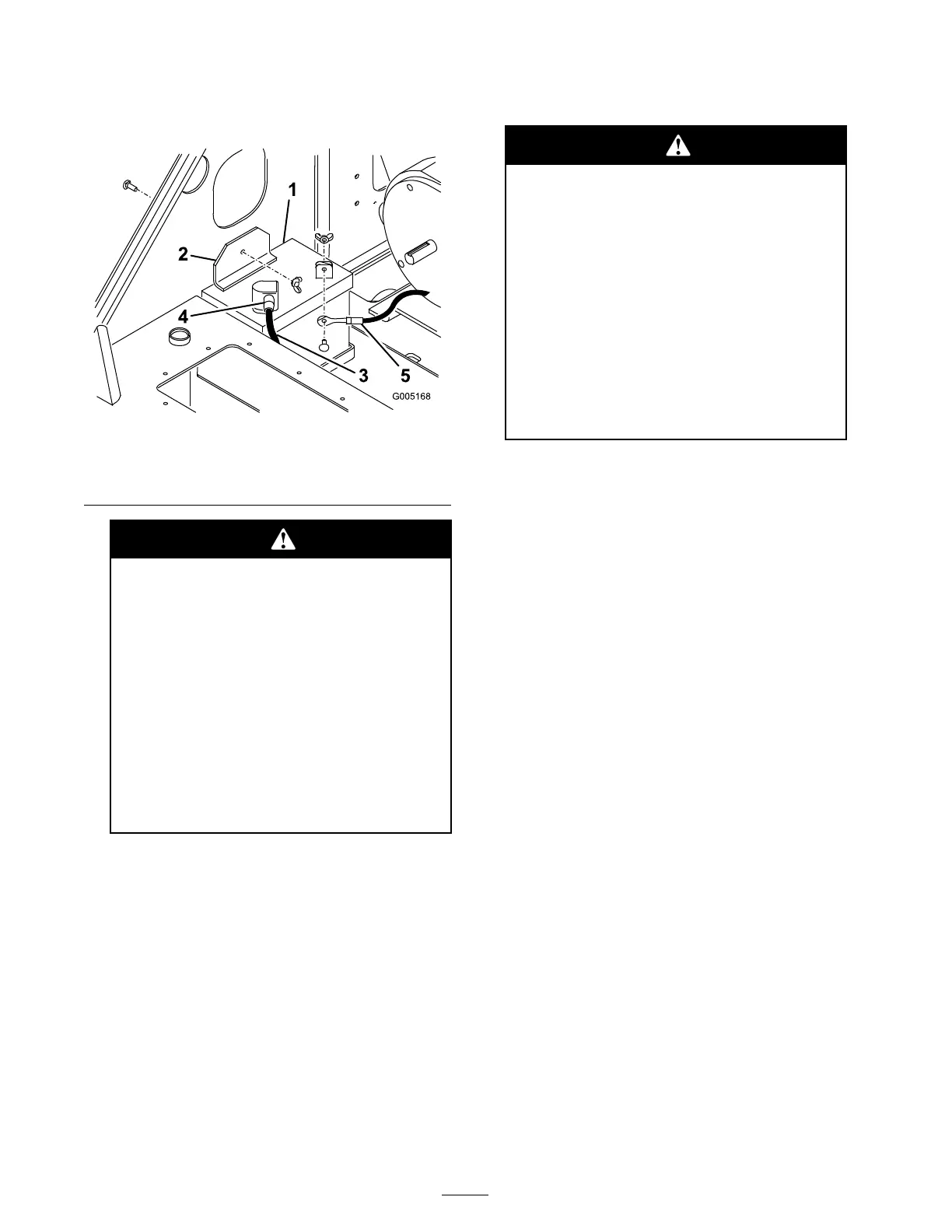

3. R emo v e the wing n ut and bolt securing the

batter y clamp and strip (under the clamp) and

remo v e the clamp and strip ( Figure 27 ).

Figure 27

1. Battery

4. Rubber cover

2. Battery clamp 5. Negative cable

3. Positive cable

Batter y ter minals or metal tools could

shor t a gainst metal components, causing

spar ks. Spar ks can cause the batter y

gasses to explode, r esulting in per sonal

injur y .

• W hen r emo ving or installing the

batter y , do not allo w the batter y

ter minals to touch an y metal par ts of

the traction unit.

• Do not allo w metal tools to shor t

betw een the batter y ter minals and

metal par ts of the traction unit.

4. Disconnect the neg ati v e (blac k) batter y cable

from the batter y , sa ving the bolt and n ut.

5. Disconnect the positi v e (red) batter y cable

from the batter y , sa ving the bolt and n ut.

6. Gently push the h y draulic hoses aside and lift

the batter y out of the c hassis .

7. Acti v ate the new batter y as directed on the

batter y labeling .

8. Install the batter y into the c hassis ( Figure 27 ).

9. Secure the batter y in the c hassis ( Figure 27 ).

10. Using the bolt and wing n ut supplied with the

batter y , connect the positi v e (red) cable to the

positi v e (+) batter y post ( Figure 27 ). Slide the

r ubber co v er o v er the batter y post.

Incor r ect batter y ca ble r outing could

dama ge the traction unit and ca bles,

causing spar ks. Spar ks can cause the

batter y gasses to explode, r esulting in

per sonal injur y .

• Al w ays disconnect the negati v e

(black) batter y ca ble bef or e

disconnecting the positi v e (r ed)

ca ble.

• Al w ays connect the positi v e (r ed)

batter y ca ble bef or e connecting the

negati v e (black) ca ble.

11. Using the bolt and wing n ut supplied with the

batter y , connect the neg ati v e (blac k) cable to

the neg ati v e (-) batter y post ( Figure 27 ).

Note: Ensure that the batter y cables do not

contact any shar p edg es or eac h other .

Servicing the Battery

Important: T he f ollo wing pr ocedur es

appl y when ser vicing a (dr y) batter y that has

r eplaced the original batter y . T he original

(w et) batter y does not r equir e ser vice.

Chec k the electrolyte lev el in the batter y ev er y 100

hours . Alw a ys k ee p the batter y clean and fully

c harg ed. Use a paper to w el to clean the batter y

case . If the batter y ter minals are cor roded, clean

them with a solution of four par ts w ater and one

par t baking soda. Apply a light coating of g rease

to the batter y ter minals to reduce cor rosion.

V oltag e: 12 v , 450 Cold Cranking Amps

Checking the Electrolyte Level

1. Stop the engine and remo v e the k ey .

2. R emo v e the 4 bolts securing the batter y co v er

and remo v e it from o v er the batter y .

3. Look at the side of the batter y . T he electrolyte

m ust be up to the Upper line ( Figure 28 ).

Do not allo w the electrolyte to fall belo w the

Lo w er line ( Figure 28 ).

30

Loading...

Loading...