Figure47

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplaceabentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesoftheblade.

A.Ifthedifferenceisgreaterthan3mm(1/8inch),

replacethebladewithanewblade;referto

RemovingtheBlades(page40)andInstallingthe

Blades(page41).

Note:Ifyoureplaceabentbladeandthe

dimensionobtainedcontinuestoexceed3mm

(1/8inch),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

6.Repeatthisprocedureoneachblade.

RemovingtheBlades

Replacesabladeifithitsasolidobject,ifitisoutofbalance,

orifitisbent.Toensureoptimumperformanceand

continuedsafetyconformanceofthemachine,usegenuine

Tororeplacementblades.Replacementbladesmadebyother

manufacturersmayresultinnon-conformancewithsafety

standards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,thecurvedwasher,andthe

bladefromthespindleshaft(Figure48).

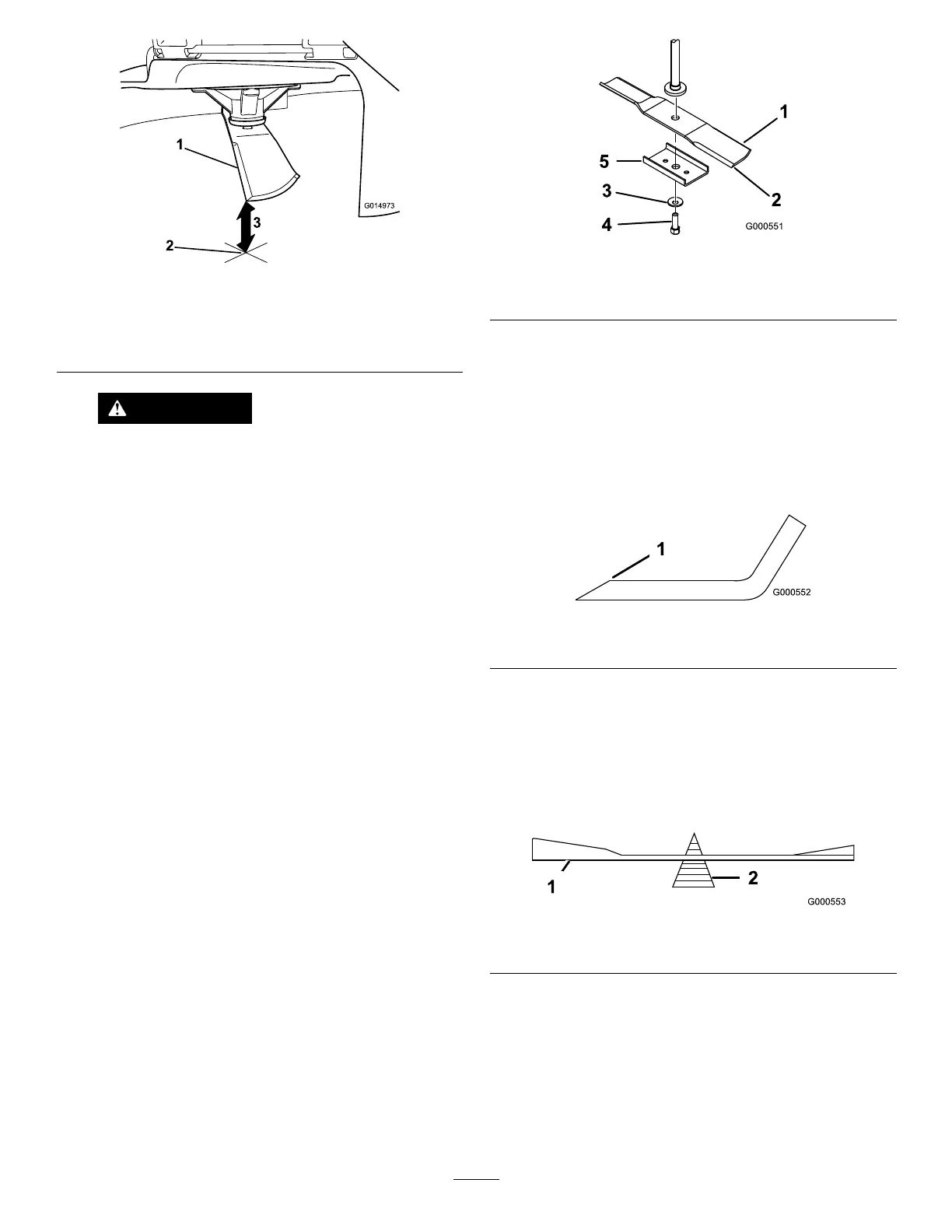

Figure48

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure49).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

