3-34 ENGINE CONTROL SYSTEM

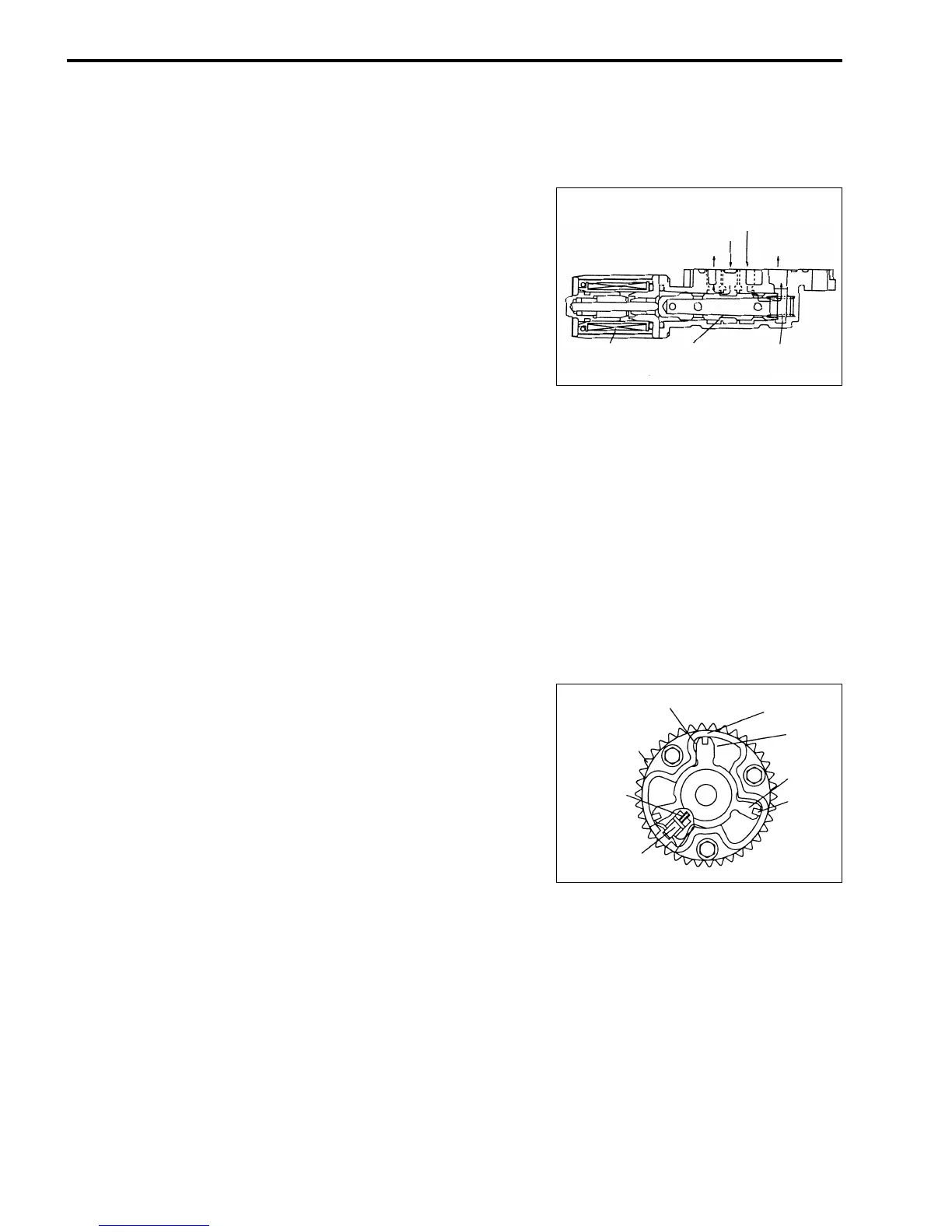

OCV (Oil Control Valve)

Two OCV are used, one installed on each (PORT/STBD) lower

camshaft housing.

RETARD OPERATION

When the duty ratio of the ECM is small, the OCV spool valve is

pushed away from the coil by spring force and engine oil pres-

sure is applied to the retard chamber.

Engine oil remaining in the advance chamber is drained out

through the spool valve.

ADVANCE OPERATION

When the duty ratio of the ECM is large, the spool valve is

towards the coil by magnetic force, compressing the spring and

applying engine oil pressure to the advance chamber side.

Engine oil remaining in the retard chamber side is drained out

through the spool valve.

RETAINING OPERATION

When the duty ratio of the ECM is medium, the OCV coil mag-

netic and return spring forces are equal. This positions the spool

valve between the advance and retard chamber, closing both oil

passages.

