Lubrication

GreasingtheMachine

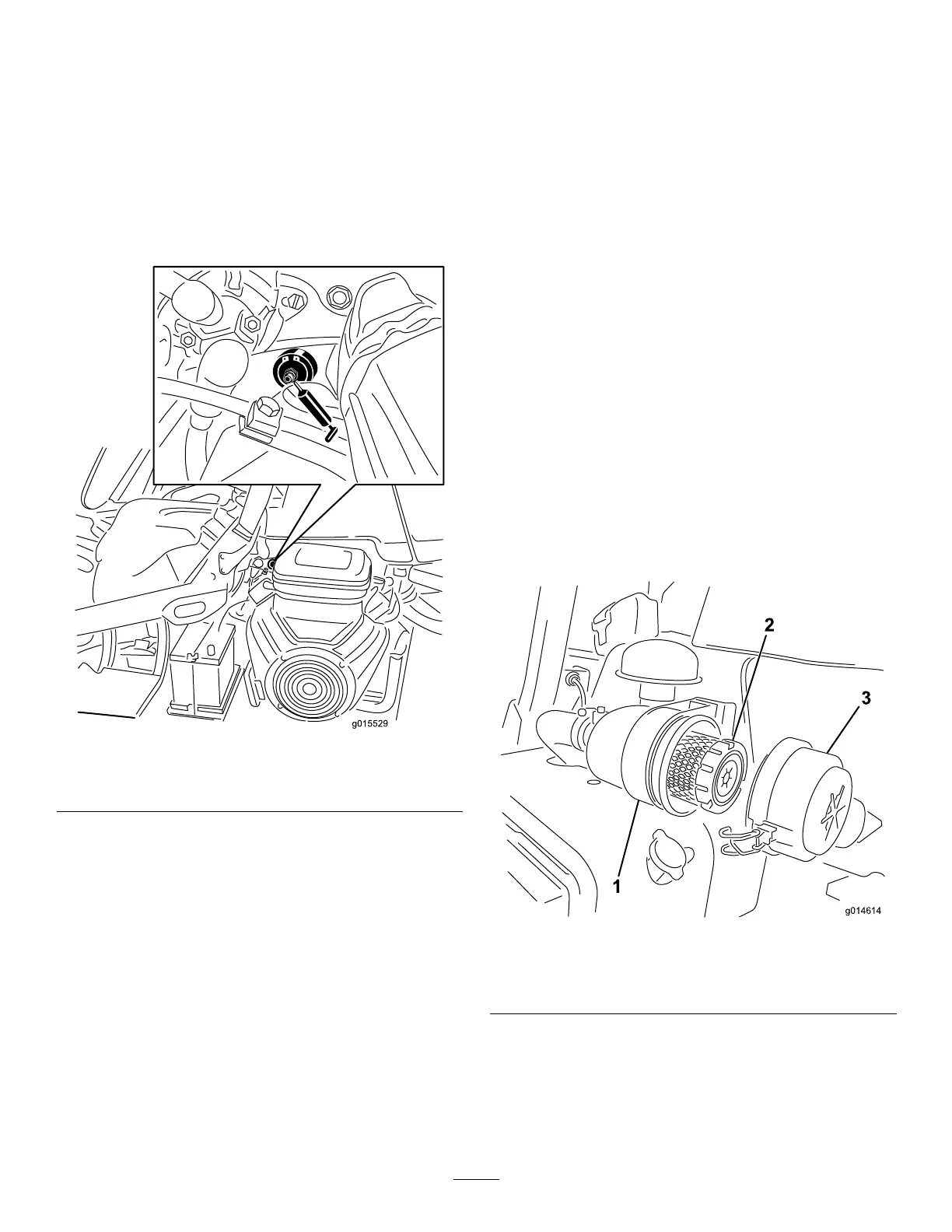

ServiceInterval:Every400hours

LubricatethegreasettingwithNo.2lithiumgrease.

1.Wipethegreasettingcleansothatyoudonot

forceforeignmatterintothebearingorbushing

(Figure29).

g015529

Figure29

Leftsideofthegasolinemodelshown;yourmodelmayvary

2.Pumpgreaseintothebearingorbushinguntil

thegreaseisvisible.Wipeupexcessgrease.

EngineMaintenance

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangethegovernorspeedoroverspeed

theengine.

