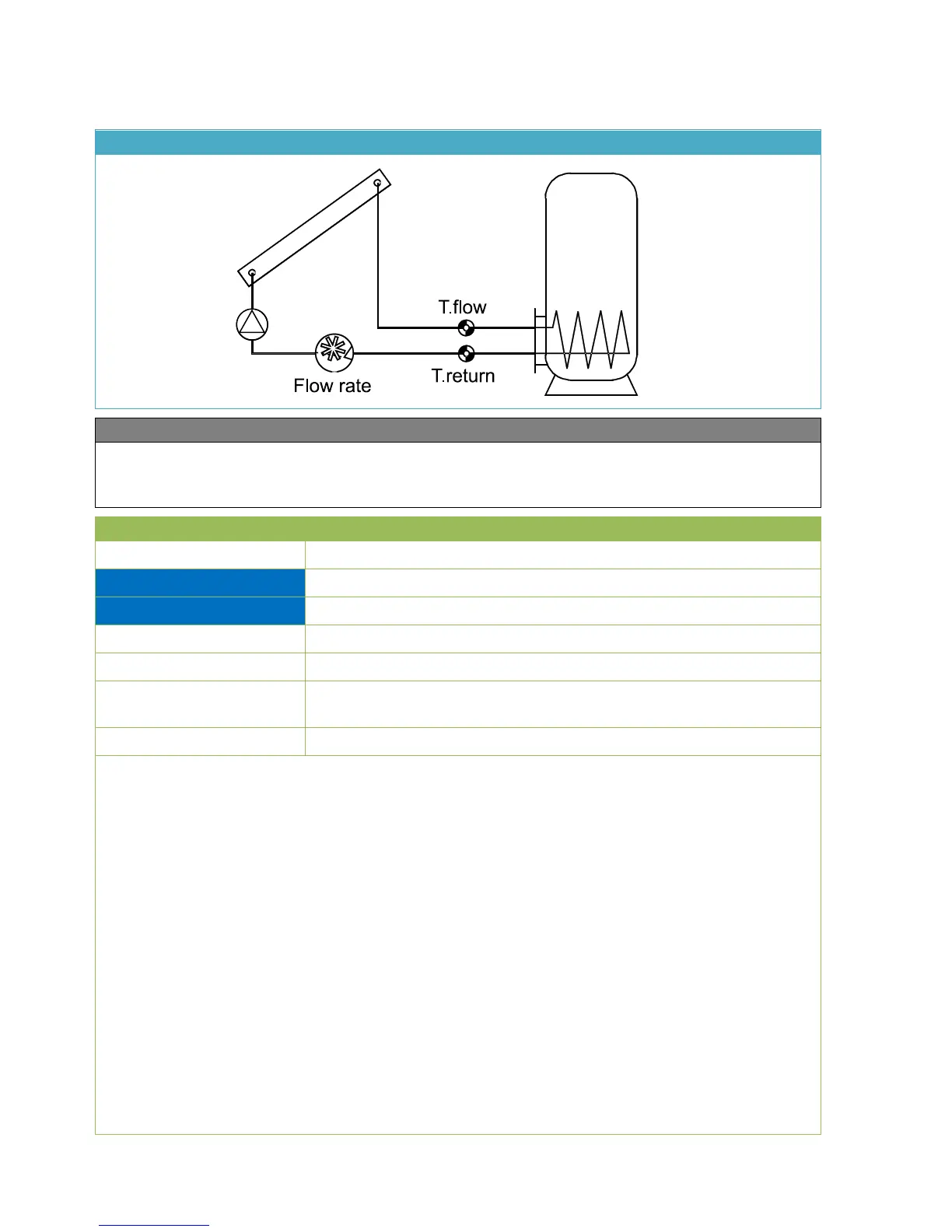

Calculation of thermal output and metering of thermal energy via the temperature differential

T.flow - T.return and the flow rate, and allowing for the antifreeze component in the heat transfer

medium.

➢ The BFPT1000 5x60MM sensors fitted in the KH ball valve from Technische Alternative

are particularly suitable for temperature measurement. The sensors can be removed with

little effort for the calibration process.

➢ With a solar thermal system, the collector sensor can also be used as the flow sensor. For

that to be possible, it must be installed in a sensor well at the flow outlet of the collector

header. However, the captured amount of heat will then also include the losses in the solar

flow line.

➢ Entering User as the source in the Flow rate input variable allows a fixed value to be

entered as the flow rate instead the flow rate captured by a flow sensor.

➢ The meter reset is carried out by a digital ON pulse or manually in the parameter menu. It

will delete all meter readings, in other words also those from previous periods. The meter

will be blocked as long as this input variable is set to ON. The meter reset also works when

Enable = Off.

➢ Specific heat capacity: This optional specification must be entered as a multiple of the unit

0.01 kJ/l*K as a dimensionless number. Example: Pure water has a heat capacity of 4.18

kJ/l*K at 20 °C, so a dimensionless value of 418 must be entered for this heat capacity (at

20 °C).

N.B.: The heat capacity of fluids is temperature-dependent. The value entered should

therefore be a variable value dependent on the temperature (e.g. from the Curve function).

Loading...

Loading...