Manual Transmission/Transaxle: 5B-28

Countershaft and Reverse Idle Gear Inspection

S5JB0A5206020

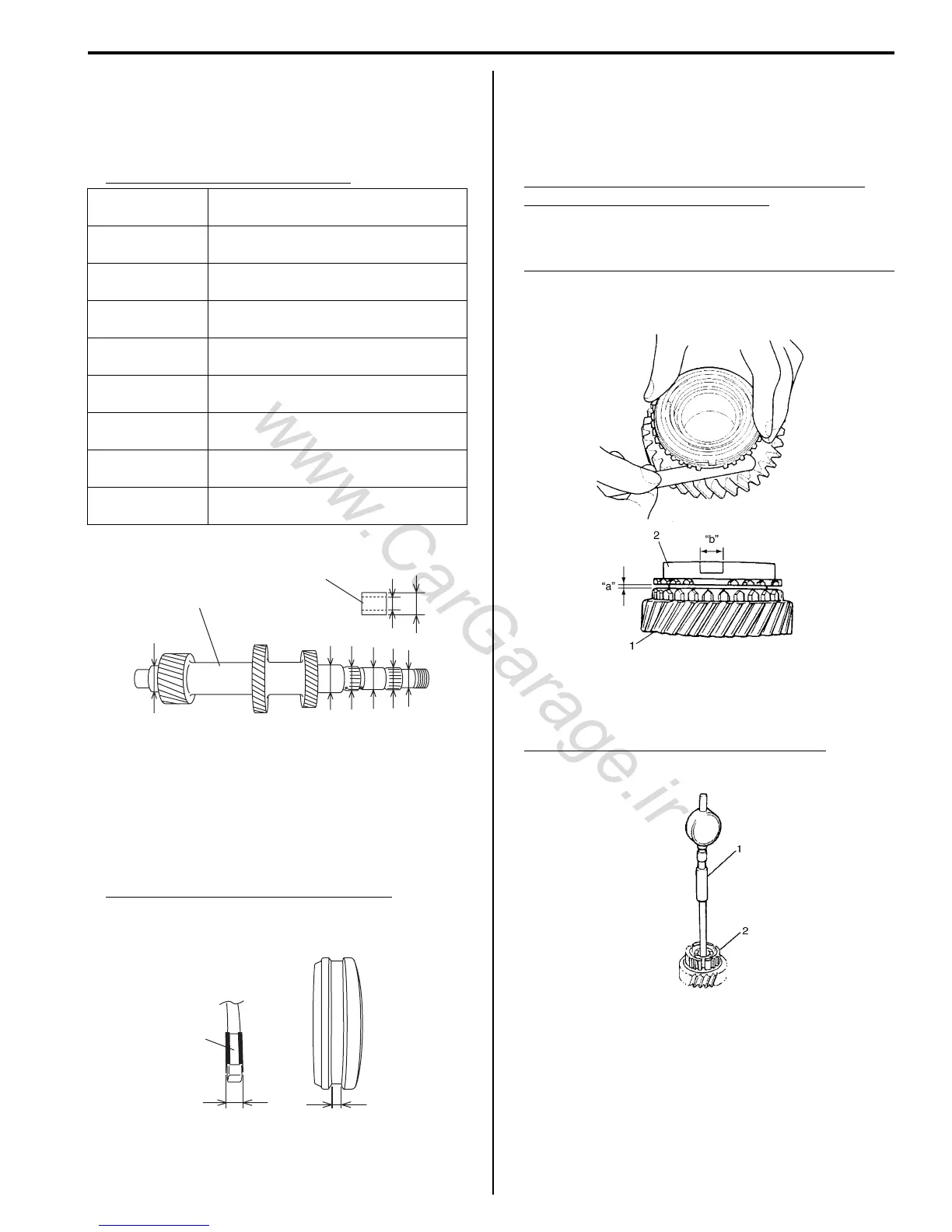

• Using micrometer, check diameter of countershaft (1)

and needle bush (2) as shown. If measured value is

out of specification, replace counter and/or bush.

Countershaft diameter (standard)