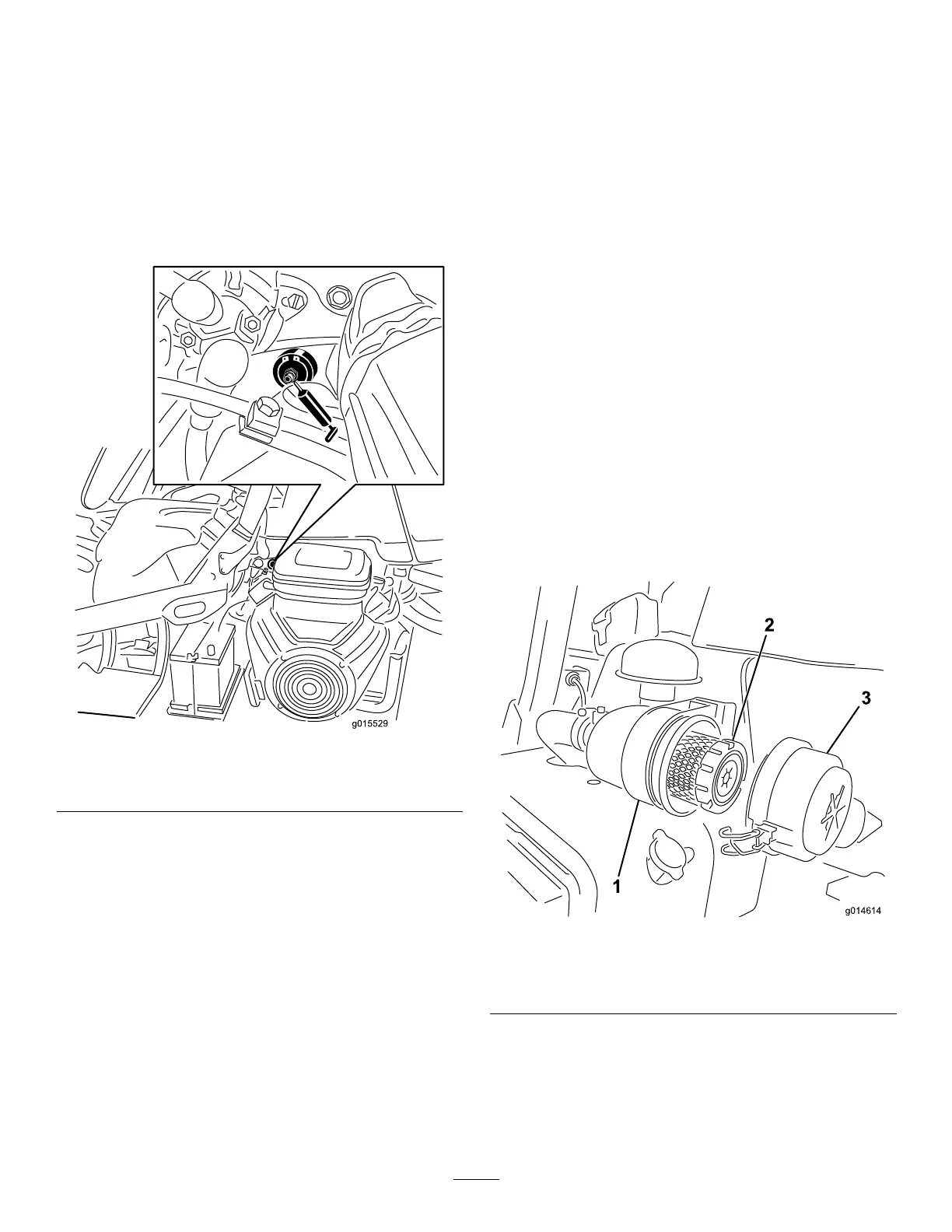

ServicingtheAirCleaner

ServiceInterval:Every200hours—Servicethe

air-cleanerlter(morefrequently

whenoperatingconditionsaredusty

ordirty).

•Checktheair-cleanerbodyfordamagewhich

couldcauseanairleak;replaceitifitisdamaged.

Checkthewholeintakesystemforleaks,damage,

orloosehoseclamps.

•Changingtheairlterbeforeitisnecessary

increasesthechanceofdirtenteringtheengine

whenthelterisremoved.

•Ensurethatthecoverisseatedcorrectlyandseals

withtheaircleanerbody.

1.Releasethelatchessecuringtheair-cleaner

covertotheair-cleanerbody(Figure30).

g014614

Figure30

1.Air-cleanerbody3.Air-cleanercover

2.Airlter

2.Removethecoverfromtheair-cleanerbody.

3.Beforeremovingthelter,uselowpressureair

(275kPa(40psi),cleananddry)tohelpremove

largeaccumulationsofdebrispackedbetween

theoutsideoftheprimarylterandthecanister.

Thiscleaningprocesspreventsdebrisgetting

36

Loading...

Loading...