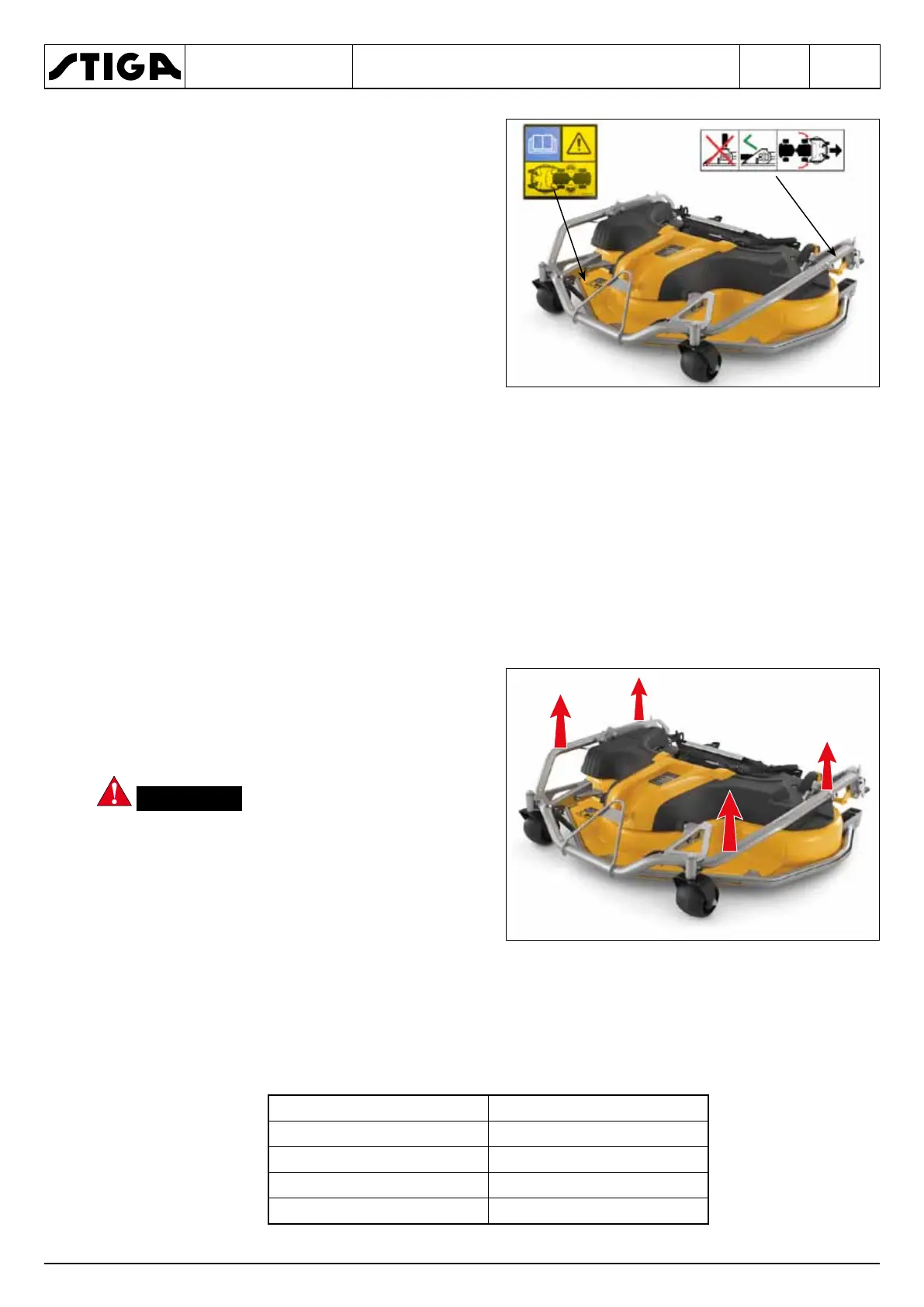

Pay utmost attention during the removal and as-

sembly of the equipment on the machine.

- To lift the equipment using

a hoist, use the two longitudinal elements

of the frame, taking into account the total

weight of about 70-75 kg and relative distri-

bution of the same.

The table shows the tightening torque settings for screws and nuts to be applied according to their

size, except for different situations indicated in the manual regarding a specific procedure.

Threading Tightening torque

M5 5 Nm

M6 9 Nm

M8 22 Nm

M10 45 Nm

Loading...

Loading...