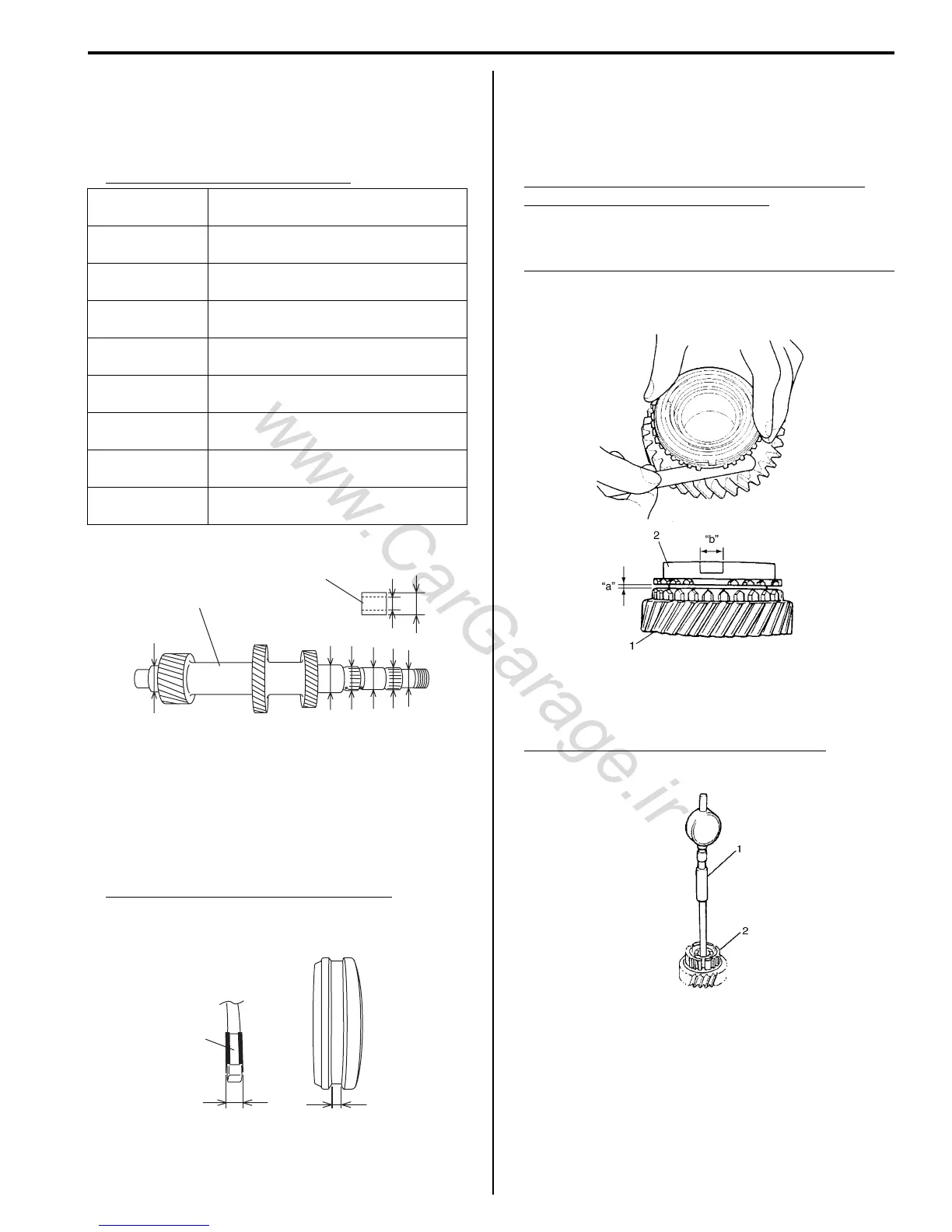

• Measure width “a” of low speed gear shift fork and

groove width “b” of low speed gear synchronizer

sleeve and then calculate clearance “c” as follows:

If clearance exceeds limit, replace fork bush (1) and

sleeve.

Clearance “c” between fork and sleeve

Standard: 0.3 – 0.5 mm (0.012 – 0.020 in.)

Limit: 1.0 mm (0.039 in.)

• Check clearance “a” between synchronizer ring (2)

and gear (1), key slot width “b” in synchronizer ring

and each chamfered tooth of gear and synchronizer

ring and replace with new one, if necessary. Also,

check gear tooth.

Clearance “a” between synchronizer ring and

gear (Countershaft) (1st and 2nd)

Standard: 1.0 – 1.4 mm (0.040 – 0.055 in.)

Service limit: 0.5 mm (0.020 in.)

Key slot width “b” (1st and 2nd synchronizer ring)

Standard: 10.0 – 10.2 mm (0.394 – 0.401 in.)

Limit: 10.45 mm (0.411 in.)

• Using cylinder gauge (1), check inside diameter of

countershaft 1st and 2nd gears (2). If measured value

exceeds specification, replace countershaft 5th gear.

Countershaft 1st and 2nd gears diameter

Standard: 40.000 – 40.025 mm (1.5748 – 1.5757 in.)

Measuring

portion

Standard

“a”

25.002 – 25.015 mm

(0.9843 – 0.9848 in.)

“b”

27.987 – 28.000 mm

(1.1019 – 1.1023 in.)

“c”

27.987 – 28.000 mm

(1.1019 – 1.1023 in.)

“d”

30.959 – 30.975 mm

(1.2189 – 1.2194 in.)

“e”

34.975 – 34.991 mm

(1.3770 – 1.3775 in.)

“f”

30.002 – 30.015 mm

(1.1812 – 1.1816 in.)

“g”

28.000 – 28.013 mm

(1.1023 – 1.1028 in.)

“h”

34.975 – 34.991 mm

(1.3770 – 1.3776 in.)

Clearance “c” = “b” – “a”

“c”

“d”

“e”

“f”

“g”

“h”

“b”

“a”

1

2

I5JB0A520078-01

1

“a” “b”

I5JB0A520055-01

I5JB0A520079-01

IYSQ01522122-01

Loading...

Loading...