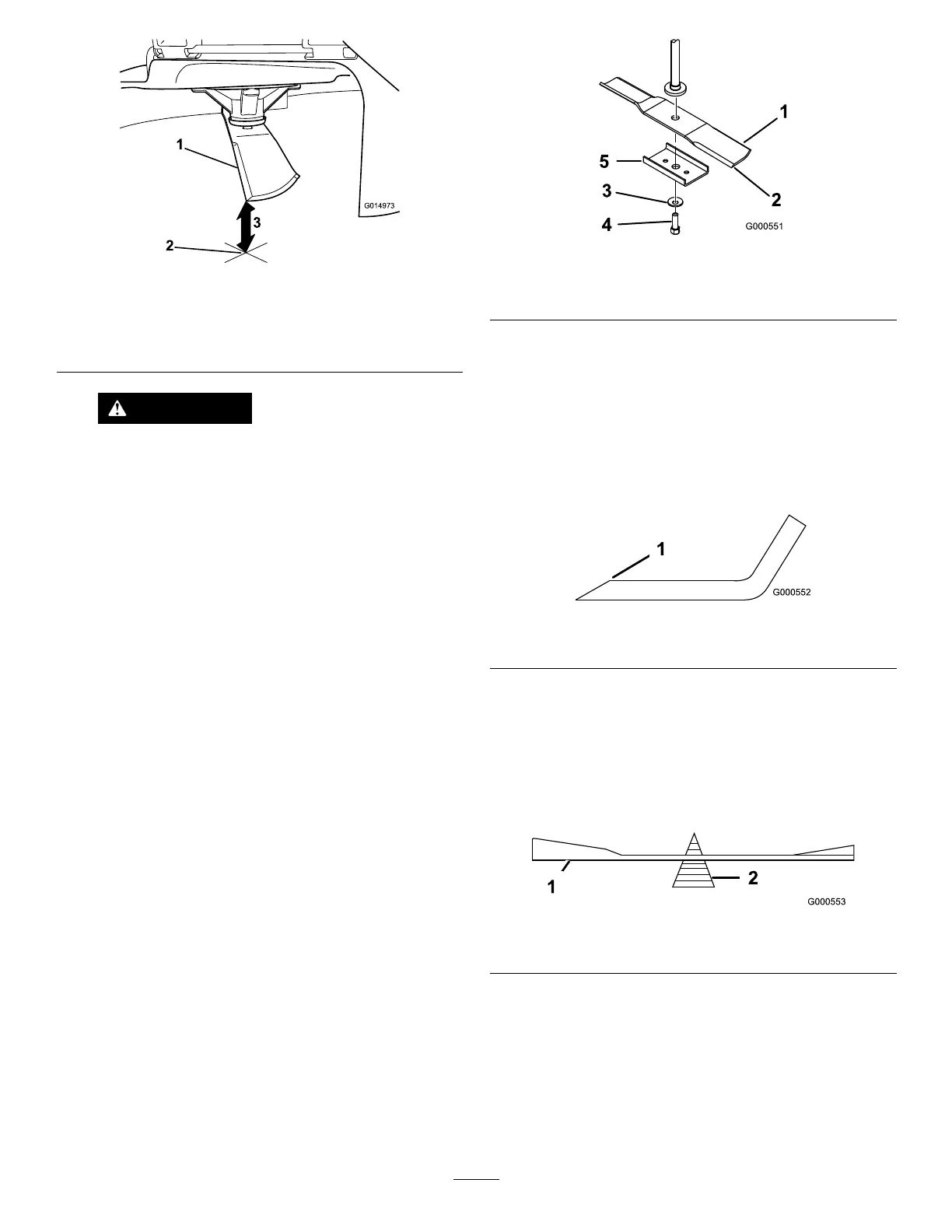

Figure49

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure50).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalanced,andcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure49).

Figure50

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeisbalanced.

40

Loading...

Loading...