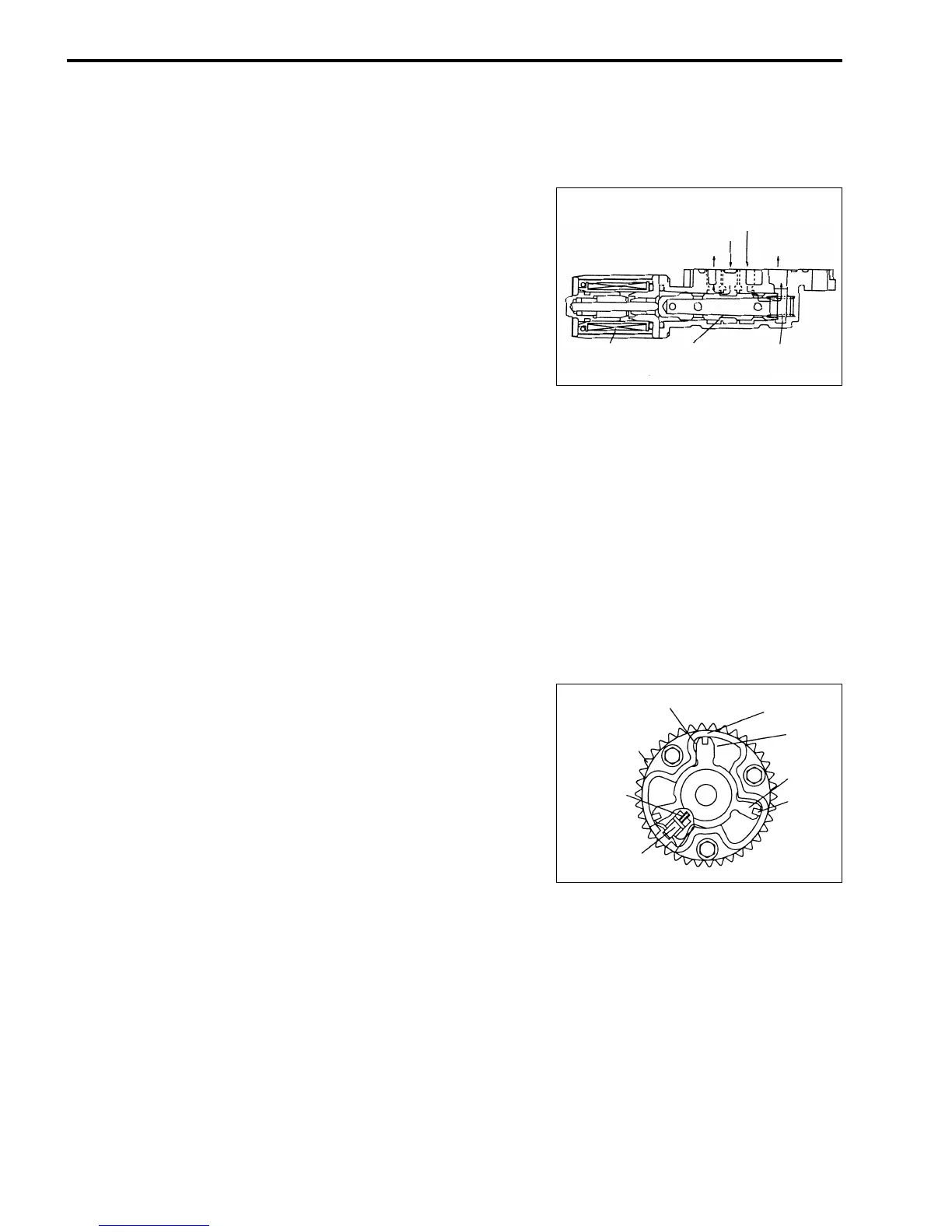

INTAKE CAM TIMING SPROCKET ASSY

Inside the intake cam timing sprocket assembly (VVT actuator),

there are separate advance chamber and retard chamber

formed by partition of the rotor.

The rotor moves inside the housing as engine oil pressure is

applied to the advance or retard chamber.

The intake cam timing sprocket is part of the sprocket housing

assembly. Since the rotor and intake camshaft are bolted

together, when the rotor moves inside the housing, a change of

phase angle takes place in the relative position between the

intake camshaft and intake cam timing sprocket. The rotor has a

spring pressured lock pin which engages with the housing when

spring force is greater than oil pressure, locking the rotor in the

most retarded position. This prevents a change of phase angle

between the intake camshaft and intake cam timing sprocket

when the engine oil pressure is low at engine start.

When the engine is started and the engine oil pressure is

applied to the advance chamber, the lock pin is forced up, com-

pressing the return spring, releasing the rotor and allowing the

VVT actuator to function.

Coil Spool valve

Spring

Engine oil pressure

Retard chamber

Advance chamber

Drain

Retard operation

Advance chamber

Housing

Retard

chamber

Rotor

Seal

Lock pin

Spring

Intake cam

timing sprocket

Loading...

Loading...